Are you gearing up for an interview for a Blast Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blast Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

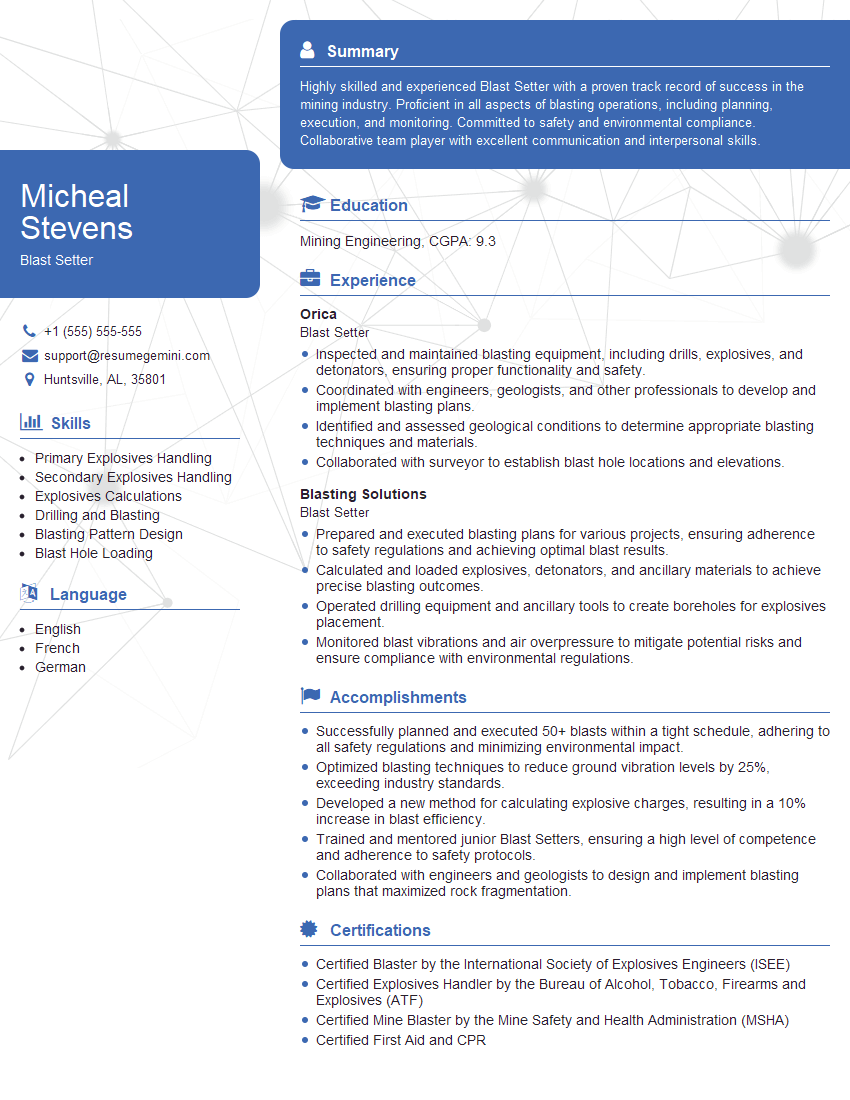

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blast Setter

1. What are the key responsibilities of a Blast Setter?

- Prepare blasting area by clearing vegetation, removing debris, and setting up safety barriers.

- Load and position explosives according to specified pattern and sequence.

- Connect explosives to detonators and ignition system.

- Monitor blasting site during detonation and ensure safety of personnel and equipment.

- Inspect blasting site after detonation to ensure complete detonation and remove any unexploded explosives.

2. How do you determine the appropriate type and quantity of explosives for a given blasting project?

Factors considered:

- Type of rock or material being blasted

- Size and shape of the area to be blasted

- Depth of the blast

- Proximity of structures and other potential hazards

Calculation methods:

- Empirical formulas

- Computer modeling

- Consultation with explosives manufacturers

3. What safety precautions do you take when handling and using explosives?

- Wear appropriate personal protective equipment (PPE), including hard hat, safety glasses, earplugs, and gloves.

- Follow all established safety procedures and regulations.

- Store explosives securely in a designated magazine.

- Transport explosives safely and securely in accordance with regulations.

- Never smoke or use open flames near explosives.

- Notify authorities and evacuate the area in case of any incident or emergency.

4. How do you assess the stability of a rock face or structure before blasting?

- Visual inspection for cracks, loose rocks, or other signs of instability.

- Geotechnical surveys to determine rock properties and structure.

- Monitoring system to track movement or deformation.

- Consultation with engineers or geologists for recommendations.

5. What methods do you use to control ground vibrations and airblast from blasting operations?

- Proper blast design to minimize vibration and airblast levels.

- Use of vibration mats or buffers to absorb vibrations.

- Directional blasting to minimize airblast towards sensitive areas.

- Monitoring system to track vibration and airblast levels.

- Communication with nearby residents and businesses to inform them about blasting schedule and precautions.

6. How do you manage environmental impacts from blasting operations?

- Obtain necessary environmental permits and comply with regulations.

- Minimize dust and noise pollution through proper blasting techniques and dust suppression measures.

- Protect water sources from contamination by explosives or blasting debris.

- Restore blasting site to its original condition or better after operations.

- Monitor environmental impacts and make adjustments as necessary.

7. What are the different types of blasting patterns used, and when are they most appropriate?

- Grid pattern: Regular rows and columns, used for general excavation and mass blasting.

- Contour pattern: Follows contours of the rock face, used for bench blasting in quarries.

- V-cut pattern: Creates a V-shaped cut, used for trenching or underwater blasting.

- Skewed pattern: Holes are drilled at an angle, used to reduce ground vibrations and airblast.

- Smooth blasting pattern: Holes are closely spaced, used to create a smooth surface after blasting.

8. How do you calculate the firing sequence for a multiple-hole blast?

- Determine the desired delay between each hole.

- Calculate the total time required for the entire blast.

- Assign firing delays to each hole in a sequence that ensures proper fragmentation and minimizes ground vibration.

- Use electronic detonators or delay timing devices to control the firing sequence.

9. What troubleshooting steps do you take if a blast does not detonate properly?

- Check the blasting machine and electrical connections.

- Inspect the detonators and ensure they are properly connected.

- Verify the firing sequence and blast design.

- Examine the rock face for any obstructions or unusual conditions.

- Contact the explosives manufacturer or a qualified expert for assistance.

10. Describe your experience in using specialized blasting techniques, such as underwater blasting or controlled blasting.

- Underwater blasting: Explain the use of waterproof explosives, special equipment, and safety measures.

- Controlled blasting: Describe techniques for minimizing damage to nearby structures or sensitive areas, such as using shaped charges or air decks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blast Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blast Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blast Setters are responsible for preparing and setting up explosives for blasting operations in mining, construction, and demolition projects. They ensure that the blasting process is carried out safely and efficiently, minimizing risks and potential damage.

1. Preparing Explosives and Equipment

Determines the type and quantity of explosives required for the blast based on project specifications and geological conditions.

- Inspects and prepares explosives, detonators, and other blasting materials.

- Assembles and connects electrical circuits and detonators to initiate the blasts.

2. Site Preparation and Layout

Conducts site surveys and develops blasting plans, including determining the location, depth, and spacing of boreholes for explosives.

- Drills boreholes using specialized equipment and techniques.

- Loads explosives into boreholes and tamp them securely.

3. Blasting and Monitoring

Initiates the blasts according to approved plans and safety protocols.

- Monitors the blast area to ensure safety and minimize damage.

- Records and documents blasting data for analysis and future reference.

4. Post-Blast Inspection and Cleanup

Conducts post-blast inspections to assess the results, identify potential hazards, and plan for cleanup.

- Inspects the blast area for unexploded explosives or debris.

- Reports any incidents, accidents, or concerns to supervisors.

Interview Tips

Preparing for a Blast Setter interview requires both technical proficiency and a commitment to safety. Here are some tips to help you ace the interview:

1. Highlight Experience and Qualifications

Emphasize your relevant experience in blasting operations, including the types of projects and explosives you have worked with.

- Quantify your experience with specific numbers and accomplishments.

- Provide examples of successful blasting projects where you demonstrated expertise and safety consciousness.

2. Demonstrate Safety Knowledge

Blast Setters must prioritize safety in every aspect of their work. Highlight your understanding of blasting safety regulations and protocols.

- Discuss your experience in following safety guidelines, conducting risk assessments, and managing potential hazards.

- Mention any certifications or training programs you have completed related to blasting safety.

3. Showcase Technical Skills

Employers seek candidates with a strong grasp of blasting techniques, explosives, and equipment. Showcase your technical abilities and knowledge.

- Describe your proficiency in using different types of drilling and blasting equipment.

- Demonstrate your understanding of explosive properties, blasting design principles, and detonation sequencing.

4. Prepare for Common Interview Questions

Anticipate and prepare answers to common interview questions related to blasting operations, safety protocols, and your approach to the job.

- Practice answering questions about your experience in handling different types of explosives.

- Prepare to discuss your safety mindset and how you prioritize risk assessment and hazard management.

Next Step:

Now that you’re armed with the knowledge of Blast Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blast Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini