Are you gearing up for an interview for a Blasting Production Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blasting Production Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

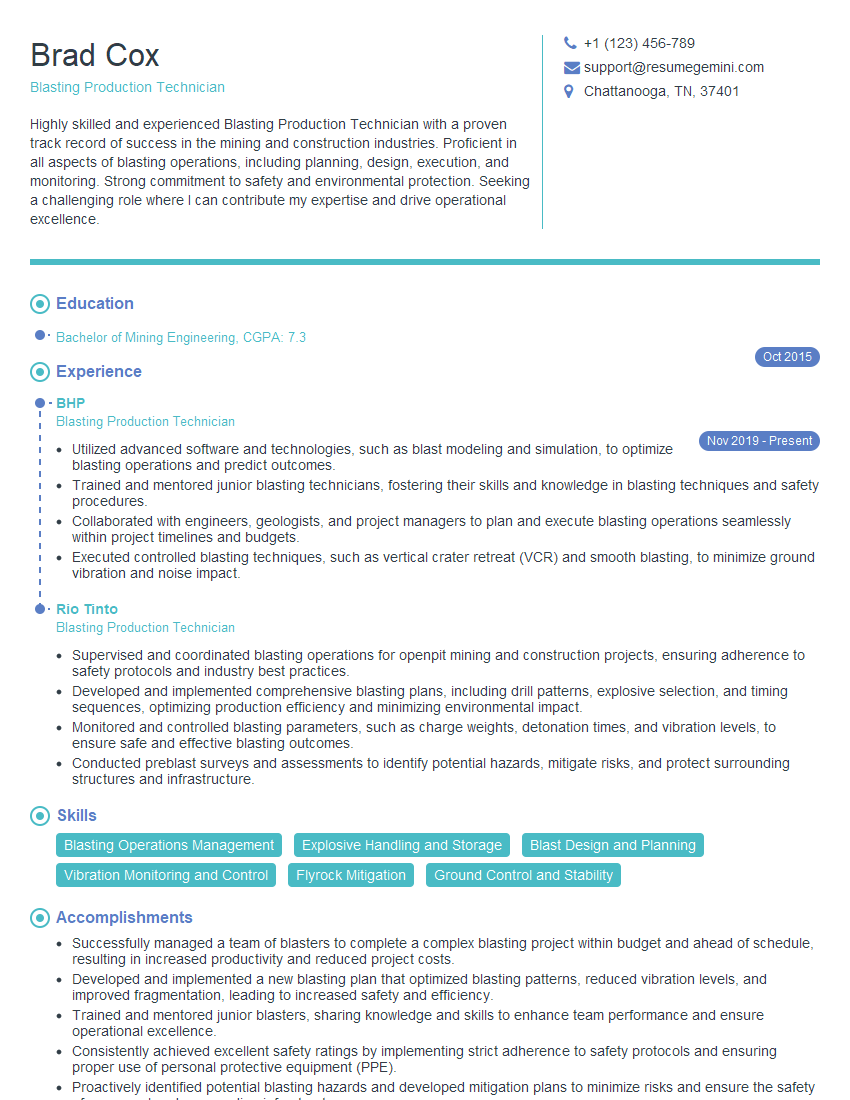

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blasting Production Technician

1. Explain the key responsibilities and tasks of a Blasting Production Technician?

As a Blasting Production Technician, my primary responsibilities revolve around the safe, efficient, and effective planning, execution, and monitoring of blasting operations within a mining or quarry environment.

- Conduct comprehensive site surveys and assessments to determine optimal blasting patterns, hole depths, and explosive charges.

- Prepare and load explosives based on approved designs, ensuring strict adherence to safety protocols and regulatory requirements.

- Operate and maintain blasting equipment, including drilling rigs, charging trucks, and detonators, ensuring proper functionality and calibration.

- Monitor blasting operations closely, observing rock movement and explosive performance to ensure adherence to plans and identify any potential hazards.

- Evaluate blasting results, analyze data, and make necessary adjustments to improve efficiency, safety, and environmental impact.

- Maintain accurate records and documentation of all blasting activities, ensuring compliance with industry standards and regulations.

2. Describe the types of explosives commonly used in blasting operations and their respective applications?

High Explosives

- Dynamite: Used for general blasting applications, including rock excavation and demolition.

- ANFO (Ammonium Nitrate and Fuel Oil): A cost-effective and versatile explosive used in large-scale mining operations.

- Emulsions: Water-in-oil or oil-in-water emulsions that provide controlled detonation velocities and reduced environmental impact.

Low Explosives

- Black Powder: A slow-burning explosive used for blasting in confined spaces and for creating special effects in entertainment.

- Fuse: A cord or tube filled with explosive used to initiate detonation in other explosives.

- Detonators: Small, highly sensitive devices used to initiate the detonation of high explosives.

3. Explain the factors that influence the design of a blasting pattern?

Blasting pattern design is crucial for ensuring safety, efficiency, and optimal rock fragmentation. Factors that influence the design include:

- Rock characteristics, such as hardness, density, and jointing.

- Desired fragmentation size and distribution.

- Environmental conditions, including temperature, humidity, and wind speed.

- Blasting equipment capabilities.

- Safety considerations, including proximity to structures, personnel, and sensitive areas.

- Regulatory requirements and industry best practices.

4. What are the different methods of initiating a blast?

There are several methods used to initiate a blast, including:

- Electric Detonators: Electrical signals are sent through wires to detonate the explosives.

- Non-Electric Detonators: Shock tubes or radio signals are used to initiate the detonation.

- Pyrotechnic Fuses: A slow-burning fuse ignites the explosives in a sequential order.

- Detonating Cord: A flexible, explosive-filled cord is used to initiate multiple charges simultaneously.

5. Describe the safety protocols and regulations that must be followed during blasting operations?

Strict safety protocols and regulations are paramount in blasting operations to prevent accidents and minimize risks. These include:

- Obtaining necessary permits and approvals.

- Establishing clear communication and warning systems.

- Conducting thorough site inspections and risk assessments.

- Implementing proper storage, handling, and transportation of explosives.

- Using personal protective equipment, such as helmets, goggles, and earplugs.

- Controlling access to blasting areas and evacuating non-essential personnel.

- Following emergency response plans in the event of an incident.

6. Explain the process of monitoring and evaluating blasting results?

Monitoring and evaluating blasting results is crucial for optimizing performance and ensuring safety. The process involves:

- Observing and recording rock movement during the blast.

- Measuring fragmentation size and distribution.

- Analyzing vibration and noise data to assess environmental impact.

- Inspecting the blast site for any damage or hazards.

- Comparing actual results with planned outcomes to identify areas for improvement.

7. What are the potential environmental impacts of blasting operations and how can they be mitigated?

Blasting operations can have potential environmental impacts, including:

- Air pollution from dust, fumes, and gases.

- Noise and vibration from explosions.

- Water contamination from sediment runoff.

Mitigation measures include:

- Using low-emission explosives and dust suppressants.

- Implementing noise barriers and vibration monitoring systems.

- Controlling sediment runoff through proper drainage and erosion control measures.

8. Discuss the role of technology in modern blasting operations?

Technology plays a significant role in modern blasting operations, enhancing safety, efficiency, and accuracy. Examples include:

- GPS and laser scanning for precise hole placement and pattern design.

- Electronic detonators for controlled initiation and timing.

- Vibration monitoring systems for real-time data collection and analysis.

- Computer modeling and simulation tools for optimizing blast designs.

9. Describe the importance of ongoing training and professional development for Blasting Production Technicians?

Ongoing training and professional development are essential for Blasting Production Technicians to maintain their skills and knowledge in the rapidly evolving field. This includes:

- Regular safety refresher courses.

- Updates on new blasting techniques and technologies.

- Specialized training on specific types of explosives or blasting applications.

- Participation in industry conferences and workshops.

- Obtaining professional certifications, such as the Master Blaster certification.

10. What are your strengths and weaknesses as a Blasting Production Technician?

As a Blasting Production Technician, my strengths lie in my:

- Thorough understanding of blasting theory and practical applications.

- Proven ability to design and execute safe and efficient blasting operations.

- Strong attention to detail and commitment to quality.

- Excellent communication and interpersonal skills.

My area for improvement is:

- Gaining experience with the latest advancements in blasting technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blasting Production Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blasting Production Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Blasting Production Technician plays a crucial role in mining and construction operations, ensuring safe and efficient blasting practices. Their key responsibilities include:

1. Blasting Operations

Supervise and execute blasting operations according to established plans and safety protocols.

- Design and lay out blast patterns, determining hole spacing, burden, and stemming.

- Prepare and load explosives into blast holes, observing strict safety guidelines.

- Initiate blasts using appropriate methods, ensuring proper timing and sequence.

2. Quality Control

Monitor and evaluate blasting results to ensure adherence to specifications.

- Conduct post-blast inspections to assess fragmentation, vibration levels, and environmental impact.

- Analyze data and recommend adjustments to blasting plans to optimize performance.

3. Safety Management

Implement and enforce safety procedures to minimize risks during blasting operations.

- Establish and maintain a safe work environment, ensuring compliance with industry regulations.

- Train and supervise crew members on proper blasting techniques and safety protocols.

- Inspect and maintain equipment regularly to prevent malfunctions.

4. Equipment Operation

Operate various equipment and machinery used in blasting operations.

- Handle drilling rigs, explosives mixing trucks, and other specialized equipment.

- Maintain and calibrate instrumentation for accurate measurements and data collection.

Interview Preparation Tips

To ace the interview for a Blasting Production Technician position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, safety record, and industry best practices. This demonstrates your interest and preparation.

- Visit the company website and review their mission statement, values, and recent news.

- Read industry publications and attend relevant conferences to stay updated on advancements.

2. Highlight Your Technical Skills

Emphasize your expertise in blasting techniques, explosives handling, and safety protocols.

- Quantify your experience in designing and executing blast patterns, using specific examples and metrics.

- Discuss your knowledge of different explosives and their applications in different geological conditions.

- Explain your approach to risk assessment and mitigation strategies in blasting operations.

3. Demonstrate Safety Consciousness

Convey your strong commitment to safety and compliance in all aspects of your work.

- Describe your experience in developing and implementing safety plans and procedures.

- Highlight your ability to identify and manage potential hazards, ensuring a safe work environment.

- Discuss your understanding of regulatory requirements and industry standards related to blasting.

4. Showcase Teamwork and Communication Skills

Blasting operations require effective teamwork and communication. Emphasize your abilities in these areas.

- Describe your experience working as part of a team, coordinating tasks, and resolving conflicts.

- Highlight your ability to communicate clearly and effectively with colleagues, supervisors, and stakeholders.

- Discuss your experience in training and mentoring junior team members.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blasting Production Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!