Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blast Furnace Checker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

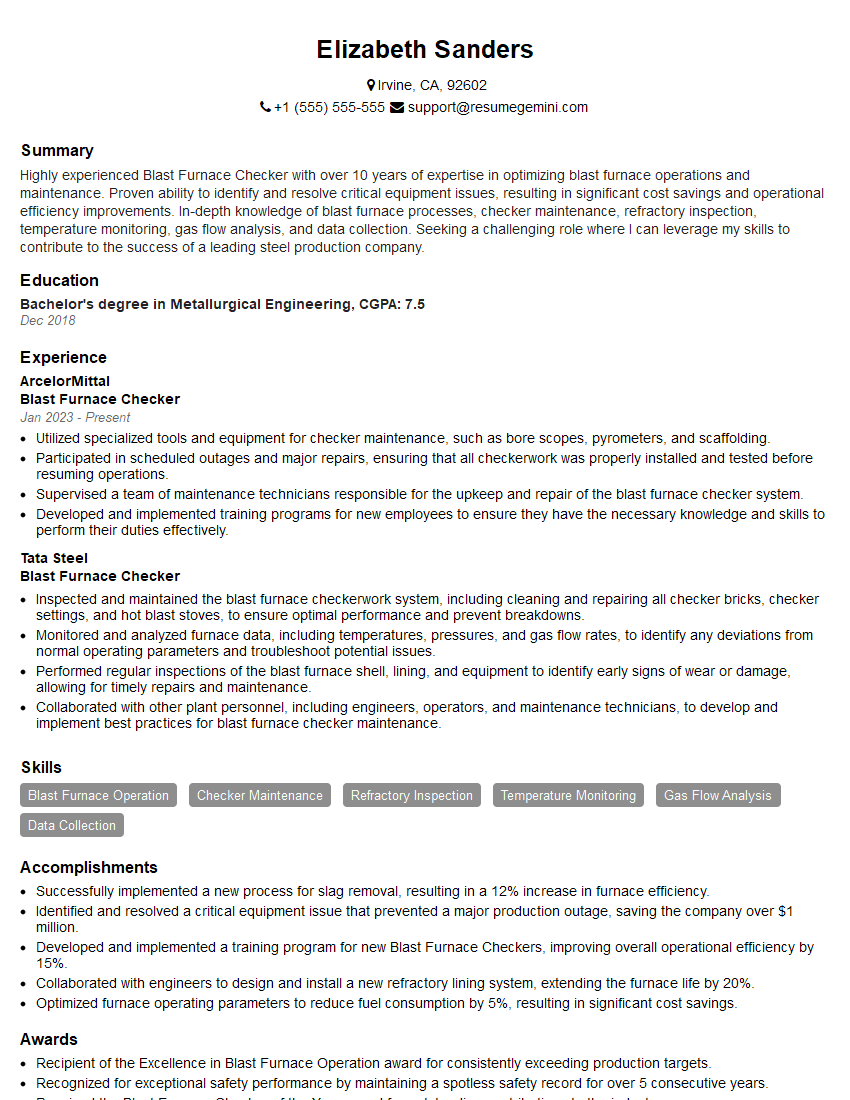

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Checker

1. What is the role of a Blast Furnace Checker?

The role of a Blast Furnace Checker is to ensure the smooth and efficient operation of the blast furnace by performing various critical tasks:

- Monitoring and analyzing the performance of the blast furnace and its various components to identify potential issues and areas for improvement.

- Conducting regular inspections and maintenance of the blast furnace and its equipment, including the checker brickwork, hot blast stoves, and gas cleaning systems.

- Interpreting data from sensors, instruments, and other sources to assess the condition of the blast furnace and its components, and taking appropriate actions to maintain optimal performance.

2. Describe the process of blast furnace operation and the role of the checker brickwork?

Function of Checker Brickwork

- The checker brickwork serves as a heat exchanger, absorbing and releasing heat to preheat the incoming air blast entering the blast furnace.

- By preheating the air blast, the checker brickwork helps to increase the temperature of the blast furnace, promoting more efficient combustion and iron production.

Process of Blast Furnace Operation

- Iron ore, coke, and limestone are charged into the blast furnace from the top.

- Hot air blast, preheated by the checker brickwork, is blown into the furnace from the bottom.

- The hot air blast reacts with the coke, generating heat and reducing the iron ore to molten iron.

- Molten iron and slag are tapped from the furnace at regular intervals.

3. Explain the importance of maintaining the correct temperature profile in the blast furnace?

Maintaining the correct temperature profile in the blast furnace is crucial for efficient iron production and overall furnace health:

- Ensuring proper melting and reduction of iron ore to molten iron.

- Preventing premature melting of the burden materials, leading to reduced iron yield and increased slag volume.

- Minimizing heat losses and energy consumption by optimizing the temperature distribution throughout the furnace.

- Maximizing the production rate and efficiency of the blast furnace operation.

4. What are the common problems encountered in blast furnace checker brickwork and how do you address them?

Common problems encountered in blast furnace checker brickwork include:

- Clogging: Dust and debris accumulation can clog the checker bricks, reducing their heat transfer efficiency.

- Erosion: High temperatures and gas flow can erode the checker bricks over time, weakening their structure and reducing their effectiveness.

- Spalling: Thermal cycling and chemical reactions can cause the checker bricks to spall, creating gaps and reducing the overall heat exchange surface area.

To address these problems, regular inspections, cleaning, and maintenance are essential:

- Using soot blowers or air lances to remove dust and debris.

- Replacing damaged or eroded checker bricks.

- Applying protective coatings to minimize spalling.

5. Describe the methods used to monitor and evaluate the performance of the blast furnace checker brickwork?

- Visual Inspection: Regular visual inspections are conducted to check for cracks, spalling, and other visible signs of damage.

- Thermographic Imaging: Infrared cameras are used to detect temperature variations and identify areas of poor heat transfer.

- Ultrasonic Testing: Ultrasonic waves are passed through the checker brickwork to detect internal defects or voids.

- Data Analysis: Data from sensors and instruments monitoring the blast furnace operation, such as air flow, pressure, and temperature, can provide insights into the performance of the checker brickwork.

6. Explain the importance of coordinating with other departments in the blast furnace operation?

Coordinating with other departments is essential for the smooth and efficient operation of the blast furnace:

- Ironmaking: To ensure a steady supply of raw materials and coordination of iron production.

- Maintenance: To plan and schedule maintenance activities, minimizing disruptions to the blast furnace operation.

- Quality Control: To monitor and control the quality of raw materials and finished products.

- Environmental: To comply with environmental regulations and minimize emissions.

7. What are the safety precautions that must be observed when working in the vicinity of a blast furnace?

- Wearing appropriate personal protective equipment (PPE), such as flame-resistant clothing, safety glasses, and respirators.

- Following established safety procedures and protocols.

- Being aware of potential hazards, such as hot surfaces, molten metals, and hazardous gases.

- Maintaining a safe distance from the blast furnace and its components.

- Receiving proper training and authorization before performing any tasks near the blast furnace.

8. How do you stay updated with the latest industry best practices and technological advancements in blast furnace operation?

- Attending industry conferences and workshops.

- Reading technical publications and journals.

- Participating in online forums and discussion groups.

- Consulting with experts and seeking guidance from experienced professionals.

- Staying informed about new technologies and innovations through research and development.

9. What motivates you to excel in the role of a Blast Furnace Checker?

I am highly motivated to excel in the role of a Blast Furnace Checker due to my:

- Passion for the iron and steel industry and its critical role in modern society.

- Strong understanding of blast furnace operations and the importance of checker brickwork performance.

- Analytical mindset and problem-solving abilities to identify and address issues proactively.

- Commitment to safety and adherence to best practices.

- Desire to contribute to the efficient and productive operation of the blast furnace.

10. Why should we consider you for this position as a Blast Furnace Checker?

I believe I am a highly qualified candidate for the position of Blast Furnace Checker due to my:

- Extensive knowledge and experience in blast furnace operations, particularly in checker brickwork maintenance and performance optimization.

- Proven ability to monitor, analyze, and troubleshoot complex technical issues.

- Strong communication and interpersonal skills to effectively collaborate with colleagues and management.

- Commitment to continuous learning and staying up-to-date with industry advancements.

- Dedication to safety and maintaining a high level of operational excellence.

I am confident that I can leverage my skills and experience to make significant contributions to your team and the overall success of the blast furnace operation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Furnace Checkers play a crucial role in the efficient operation of blast furnaces in the steel industry. Their primary responsibilities involve:

1. Monitoring and Maintaining Blast Furnace Operations

Checkers closely monitor the performance of the blast furnace, ensuring its smooth and efficient operation. They observe and interpret various parameters such as temperature, pressure, and gas composition to identify any deviations or anomalies.

- Monitor furnace parameters, including temperatures, pressures, and gas composition.

- Detect and troubleshoot operational issues, such as leaks, blockages, and fluctuations in performance.

- Record and analyze data to identify trends and potential areas for improvement.

2. Inspecting and Maintaining Equipment

Checkers are responsible for regularly inspecting and maintaining the blast furnace and its auxiliary equipment. They ensure that all components are functioning correctly and adhere to safety standards.

- Conduct scheduled inspections of furnace components, including tuyères, burners, and cooling systems.

- Identify and replace worn or damaged parts.

- Lubricate and adjust equipment to ensure optimal performance.

3. Assisting in Process Optimization

Checkers actively participate in efforts to improve the efficiency and productivity of the blast furnace process. They analyze data and propose modifications to operating parameters or equipment designs.

- Evaluate process data to identify areas for improvement in furnace performance.

- Collaborate with engineers and technicians to develop and implement process optimizations.

- Implement improved operating practices to enhance furnace productivity and efficiency.

4. Ensuring Safety and Compliance

Safety is paramount in blast furnace operations. Checkers are responsible for adhering to safety protocols and ensuring that all equipment and procedures comply with regulatory standards.

- Monitor safety systems and report any hazards or potential risks.

- Enforce adherence to safety guidelines and procedures.

- Participate in safety training and drills.

Interview Tips

Preparing for a Blast Furnace Checker interview requires a combination of technical knowledge and an understanding of the industry’s best practices. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Familiarize yourself with the steel production industry and the specific company you’re interviewing with. Research their history, products, and market position.

- Visit the company’s website and study their annual reports.

- Read industry publications and news articles to understand current trends and challenges.

- Connect with professionals in the field through networking events or LinkedIn.

2. Highlight Your Technical Skills

Emphasize your expertise in blast furnace operations and maintenance. Showcase your understanding of process parameters, equipment components, and safety protocols.

- Describe your experience with monitoring and troubleshooting blast furnace systems.

- Provide examples of how you have improved furnace performance through process optimization.

- Explain your knowledge of safety regulations and best practices in the industry.

3. Demonstrate Your Problem-Solving Abilities

Interviewers will assess your ability to analyze problems and develop effective solutions. Prepare for questions that require you to troubleshoot hypothetical scenarios or describe your approach to resolving past issues.

- Use the STAR method (Situation, Task, Action, Result) to describe your problem-solving experience.

- Quantify your achievements and provide specific examples of how your actions led to improvements.

- Be prepared to discuss challenges you’ve faced and how you overcame them.

4. Prepare for Behavioral Questions

Behavioral interview questions focus on your past experiences and behaviors. They are designed to assess your teamwork skills, communication style, and commitment to safety.

- Practice answering questions about your ability to work effectively in a team.

- Describe your experience in communicating complex technical information to others.

- Explain how you prioritize safety in your work and what steps you take to mitigate risks.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. It also gives you an opportunity to clarify any areas that you’re unsure about.

- Ask about the company’s plans for future growth or innovation.

- Inquire about the specific challenges and opportunities associated with the Blast Furnace Checker role.

- Ask about the company’s commitment to safety and environmental sustainability.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blast Furnace Checker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.