Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blast Hole Driller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

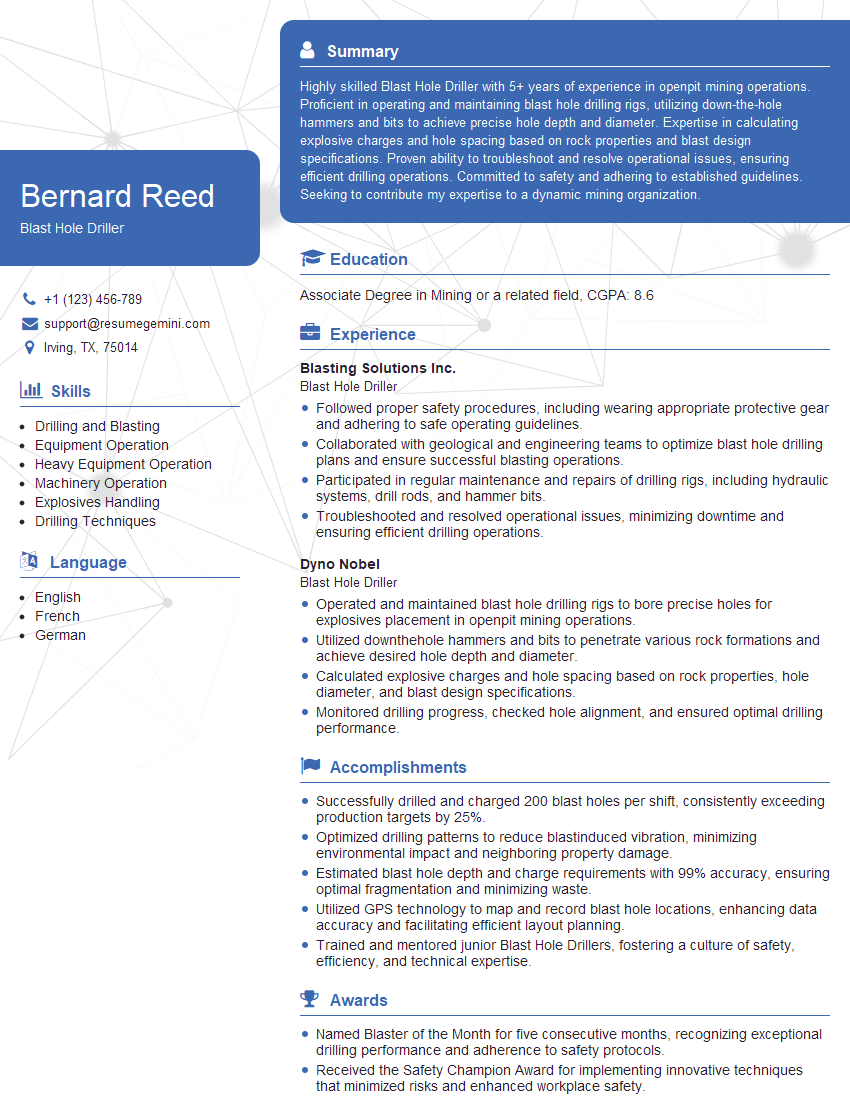

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Hole Driller

1. How do you ensure the stability of the blast hole during drilling?

To ensure the stability of the blast hole during drilling, I adhere to the following practices:

- Proper selection and maintenance of drilling equipment, including bits, rods, and casing

- Careful monitoring of drilling parameters such as rotation speed, feed rate, and flushing pressure

- Use of stabilizers and centralizers to keep the drill string aligned

- Attention to ground conditions and adjustment of drilling techniques as necessary

2. Describe your experience in operating different types of blast hole drills.

Rotary Drills

- Successfully operated various models of rotary drills, including top-head and down-the-hole

- Expertise in drilling vertical, inclined, and horizontal holes

Percussive Drills

- Proficient in using both handheld and truck-mounted percussive drills

- Experience in drilling in challenging ground conditions, such as hard rock and fractured formations

3. How do you handle and maintain drill bits to optimize their performance?

- Regular inspection of bits for wear and damage

- Selection of appropriate bit type and size based on ground conditions

- Proper lubrication and cooling of bits to extend their lifespan

- Sharpening and reconditioning bits to maintain optimal cutting efficiency

4. Describe your knowledge of explosives and their safe handling.

I possess a comprehensive understanding of explosives and their safe handling, including:

- Types and properties of explosives used in blasting

- Storage and transportation regulations

- Safety protocols for handling, loading, and detonating explosives

- Proper use of blasting accessories such as detonators and safety fuse

5. How do you assess ground conditions and select appropriate drilling parameters?

- Conduct thorough site surveys to determine ground characteristics, such as rock type, hardness, and presence of water

- Consult with geologists and engineers to obtain accurate information about the subsurface

- Adjust drilling parameters, such as rotation speed, feed rate, and flushing pressure, based on the ground conditions

6. Explain the importance of proper flushing during drilling and how you ensure it is done effectively.

- Flushing removes cuttings from the hole, reducing friction and bit wear

- It cools the drill bit and prevents overheating

- Ensuring effective flushing involves using an appropriate flushing medium, such as water or compressed air, and maintaining sufficient flow rate

7. Describe your experience in managing and maintaining a drilling site, including safety and environmental considerations.

- Established and maintained a safe work environment by implementing safety protocols and conducting regular risk assessments

- Ensured compliance with environmental regulations, including proper waste disposal and spill prevention

- Kept the site organized and clean to minimize hazards and improve efficiency

8. How do you troubleshoot and resolve common drilling problems, such as stuck rods or bit breakage?

- Use a systematic approach to identify the root cause of the problem

- Apply appropriate troubleshooting techniques, such as adjusting drilling parameters, using retrieval tools, or changing bits

- Analyze the problem and take steps to prevent it from recurring

9. Describe your understanding of the different types of drill hole patterns and how they affect blasting results.

I understand the various drill hole patterns commonly used in blasting, including:

- Square patterns: Provide uniform distribution of explosives and result in good fragmentation

- Staggered patterns: Allow for better confinement and reduce ground vibration

- Triangle patterns: Suitable for difficult ground conditions and improve fragmentation

10. Explain your knowledge of blasting techniques and how you apply them to achieve optimal results.

- Well-versed in different blasting techniques, such as delay blasting and sequential blasting

- Determine the appropriate blasting parameters, such as charge size and timing, based on the desired fragmentation and ground conditions

- Monitor and evaluate blasting results to continuously improve practices and ensure safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Hole Driller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Hole Driller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Hole Drillers are responsible for operating and maintaining blast hole drilling equipment used in mining, construction, and quarrying operations. Their primary duty is to drill holes into rock or other hard materials to prepare for blasting operations.

1. Drilling Operations

Operate and maintain blast hole drilling equipment, such as rotary or down-the-hole drills.

- Set up and position the drilling equipment at designated locations.

- Select and install appropriate drill bits and rods.

- Drill holes to specified depths and diameters.

- Monitor drilling progress and adjust settings as needed.

2. Equipment Maintenance

Perform routine maintenance and repairs on drilling equipment.

- Lubricate and adjust moving parts.

- Replace worn or damaged components.

- Troubleshoot equipment malfunctions and resolve issues.

- Ensure equipment is operating safely and efficiently.

3. Safety and Regulations

Adhere to safety regulations and protocols.

- Wear appropriate personal protective equipment (PPE).

- Follow safe operating procedures.

- Maintain a clean and organized work area.

- Report any hazards or unsafe conditions.

4. Communication and Teamwork

Work effectively as part of a team or with other contractors.

- Communicate with supervisors, engineers, and other workers.

- Collaborate on planning and executing drilling operations.

- Provide guidance and support to less experienced colleagues.

Interview Tips

To prepare for a Blast Hole Driller interview, it’s crucial to have a thorough understanding of the key job responsibilities and industry-specific knowledge. Here are some tips to help you ace the interview:

1. Research the Company and Position

Demonstrate your interest in the company and specific role by researching their history, operations, and the responsibilities of a Blast Hole Driller.

- Visit the company’s website and social media profiles.

- Read industry publications and articles related to blast hole drilling.

- Network with professionals in the field to gain insights.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experience that directly align with the key job responsibilities. Use specific examples to demonstrate your proficiency.

- Discuss your experience operating and maintaining blast hole drilling equipment.

- Provide examples of how you ensured safety and adherence to regulations.

- Highlight any teamwork or communication skills that are relevant to the role.

3. Prepare for Technical Questions

Expect technical questions related to blast hole drilling equipment, drilling techniques, and safety procedures.

- Review different types of drilling rigs and their applications.

- Be familiar with drilling parameters, such as bit selection, rotation speed, and feed rate.

- Study safety regulations and industry best practices for blast hole drilling.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance.

- Tell me about yourself and your experience.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- How do you handle working in a team environment?

- What are your salary expectations?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blast Hole Driller interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.