Are you gearing up for a career in Blasting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Blasting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

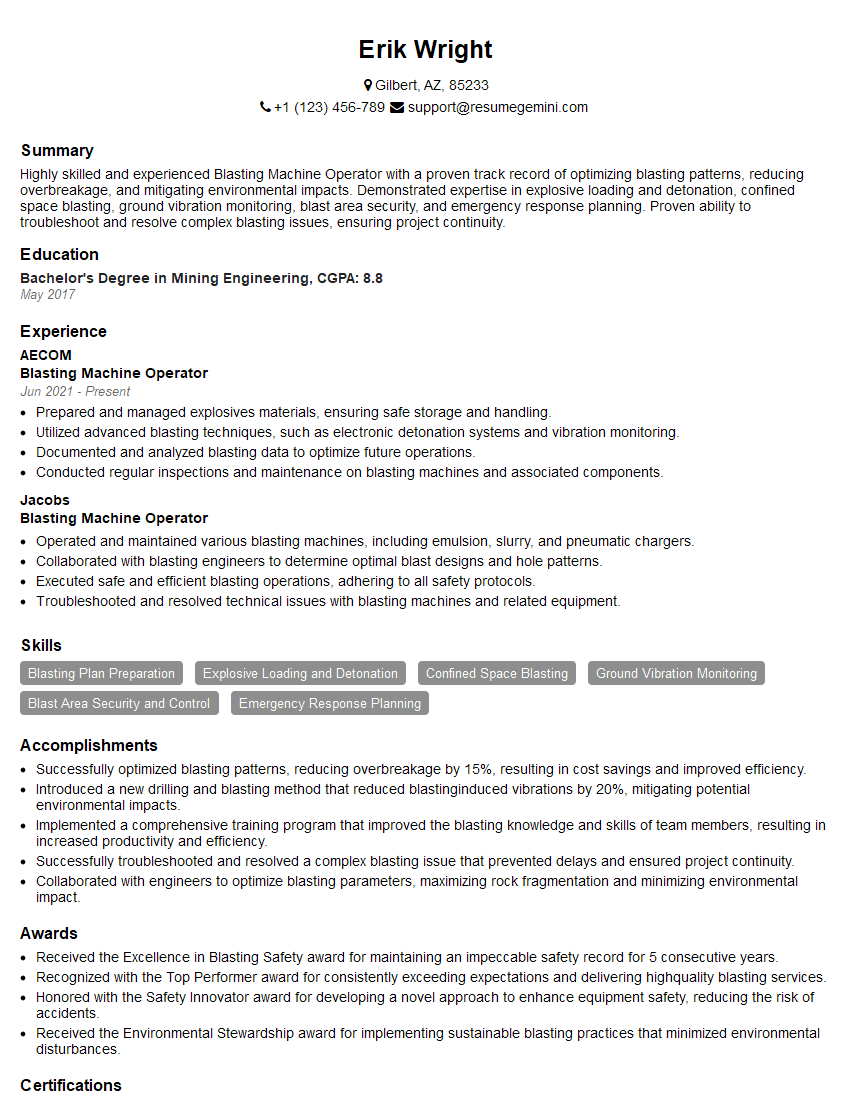

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blasting Machine Operator

1. How do you ensure accuracy and precision when preparing explosives for blasting?

- Follow stringent procedures and utilize calibrated equipment for measurements.

- Double-check calculations to minimize errors in explosive quantities.

- Inspect explosive materials thoroughly for any defects or inconsistencies.

- Adhere to strict guidelines for handling, storage, and transportation of explosives.

2. What are some key electrical considerations when operating blasting machines?

Grounding

- Properly ground blasting machines to prevent static discharge and ensure safe operation.

- Check grounding connections visually and with a continuity tester prior to use.

Circuit Continuity

- Verify circuit continuity using a blasting galvanometer or continuity tester.

- Ensure that all connections are secure and free of any breaks or loose wires.

3. How do you handle different types of explosives, such as ammonium nitrate fuel oil (ANFO) and dynamite?

- Familiarize myself with the specific properties and safety requirements of each explosive.

- Store and handle explosives according to industry standards and manufacturer’s guidelines.

- Follow proper mixing procedures for ANFO, ensuring precise ratios and thorough blending.

- Understand the different detonation characteristics of dynamite and handle it with utmost care.

4. What safety precautions do you take when working with detonators?

- Handle detonators with extreme caution, avoiding any impact or friction.

- Never carry detonators loose in pockets or toolboxes.

- Store detonators in designated, secure locations, protected from moisture and temperature extremes.

- Follow established procedures for transporting detonators and ensure proper disposal methods.

5. Explain the importance of hole spacing and timing in blasting operations.

- Hole spacing influences the fragmentation and movement of rock in the blast.

- Proper hole spacing optimizes the distribution of explosive energy, reducing ground vibrations and unwanted damage.

- Timing sequences control the timing of detonations, ensuring the desired result and reducing noise and vibration.

6. What factors should be considered when selecting the right type of blasting machine?

- Evaluate the number of holes to be fired simultaneously and the required voltage.

- Consider the specific electrical characteristics of the detonators being used.

- Choose a blasting machine that meets safety and regulatory requirements.

7. How do you troubleshoot common problems with blasting machines, such as misfires?

- Check continuity of the blasting circuit, including connections and wires.

- Inspect detonators for any visible damage or defects.

- Verify that the blasting machine is functioning properly using a continuity tester.

- Ensure that the correct blasting caps are being used for the specific machine and voltage.

8. Describe the steps involved in conducting a pre-blast survey and what information is typically collected.

- Inspect the blast site for any potential hazards or risks.

- Map the area, including structures, utilities, and natural features.

- Collect information on ground conditions, rock properties, and blasting history.

- Identify any sensitive receptors or areas that require special protection.

9. How do you calculate the safe distance for blasting operations?

- Consider factors such as the explosive weight, charge type, ground conditions, and surrounding environment.

- Use established formulas or industry guidelines to determine the minimum safe distance for flyrock and airblast.

- Establish clear exclusion zones and warning systems to ensure public safety.

10. What procedures do you follow to ensure environmental compliance during blasting operations?

- Obtain necessary permits and adhere to regulatory requirements.

- Implement measures to minimize noise, dust, and vibration levels.

- Conduct environmental monitoring to assess potential impacts and take corrective actions if necessary.

- Restore the blast site to a safe and environmentally sound condition.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blasting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blasting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blasting machine operators are responsible for the safe and efficient operation of blasting machines in order to break rock or other materials. They work according to plans and specifications, and use a knowledge of explosives and their effects to safely operate and maintain the blasting machine. Some of their most common job responsibilities include:

1. Prepare and Install Explosives

Blasting machine operators begin by preparing the explosives that will be used in the blast. This includes measuring the explosives and combining them with other materials, such as sand or water, to create a slurry or paste. They then load the blasting agent into the blasting machine and position it in the desired location.

2. Operate Blasting Machine

Once the explosives are prepared and installed, the blasting machine operator carefully follows the specified sequence and timing to detonate the explosives. This is usually done by sending an electric current through a detonator, which triggers the explosion.

3. Monitor and Control Explosions

After the machine is activated, blasting machine operators must monitor and control the explosions to ensure that they occur as planned. They do this by observing the blast area and listening for any unusual sounds or vibrations. If necessary, they can adjust the timing or sequence of the explosions to achieve the desired results.

4. Maintain Equipment

In addition to operating blasting machines, these professionals are also responsible for maintaining them in good working order. This includes inspecting the machines, cleaning them, and replacing any worn or damaged parts. They must be able to identify and correct any problems with the equipment, and they must know how to safely handle and store explosives.

5. Follow Safety Regulations

Following all safety regulations is extremely important when working as a blasting machine operator. This includes wearing the appropriate protective gear, following the proper procedures for handling explosives, and ensuring that the blast area is clear of people and animals before detonating explosives.

Interview Tips

To ace an interview for a blasting machine operator position, candidates should be prepared to discuss their experience and knowledge in the following areas:

1. Knowledge of Explosives

Interviewers will want to know that the candidate has a thorough understanding of the different types of explosives and their uses. They should be able to explain the safe storage and handling of explosives, and they should be familiar with the regulations governing the use of explosives. Here are some questions which the interviewers can ask:

- What are the different types of explosives used in blasting operations?

- How are explosives safely stored and handled?

- What are the regulations governing the use of explosives?

2. Experience Operating Blasting Machines

Candidates should be prepared to discuss their experience operating blasting machines. This includes describing the different types of machines they have operated, the types of projects they have worked on, and the safety measures they have followed. The interviewers can ask:

- What types of blasting machines have you operated?

- What types of projects have you worked on?

- What safety measures do you follow when operating blasting machines?

3. Knowledge of Safety Regulations

Interviewers will want to know that the candidate has a thorough understanding of safety regulations governing the use of explosives. This includes the regulations set forth by OSHA and the Bureau of Mines. Candidates should be able to explain how these regulations apply to the operation of blasting machines. Here are some questions which the interviewers can ask:

- What are the OSHA and Bureau of Mines regulations governing the use of explosives?

- How do these regulations apply to the operation of blasting machines?

- What are the consequences of violating safety regulations?

4. Physical Fitness

Blasting machine operators must be in good physical condition. They must be able to lift heavy objects, climb ladders, and work in a variety of weather conditions. Interviewers may ask:

- What is your level of physical fitness?

- Can you lift heavy objects?

- Can you climb ladders?

- Can you work in a variety of weather conditions?

5. Attention to Detail

Blasting machine operators must have excellent attention to detail. They must be able to follow instructions carefully and ensure that all safety regulations are followed. Interviewers will ask:

- Do you have excellent attention to detail?

- Can you follow instructions carefully?

- Can you ensure that all safety regulations are followed?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blasting Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blasting Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.