Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Blast Furnace Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Blast Furnace Helper so you can tailor your answers to impress potential employers.

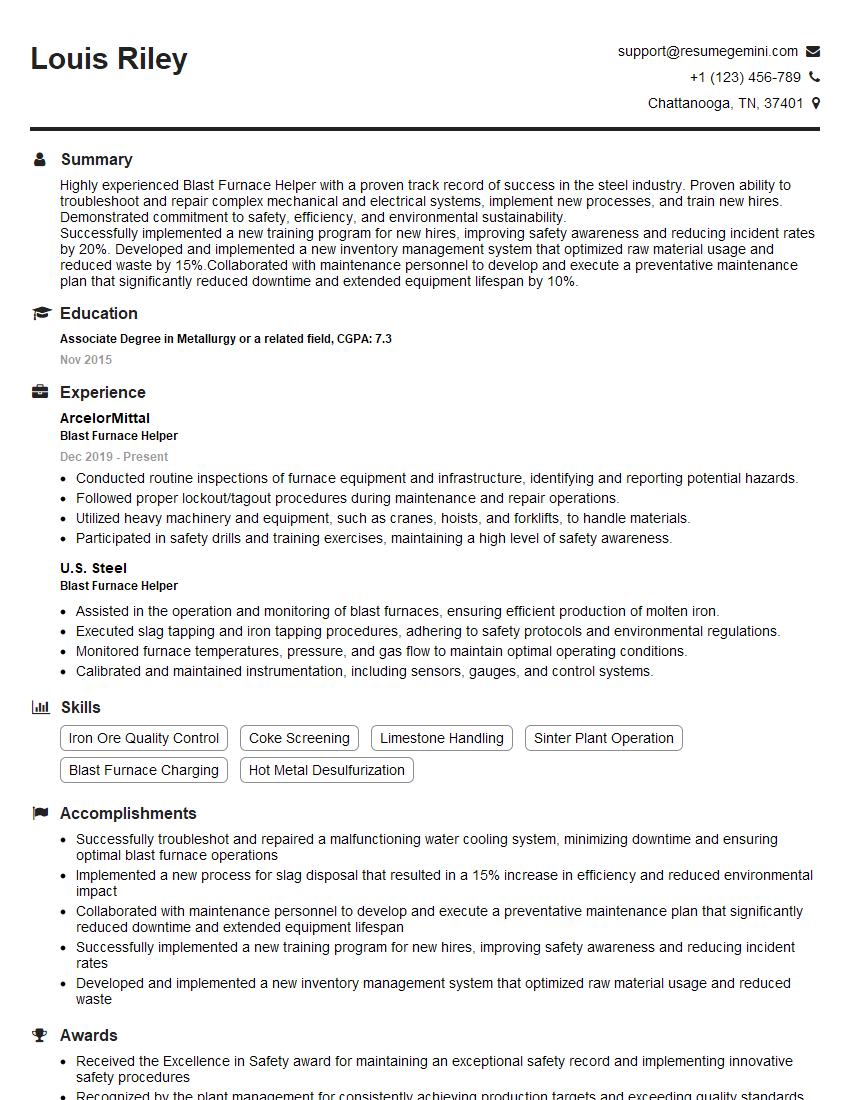

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Helper

1. What are the key responsibilities of a Blast Furnace Helper?

As a Blast Furnace Helper, my key responsibilities would likely include:

- Assisting in the operation and maintenance of the blast furnace

- Monitoring and controlling the furnace’s temperature, pressure, and other operating parameters

- Performing routine inspections and maintenance tasks

- Responding to emergencies and implementing safety procedures

2. Describe the process of charging the blast furnace.

Raw material preparation

- Iron ore, coke, and limestone are the main raw materials used in a blast furnace.

- Iron ore is mined and then crushed into small pieces.

- Coke is produced by heating coal in the absence of air.

- Limestone is used as a flux to remove impurities from the iron ore.

Charging the furnace

- The raw materials are charged into the blast furnace in layers.

- The bottom layer is coke, followed by a layer of iron ore, and then a layer of limestone.

- This process is repeated until the furnace is full.

3. What are the safety precautions that must be taken when working around a blast furnace?

Working around a blast furnace involves various hazards, so it’s essential to adhere to strict safety precautions:

- Always wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, earplugs, and heat-resistant clothing.

- Be aware of the potential for extreme heat and take measures to prevent burns.

- Stay clear of moving machinery and hot metal.

- Follow established procedures for operating the furnace and handling materials.

- Be familiar with emergency procedures and know where to locate safety equipment.

4. What are the different types of iron produced by a blast furnace?

Blast furnaces produce various types of iron, depending on the specific process and raw materials used:

- Hot metal: Liquid iron tapped directly from the blast furnace, containing about 4% carbon.

- Pig iron: Solid iron obtained by casting hot metal into molds, with a higher carbon content (about 4-5%).

- Cast iron: Similar to pig iron but with a higher carbon content (above 5%) and other alloying elements added to improve its properties.

- Wrought iron: A low-carbon iron produced by a different process, known for its malleability and resistance to corrosion.

5. How is the quality of iron produced by a blast furnace controlled?

To ensure the desired quality of iron produced by a blast furnace, several measures are taken:

- Raw material selection: Choosing high-quality iron ore, coke, and limestone with consistent properties.

- Process control: Monitoring and adjusting various operating parameters, such as temperature, pressure, and gas flow, to optimize the reduction process.

- Slag management: Controlling the formation and composition of slag, a byproduct of the process, to remove impurities from the iron.

- Quality testing: Regularly testing the produced iron to ensure it meets the desired specifications before being used for further processing.

6. What are the environmental considerations associated with blast furnace operations?

Blast furnace operations involve certain environmental considerations that need to be addressed:

- Air pollution: The process generates significant amounts of waste gases, including carbon dioxide, carbon monoxide, and particulate matter, which require proper treatment and control systems.

- Water consumption: Blast furnaces require a large amount of water for cooling and other processes, which must be managed efficiently to minimize wastage.

- Waste disposal: Slag, a byproduct of the process, must be disposed of or utilized responsibly to prevent environmental contamination.

- Energy consumption: Blast furnace operations are energy-intensive, so measures to improve energy efficiency and reduce greenhouse gas emissions are crucial.

7. What are the key performance indicators (KPIs) used to evaluate the efficiency of a blast furnace?

Various KPIs are used to assess the efficiency and performance of a blast furnace:

- Production rate: The amount of iron produced by the furnace per unit of time.

- Fuel consumption: The amount of coke or other fuel used per tonne of iron produced.

- Slag volume: The amount of slag produced per tonne of iron produced.

- Energy efficiency: The amount of energy consumed per tonne of iron produced.

- Environmental performance: The levels of emissions and waste generated during the process.

8. How does the use of technology, such as automation and sensors, impact blast furnace operations?

Technology plays a significant role in modern blast furnace operations:

- Automation: Automated systems are used to control various aspects of the furnace’s operation, including charging, temperature regulation, and slag removal.

- Sensors: Sensors are used to monitor and collect data on operating parameters, allowing for real-time adjustments and optimization.

- Data analytics: Advanced data analytics techniques are used to analyze the vast amount of data generated by sensors, providing insights into process efficiency and areas for improvement.

- Predictive maintenance: Predictive maintenance systems use data analysis to anticipate potential equipment failures, enabling proactive maintenance and minimizing downtime.

9. What are the emerging trends and innovations in blast furnace technology?

The blast furnace industry is constantly evolving, with new technologies and innovations emerging:

- Improved energy efficiency: Research is ongoing to develop more energy-efficient blast furnace designs and processes.

- Reduced emissions: Innovations aim to minimize greenhouse gas emissions and other pollutants generated by blast furnace operations.

- Alternative fuel sources: Exploring the use of alternative fuels, such as biomass and natural gas, to reduce reliance on fossil fuels.

- Process optimization: Advanced modeling and simulation techniques are used to optimize blast furnace operations and improve productivity.

10. How do you stay updated with the latest advancements in blast furnace technology?

To stay informed about the latest advancements in blast furnace technology, I actively engage in the following practices:

- Industry publications: Subscribe to and read industry journals, magazines, and technical reports.

- Conferences and seminars: Attend industry conferences, seminars, and workshops to learn about new technologies and best practices.

- Online resources: Explore reputable websites, research papers, and online forums dedicated to blast furnace technology.

- Networking: Connect with professionals in the field through LinkedIn, industry events, and professional organizations.

- Continuing education: Pursue online courses or specialized training programs to enhance my knowledge and skills in blast furnace technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blast Furnace Helper plays a crucial role in the operation of a blast furnace, assisting in the production of molten iron. Their key responsibilities include:

1. Furnace Operation

Assist in preparing and operating the blast furnace, including charging raw materials, controlling gas flow, and monitoring equipment.

- Unload raw materials, such as iron ore, coke, and limestone, into the furnace.

- Operate and maintain equipment used in the charging process, such as conveyors, hoists, and cranes.

2. Process Monitoring

Monitor and record furnace operating parameters, such as temperature, pressure, and gas composition, to ensure efficient and safe operation.

- Conduct regular inspections of furnace equipment for signs of wear or damage.

- Take corrective actions as needed to maintain optimal furnace performance.

3. Equipment Maintenance

Perform basic maintenance and repairs on furnace equipment, such as replacing worn parts and cleaning systems.

- Clean and maintain pumps, valves, and piping systems used in the furnace process.

- Replace or repair damaged equipment, such as refractory linings and water-cooling systems.

4. Safety and Compliance

Adhere to safety regulations and follow established operating procedures to ensure a safe and compliant work environment.

- Wear appropriate personal protective equipment (PPE) while working in the furnace area.

- Follow lockout/tagout procedures when performing maintenance on furnace equipment.

Interview Preparation Tips

To ace an interview for a Blast Furnace Helper position, follow these preparation tips:

1. Research the Role and Company

Thoroughly research the specific responsibilities of the role and the company’s operations. This will demonstrate your interest and show that you have a good understanding of the job requirements.

- Review the job description and company website for detailed information about the position.

- Visit industry-related forums and articles to gain insights into the role and the company’s reputation.

2. Highlight Relevant Experience

Emphasize your prior experience in industrial settings, particularly in furnace operation or maintenance. Quantify your accomplishments whenever possible to showcase your contributions.

- Describe your involvement in charging, monitoring, or maintaining furnace equipment in previous roles.

- Provide specific examples of how you contributed to improving furnace efficiency or safety.

3. Demonstrate Safety and Compliance Knowledge

Stress your understanding of safety regulations and compliance procedures in industrial environments. This is essential in a role that involves working with hazardous materials and heavy equipment.

- Explain your experience with lockout/tagout procedures and personal protective equipment (PPE).

- Discuss your knowledge of industry-specific regulations, such as those related to furnace emissions and environmental protection.

4. Prepare for Technical Questions

Expect technical questions to assess your knowledge of blast furnace operations and maintenance. Be prepared to discuss topics such as furnace charging, gas flow control, and refractory lining repair.

- Review basic principles of blast furnace operation, including the role of raw materials and gas flow.

- Practice troubleshooting common furnace problems and describing potential solutions.

5. Ask Informed Questions

Asking thoughtful questions during the interview shows engagement and interest. Prepare questions that demonstrate your curiosity about the role, the company, and the industry.

- Inquire about the company’s production goals and the specific challenges involved in meeting them.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blast Furnace Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blast Furnace Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.