Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blast Furnace Keeper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

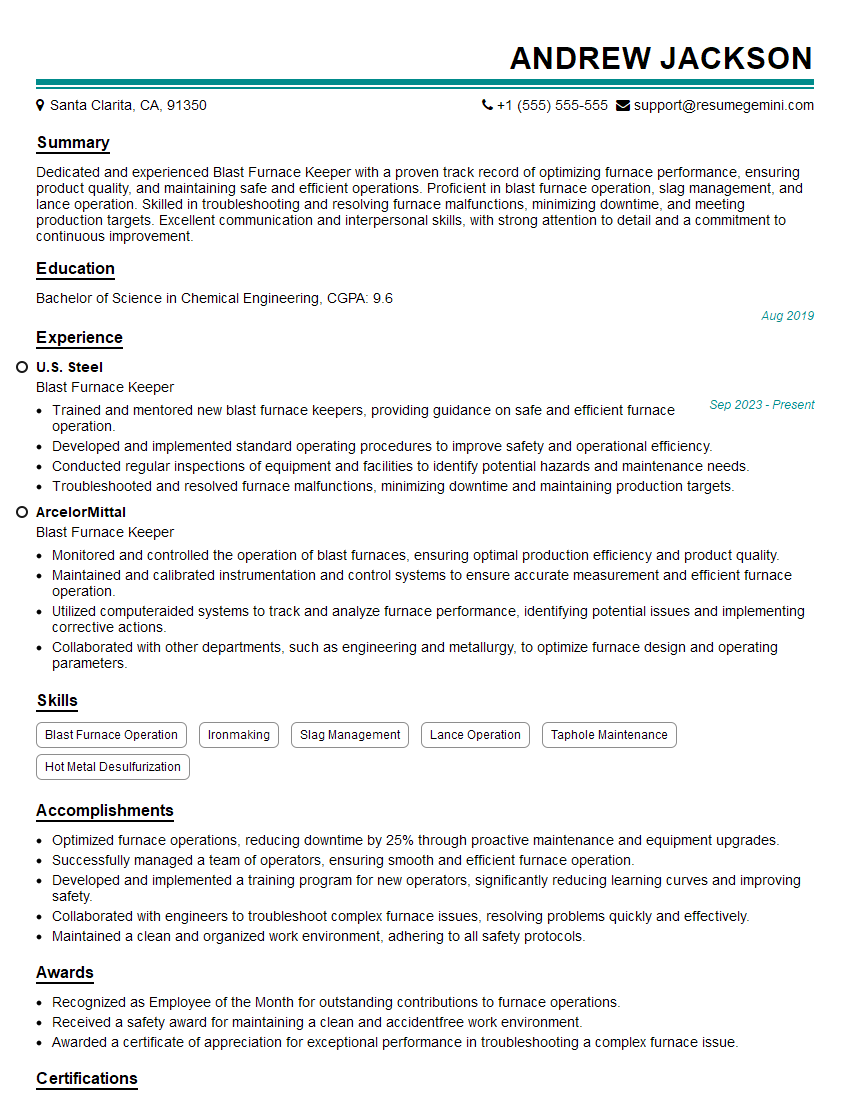

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Keeper

1. What are the key responsibilities of a Blast Furnace Keeper?

As a Blast Furnace Keeper, my primary responsibilities include:

- Monitoring and controlling the operation of the blast furnace to ensure optimal production and efficiency.

- Adjusting raw material inputs, such as iron ore, coke, and limestone, to maintain desired furnace conditions.

2. Describe the different types of raw materials used in a blast furnace and their functions.

- Iron Ore: Provides the iron content for the production of molten iron.

- Coke: Acts as a fuel and reducing agent, converting iron oxide to metallic iron.

- Limestone: Forms a slag that absorbs impurities from the molten iron, facilitating its removal.

- Fluorspar: Enhances slag fluidity and improves sulfur removal.

3. Explain the process of burdening a blast furnace.

Burdening involves charging the blast furnace with raw materials in a specific arrangement to achieve optimal performance:

- Iron ore, coke, and limestone are layered in the furnace in alternating layers.

- The burden is designed to allow for proper air flow and heat exchange.

- The distribution of materials helps create a stable furnace operation.

4. What are the common problems that can occur during blast furnace operation, and how do you address them?

- Scaffolding: Accumulation of molten material on furnace walls, which can be resolved by increasing blast temperature or adjusting raw material ratios.

- Slips: Sudden descent of the burden in the furnace, which can be prevented by optimizing burden distribution and controlling slag viscosity.

- Blast Failures: Interruptions in the air supply, which can be addressed by checking valves, pipelines, and the blower.

5. Describe the safety precautions and procedures that must be followed when operating a blast furnace.

- Wear appropriate protective gear, including heat-resistant clothing, gloves, and respiratory protection.

- Monitor gas levels and temperature to ensure a safe work environment.

- Follow established procedures for handling and storing raw materials.

- Adhere to lockout/tagout protocols during maintenance.

6. How do you calculate the coke rate in a blast furnace, and what factors influence it?

Coke rate is calculated as the weight of coke used per ton of hot metal produced.

- Influencing Factors: Ore quality, blast temperature, slag composition, and furnace efficiency.

- Lower coke rate: Indicates efficient furnace operation and reduced production costs.

7. Describe the role of the blast furnace in steelmaking, and how it contributes to the overall process.

- The blast furnace produces molten iron, which is the primary feedstock for steelmaking.

- High-quality molten iron with low impurities ensures efficient conversion to steel in subsequent processes.

- Stable blast furnace operation is crucial for maintaining a reliable supply of molten iron to the steelmaking facilities.

8. What are the environmental considerations associated with blast furnace operation, and how do you mitigate them?

- Air pollution from particulate matter, sulfur oxides, and nitrogen oxides.

- Mitigation Measures: Gas cleaning systems, fuel switching, and process optimization to reduce emissions.

- Water pollution from wastewater streams.

- Mitigation Measures: Wastewater treatment, recycling, and spill prevention.

9. Describe your experience in troubleshooting and resolving operational issues in a blast furnace environment.

Provide specific examples of problems you have encountered and the steps you took to resolve them:

- Example 1: Diagnosed and repaired a blast failure, restoring air flow and furnace stability.

- Example 2: Adjusted raw material ratios to address scaffolding and improve furnace efficiency.

10. How do you stay updated with advancements in blast furnace technology and best practices?

- Attend industry conferences and workshops.

- Subscribe to technical journals and publications.

- Participate in online forums and discussions.

- Engage with equipment manufacturers and technical experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Keeper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Keeper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Furnace Keepers are responsible for the operation and maintenance of blast furnaces, which are used to produce iron and steel. They monitor the furnace’s temperature, pressure, and other operating conditions, and make adjustments as needed to ensure efficient operation. They also perform routine maintenance and repairs on the furnace and its equipment.

1. Monitor and control blast furnace operations

Blast Furnace Keepers monitor and control the operation of the blast furnace, including the temperature, pressure, and flow of materials. They also make adjustments to the furnace’s settings to ensure that it is operating efficiently.

- Monitor the temperature of the blast furnace using thermocouples and other instruments.

- Control the pressure in the blast furnace by adjusting the flow of air and other gases.

- Control the flow of materials into and out of the blast furnace, including iron ore, coke, and limestone.

- Adjust the furnace’s settings to ensure that it is operating efficiently and producing high-quality iron.

2. Perform routine maintenance and repairs

Blast Furnace Keepers perform routine maintenance and repairs on the blast furnace and its equipment. They also troubleshoot and resolve any problems that may arise.

- Inspect the blast furnace and its equipment for wear and tear.

- Perform routine maintenance tasks, such as greasing bearings and replacing filters.

- Repair any problems that may arise with the blast furnace or its equipment.

- Troubleshoot any problems that may occur with the blast furnace or its equipment.

3. Ensure safety and environmental compliance

Blast Furnace Keepers are responsible for ensuring the safety of themselves and others, as well as the protection of the environment. They follow all safety procedures and regulations, and they take steps to minimize the environmental impact of the blast furnace’s operation.

- Follow all safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE).

- Take steps to minimize the environmental impact of the blast furnace’s operation.

- Report any safety or environmental concerns to their supervisor.

4. Communicate with other team members

Blast Furnace Keepers work with a team of other workers, including operators, maintenance technicians, and engineers. They communicate with each other to ensure that the blast furnace is operating safely and efficiently.

- Communicate with other team members to ensure that the blast furnace is operating safely and efficiently.

- Share information about the blast furnace’s operation with other team members.

- Resolve any conflicts or disagreements with other team members.

- Work with other team members to improve the efficiency of the blast furnace’s operation.

Interview Tips

Preparing for a job interview can be nerve-wracking, but by following these tips, you can increase your chances of success.

1. Research the company and the position

Take some time to research the company you’re applying to and the position you’re interested in. This will help you understand the company’s culture, values, and goals, and it will also help you answer questions about your qualifications and experience.

- Visit the company’s website and read about their history, mission, and values.

- Read job postings and descriptions carefully.

- Talk to people who work at the company, if possible.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions.

- Practice your answers out loud in front of a mirror or with a friend.

- Time yourself to make sure that your answers are concise.

3. Dress appropriately

First impressions matter, so make sure to dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture.

- Dress in business attire, even if the company has a casual dress code.

- Make sure your clothes are clean and pressed.

- Avoid wearing too much jewelry or makeup.

- Choose comfortable shoes that you can walk in easily.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. If you’re running late, call or email the interviewer to let them know.

- Plan your route in advance and allow extra time for traffic or other delays.

- If you’re running late, call or email the interviewer to let them know.

- Don’t be afraid to ask for directions if you get lost.

5. Be yourself

It’s important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine, and let your personality shine through.

- Be honest and genuine in your answers.

- Let your personality shine through.

- Don’t try to be someone you’re not.

- Be confident in your abilities and qualifications.

Next Step:

Now that you’re armed with the knowledge of Blast Furnace Keeper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blast Furnace Keeper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini