Feeling lost in a sea of interview questions? Landed that dream interview for Bleach-Liquor Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bleach-Liquor Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

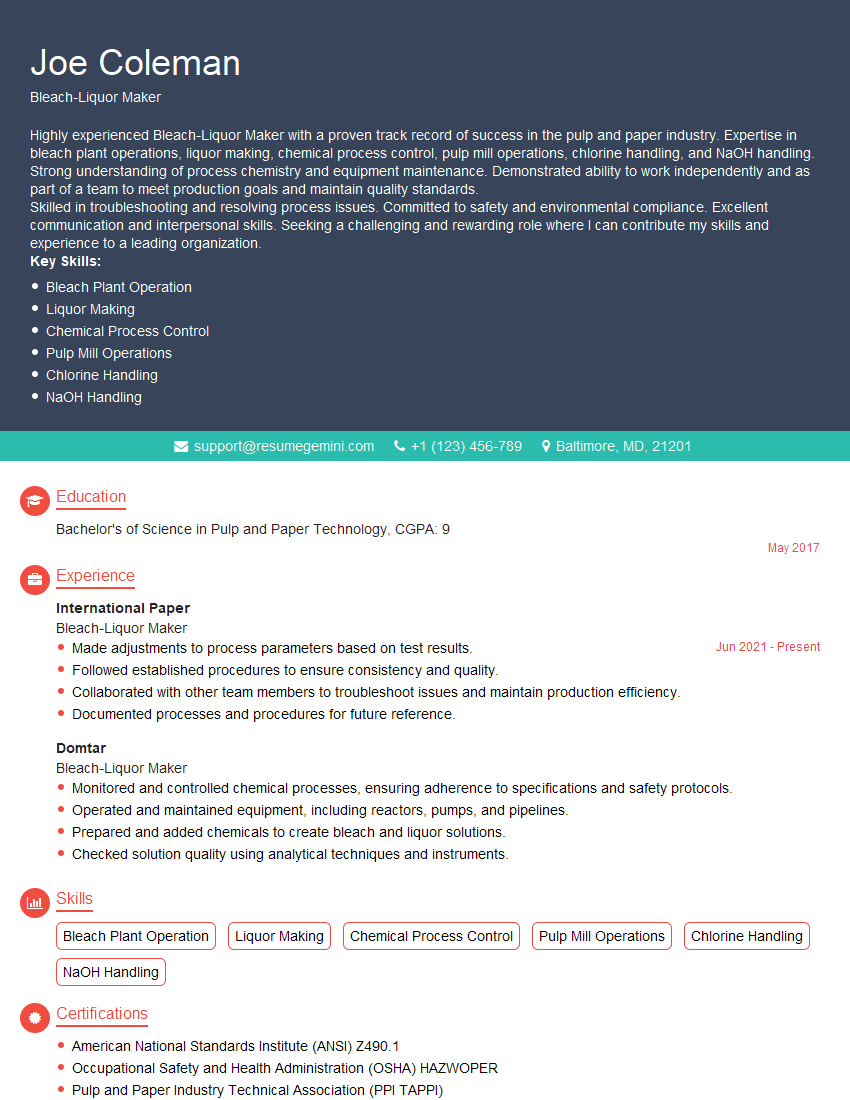

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bleach-Liquor Maker

1. Explain the process of manufacturing bleach liquor.

The manufacturing process of bleach liquor, also known as sodium hypochlorite solution, is as follows:

- Chlorination: Chlorine gas is bubbled into a cold, dilute solution of sodium hydroxide, resulting in the formation of sodium hypochlorite.

- Cooling: The reaction is exothermic, so the solution is cooled to maintain the desired concentration of sodium hypochlorite.

- Filtration: The solution is filtered to remove any impurities or suspended solids.

- Standardization: The concentration of the bleach liquor is adjusted to the desired level by adding more sodium hydroxide or chlorine as needed.

2. What are the different uses of bleach liquor in the paper industry?

Bleach liquor is primarily used in the paper industry as a bleaching agent to remove lignin from wood pulp, brighten paper, and improve its overall quality.

- Bleaching: Bleach liquor is used to selectively remove lignin from wood pulp, which is the main coloring agent, resulting in brighter and whiter paper.

- Brightness enhancement: It enhances the brightness of the paper by breaking down the chromophores responsible for absorbing light.

- Strength improvement: By removing lignin, bleach liquor improves the strength and durability of paper.

3. How do you control the pH of bleach liquor during the bleaching process?

Controlling the pH of bleach liquor is crucial for effective bleaching and to prevent the degradation of cellulose fibers. Here’s how I control it:

- pH Monitoring: I continuously monitor the pH of the bleach liquor using pH sensors or litmus paper.

- Acid Addition: If the pH is too high, I add small amounts of acid, such as sulfuric acid, to lower it.

- Caustic Addition: If the pH is too low, I add caustic soda (sodium hydroxide) to increase it.

4. What safety precautions should be taken when working with bleach liquor?

Working with bleach liquor requires strict adherence to safety precautions:

- Personal Protective Equipment: I wear appropriate personal protective equipment, including gloves, goggles, and a face shield, to prevent skin and eye contact.

- Ventilation: I ensure proper ventilation in the work area to avoid inhalation of chlorine gas.

- Spill Control: I have spill containment measures in place to manage any accidental spills or leaks.

- Emergency Response: I am trained in emergency response procedures in case of exposure to bleach liquor.

5. How do you maintain and calibrate the equipment used in bleach liquor production?

Maintaining and calibrating the equipment is crucial for efficient production and accurate chemical dosing:

- Regular Maintenance: I perform scheduled maintenance tasks, such as cleaning, lubricating, and inspecting equipment, to ensure its proper functioning.

- Calibration: I regularly calibrate sensors, flow meters, and other instruments used in bleach liquor production to ensure accurate measurements and dosing.

- Documentation: I maintain detailed records of maintenance and calibration activities for traceability and quality control purposes.

6. How do you optimize the efficiency of the bleach liquor bleaching process?

Optimizing the efficiency of the bleaching process is critical for reducing chemical consumption and improving paper quality:

- Process Control: I closely monitor and control process parameters such as temperature, pH, and chemical concentrations to ensure optimal bleaching conditions.

- Chemical Optimization: I collaborate with technical staff to evaluate and adjust chemical formulations to achieve the desired brightness and strength levels while minimizing chemical usage.

- Equipment Efficiency: I ensure that the equipment used in the bleaching process is operating efficiently by optimizing flow rates and minimizing downtime.

7. How do you handle and dispose of bleach liquor waste?

Proper handling and disposal of bleach liquor waste are essential for environmental protection:

- Waste Collection: I collect and store bleach liquor waste in designated containers.

- Waste Treatment: I follow established waste management protocols, which may involve chemical neutralization, biological treatment, or specialized disposal facilities.

- Compliance: I adhere to all applicable regulations and guidelines regarding the disposal of bleach liquor waste.

8. What factors influence the stability of bleach liquor?

The stability of bleach liquor is affected by several factors:

- Temperature: Higher temperatures accelerate the decomposition of bleach liquor, reducing its stability.

- pH: Extreme pH values, either too acidic or too alkaline, can destabilize bleach liquor.

- Light: Exposure to ultraviolet light can break down bleach liquor, causing a loss of available chlorine.

- Impurities: The presence of impurities, such as heavy metals or organic matter, can catalyze the decomposition of bleach liquor.

9. How do you ensure the quality of bleach liquor?

Ensuring bleach liquor quality is crucial for consistent bleaching results:

- Raw Material Inspection: I inspect incoming raw materials, such as chlorine gas and sodium hydroxide, to ensure they meet quality specifications.

- Process Control: I monitor and control the bleach liquor production process to ensure adherence to established standards.

- Regular Testing: I perform regular testing of bleach liquor to determine its concentration, pH, and other quality parameters.

- Quality Assurance: I participate in ongoing quality assurance programs to maintain high standards and improve processes.

10. How do you stay updated on the latest advancements and best practices in bleach liquor production?

Keeping up with advancements is important for continuous improvement:

- Technical Conferences: I attend industry conferences and workshops to learn about new technologies and best practices.

- Industry Publications: I read technical journals and publications to stay informed about research and development in the field.

- Collaboration: I collaborate with colleagues, peers, and suppliers to exchange knowledge and share experiences.

- Training and Education: I participate in training programs and continuing education courses to enhance my skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bleach-Liquor Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bleach-Liquor Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bleach-Liquor Makers are chemical manufacturing technicians responsible for preparing and operating the equipment used to create bleach liquor, a hazardous bleaching agent used in the manufacturing of paper and textiles. Their responsibilities include:

1. Batch Preparation

Bleach-Liquor Makers measure and mix chemicals to create batches of bleach liquor in accordance with established formulas and safety protocols.

2. Equipment Operation

Bleach-Liquor Makers operate a variety of equipment, including reactors, pumps, and valves, to manufacture and distribute bleach liquor.

3. Quality Control

Bleach-Liquor Makers conduct quality control tests to ensure that the bleach liquor meets the required specifications and adhere to environmental and safety regulations.

4. Process Monitoring and Optimization

Bleach-Liquor Makers monitor the production process to ensure that it is running efficiently and adjust parameters as needed to optimize production.

5. Equipment Maintenance and Troubleshooting

Bleach-Liquor Makers perform routine maintenance and repairs on equipment used in the production process and troubleshoot and resolve any issues that arise.

6. Safety and Regulatory Compliance

Bleach-Liquor Makers follow all safety regulations and guidelines and wear appropriate protective gear while handling hazardous chemicals.

Interview Tips

To ace the interview for a Bleach-Liquor Maker position, candidates should:

1. Research the company and industry

Bleach-Liquor Makers must be knowledgeable about the company they are applying to and the industry in which it operates. Research the company’s website, industry news, and recent developments to demonstrate your interest and understanding.

2. Prepare for technical questions

Bleach-Liquor Makers should be prepared to answer technical questions about the bleaching process, chemical handling, and equipment operation. Review the job description and research common interview questions to anticipate and prepare your answers.

3. Emphasize safety knowledge and experience

Bleach-Liquor Makers work with hazardous chemicals and must prioritize safety. Highlight your knowledge of safety protocols, chemical handling procedures, and emergency response measures.

4. Showcase your problem-solving abilities

Bleach-Liquor Makers often encounter process issues and equipment malfunctions. Describe previous experiences where you solved problems, identified root causes, and implemented effective solutions.

5. Highlight your attention to detail

Bleach-Liquor Makers must be meticulous and pay close attention to detail. Provide examples of your accuracy in following instructions, conducting quality control tests, and maintaining equipment.

6. Dress professionally and arrive on time

Bleach-Liquor Makers should dress professionally and arrive on time for their interview. A polished appearance and punctuality demonstrate respect and attention to detail.

7. Ask insightful questions

Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry. This shows your engagement and genuine interest in the position.

8. Practice your answers

Practice answering common interview questions in front of a mirror or with a friend or family member. This will help you feel more confident and polished during your actual interview.

9. Be enthusiastic and passionate

Bleach-Liquor Makers should convey their enthusiasm and passion for the chemical manufacturing industry. Express your interest in the role and your eagerness to contribute your skills and experience.

10. Follow up

After the interview, send a thank-you note to the interviewer within 24 hours. Reiterate your interest in the position and highlight any specific skills or experiences that make you a suitable candidate.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bleach-Liquor Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.