Are you gearing up for a career in Blasting Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Blasting Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

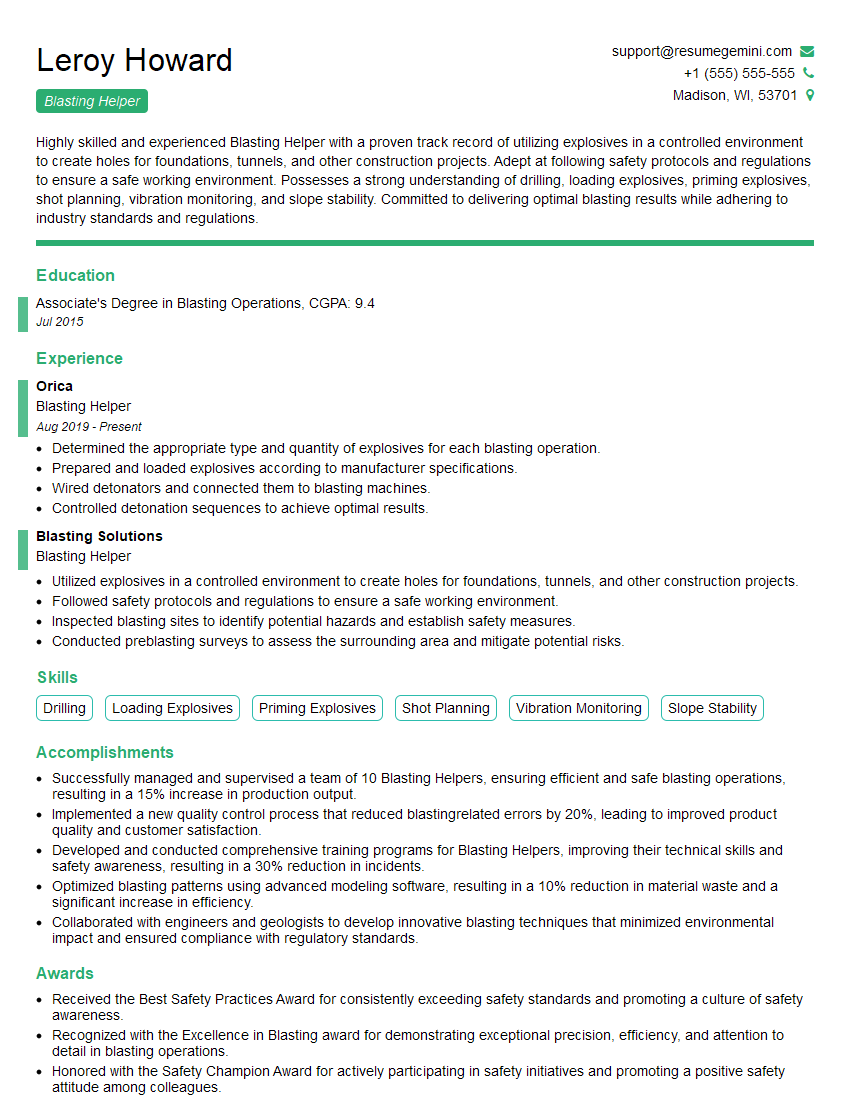

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blasting Helper

1. What are the different types of explosives used in blasting operations, and how do they differ in their characteristics?

There are three main types of explosives used in blasting operations:

- Dynamite – Dynamite is a high explosive that is made from nitroglycerin, wood pulp, and other materials. It is a powerful explosive that is used in a variety of applications, including mining, quarrying, and construction.

- Anfo – Anfo is a low explosive that is made from ammonium nitrate and fuel oil. It is a less powerful explosive than dynamite, but it is also less expensive. Anfo is used in a variety of applications, including mining, quarrying, and construction.

- Slurry – Slurry is a type of explosive that is made from a mixture of ammonium nitrate, water, and other materials. It is a powerful explosive that is used in a variety of applications, including mining, quarrying, and construction.

2. How do you calculate the amount of explosive needed for a given blast?

Factors to Consider

- The type of explosive being used

- The size of the area being blasted

- The type of rock or soil being blasted

- The desired results of the blast

Calculation Method

- Use empirical formulas or software programs that take into account the above factors.

- Consult with experienced blasters or engineers for guidance.

3. How do you prepare a blasting site?

- Conduct a thorough site survey to identify potential hazards and determine the best blasting plan.

- Clear the area of any obstacles, such as trees, rocks, or debris.

- Establish a safe perimeter around the blast area.

- Prepare the blast holes by drilling or excavating them to the desired depth and diameter.

4. What are the different methods of initiating a blast, and which method is most appropriate for different situations?

- Safety fuse – Safety fuse is a type of slow-burning fuse that is used to initiate a blast. It is a simple and inexpensive method of initiation, but it is also less reliable than other methods.

- Electric detonators – Electric detonators are a type of electrical device that is used to initiate a blast. They are more reliable than safety fuse, but they are also more expensive.

- Non-electric detonators – Non-electric detonators are a type of electronic device that is used to initiate a blast. They are the most reliable and safest method of initiation, but they are also the most expensive.

Method Selection

- Consider factors such as environmental conditions, safety requirements, and cost.

- Follow industry standards and regulations for the specific blasting operation.

5. How do you ensure the safety of personnel and the surrounding environment during a blasting operation?

- Establish clear safety protocols and ensure all personnel are aware of them.

- Conduct thorough site inspections and risk assessments before and after blasting.

- Use proper blasting techniques and equipment to minimize the risk of accidents.

- Monitor the blast area for potential hazards, such as flyrock or ground vibrations.

- Implement measures to control noise, dust, and other environmental impacts.

6. What are the different types of blasting patterns, and when is each type most appropriate?

- Single-row pattern – A single-row pattern is the simplest type of blasting pattern. It consists of a single row of holes drilled in a straight line.

- Multiple-row pattern – A multiple-row pattern consists of two or more rows of holes drilled in a parallel arrangement.

- Staggered pattern – A staggered pattern is a variation of the multiple-row pattern in which the holes in each row are offset from the holes in the adjacent rows.

Pattern Selection

- Factors to consider: rock type, desired fragmentation size, and blasting conditions.

- Single-row patterns are suitable for small-scale blasts in soft rock.

- Multiple-row and staggered patterns are used for larger blasts or in harder rock.

7. How do you measure the results of a blast, and how do you use this information to improve future blasts?

Measurement Techniques

- Fragmentation analysis

- Vibration monitoring

- Ground movement monitoring

Data Analysis and Improvement

- Analyze the data to determine the effectiveness of the blast.

- Identify areas for improvement, such as adjusting the blasting pattern, explosive type, or initiation method.

- Implement changes to improve the results of future blasts.

8. What are the common problems that can occur during blasting operations, and how do you troubleshoot them?

- Misfires – A misfire occurs when a blast does not detonate as intended.

- Flyrock – Flyrock is a term used to describe rock fragments that are ejected from the blast area.

- Ground vibrations – Ground vibrations are a type of seismic wave that is generated by a blast.

- Noise – Blasting operations can generate a significant amount of noise.

- Dust – Blasting operations can generate a significant amount of dust.

Troubleshooting Methods

- Investigate the cause of the problem and implement corrective actions.

- Follow established safety protocols and regulations to minimize the risk of accidents.

- Use proper blasting techniques and equipment to mitigate potential problems.

9. What are the ethical responsibilities of a blasting helper?

- Prioritize safety and follow all safety regulations.

- Handle explosives responsibly and securely.

- Respect the environment and minimize the impact of blasting operations.

- Maintain confidentiality and protect sensitive information.

- Act with integrity and professionalism at all times.

10. How do you stay up-to-date on the latest developments in blasting technology and best practices?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Seek guidance from experienced blasters and engineers.

- Complete continuing education courses or certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blasting Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blasting Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blasting Helpers play a critical role in mining, construction, and other industries that utilize explosives. Their key responsibilities include:

1. Prepare and Load Explosives

Assist in assembling and loading explosives into boreholes or prepared sites as directed by the Blaster.

- Ensure proper placement and spacing of explosives.

- Handle and store explosives safely and responsibly.

2. Connect and Prime Explosives

Assist in connecting explosives electrically or through other methods and prime them for detonation.

- Verify the continuity of electrical circuits used for blasting.

- Ensure proper priming procedures are followed.

3. Assist in Blasting Operations

Provide support during blasting operations, including:

- Clearing the blast area and ensuring safety protocols.

- Participating in the inspection of blast sites.

- Assisting with the clean-up of blast debris.

4. Maintain Equipment

Maintain and inspect blasting equipment, including explosives, detonators, and related accessories.

- Report any defects or malfunctions promptly.

- Ensure equipment is in good working condition.

Interview Tips

To prepare effectively for a Blasting Helper interview, consider the following tips:

1. Research the Company and Industry

Gather information on the company’s operations, its safety record, and its role within the industry. This will demonstrate your interest and understanding.

- Check the company’s website, industry publications, and news articles.

- Attend industry events or webinars to network and learn more about the sector.

2. Highlight Relevant Skills and Experience

Emphasize your experience in handling explosives, maintaining equipment, and following safety protocols. Provide specific examples of your work.

- Quantify your accomplishments whenever possible.

- Be prepared to discuss your understanding of blasting techniques and regulations.

3. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and why you’re interested in the role. Consider using the STAR method (Situation, Task, Action, Result) to provide structured and compelling answers.

- Examples include questions on safety procedures, equipment maintenance, and your approach to working in a team.

- Practice your answers aloud to improve your delivery and confidence.

4. Showcase Your Safety Consciousness

Blasting operations require a strong commitment to safety. Highlight your adherence to safety regulations, your awareness of potential hazards, and your ability to work safely in a hazardous environment.

- Discuss your understanding of the importance of proper handling and storage of explosives.

- Explain your experience in following safety checklists and reporting any concerns.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Blasting Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.