Feeling lost in a sea of interview questions? Landed that dream interview for Blast Furnace Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Blast Furnace Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

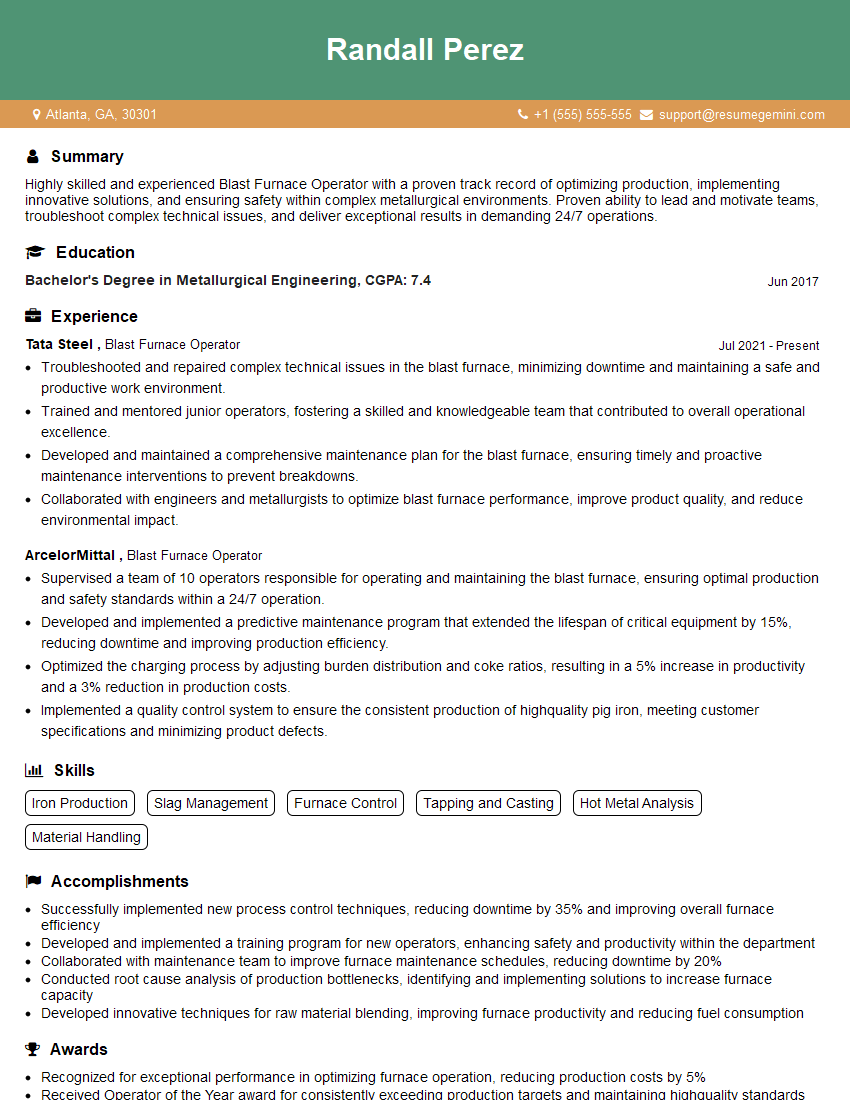

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Furnace Operator

1. Describe the key responsibilities and duties of a Blast Furnace Operator.

As a Blast Furnace Operator, my key responsibilities would include:

- Monitoring and controlling the blast furnace to ensure optimal production

- Adjusting inputs and operating parameters to maintain stable furnace conditions

- Monitoring and analyzing process data to identify potential issues and take corrective actions

- Ensuring compliance with safety and environmental regulations

- Working effectively with colleagues in a team environment

2. Explain the combustion reactions that occur within a blast furnace.

Within a blast furnace, several combustion reactions take place:

a. Coke Combustion

- 2C + O2 → 2CO

- CO + O2 → CO2

b. Iron Oxide Reduction

- Fe2O3 + CO → 2FeO + CO2

- FeO + CO → Fe + CO2

3. How do you manage slag formation in a blast furnace?

Slag management is crucial to prevent blockages and ensure smooth operation:

- Controlling the ratio of lime to silica in the burden

- Adjusting the temperature and flow rate of the slag

- Tapping the slag at regular intervals

- Monitoring slag composition to optimize its fluidity and viscosity

4. Describe the safety measures you follow when operating a blast furnace.

Safety is paramount:

- Wearing appropriate protective gear

- Following established operating procedures

- Regularly inspecting equipment and reporting any concerns

- Monitoring gas levels and adhering to safety protocols

- Undergoing regular training and refresher courses

5. How do you troubleshoot common issues encountered in blast furnace operations?

Troubleshooting is crucial for maintaining efficiency:

- Identifying the root cause of the issue

- Analyzing process data and making necessary adjustments

- Consulting with experienced operators or engineers

- Implementing corrective actions and monitoring their effectiveness

6. How do you optimize the efficiency of a blast furnace?

Optimization is key to maximize production:

- Maintaining stable furnace conditions

- Minimizing downtime and interruptions

- Monitoring and adjusting process parameters

- Implementing automation and control systems

7. Explain the principles of cast house operations in a blast furnace.

Cast house operations ensure proper iron and slag handling:

- Controlling the flow of molten iron and slag

- Operating casting machines and slag granulation systems

- Maintaining equipment and ensuring smooth operations

- Adhering to safety protocols and environmental regulations

8. Describe the maintenance procedures you perform on a blast furnace.

Regular maintenance is crucial for equipment longevity:

- Inspecting and cleaning equipment

- Lubricating moving parts

- Replacing worn or damaged components

- Conducting major overhauls as scheduled

9. How do you coordinate with other departments within the plant?

Effective coordination is essential for overall plant operations:

- Communicating with raw materials preparation for burden management

- Coordinating with maintenance for equipment upkeep

- Exchanging information with the quality control department

- Collaborating with logistics for product transportation

10. Describe your experience with process control and automation in blast furnace operations.

Process control and automation enhance efficiency:

- Utilizing sensors and instruments for data collection

- Implementing control algorithms to optimize furnace parameters

- Monitoring and analyzing process data for real-time adjustments

- Troubleshooting and maintaining automation systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blast Furnace Operator is responsible for the safe and efficient operation of a blast furnace, which is a critical piece of equipment in the production of iron and steel. Key job responsibilities typically include:

1. Furnace Operation

Ensuring the smooth and efficient operation of the blast furnace, including charging the furnace with raw materials, regulating the flow of air and fuel, and monitoring the temperature and pressure of the furnace.

- Charging the blast furnace with iron ore, coke, and limestone

- Controlling the temperature and pressure inside the blast furnace

- Monitoring the flow of air and fuel into the blast furnace

2. Equipment Maintenance

Performing routine maintenance and repairs on the blast furnace and its associated equipment, including pumps, valves, and instrumentation.

- Inspecting and maintaining the blast furnace and its associated equipment

- Performing minor repairs on the blast furnace and its associated equipment

- Requesting major repairs to the blast furnace and its associated equipment

3. Process Monitoring

Monitoring the blast furnace process and making adjustments as needed to ensure that the furnace is operating safely and efficiently, including monitoring the quality of the molten iron produced.

- Monitoring the quality of the molten iron produced by the blast furnace

- Making adjustments to the blast furnace process as needed

- Reporting any problems with the blast furnace process to superiors

4. Safety Compliance

Adhering to all safety regulations and procedures related to the operation of the blast furnace, including wearing appropriate personal protective equipment and following established lockout/tagout procedures.

- Wearing appropriate personal protective equipment

- Following established lockout/tagout procedures

- Reporting any safety hazards to superiors

Interview Tips

Preparing for an interview for a Blast Furnace Operator position requires a combination of technical knowledge and interview skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Understanding the company’s history, values, and current projects will demonstrate your interest and enthusiasm for the role. Additionally, researching the specific responsibilities of the Blast Furnace Operator position will help you tailor your answers to the interviewer’s questions.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining blast furnaces or similar industrial equipment. Quantify your accomplishments using specific metrics and provide examples that showcase your technical skills and problem-solving abilities.

3. Demonstrate Safety Knowledge

Safety is paramount in the operation of blast furnaces. Familiarize yourself with industry safety regulations and best practices, and be prepared to discuss your understanding of lockout/tagout procedures and emergency protocols.

4. Practice Troubleshooting Scenarios

Blast Furnace Operators often encounter unexpected situations. Prepare for the interview by practicing troubleshooting scenarios that demonstrate your ability to analyze problems, identify root causes, and develop effective solutions.

5. Be Prepared for Technical Questions

Expect technical questions related to the blast furnace process, equipment maintenance, and process monitoring. Review basic principles of metallurgy, furnace design, and instrumentation to confidently answer these questions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blast Furnace Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!