Are you gearing up for a career in Blender/Braze Applicator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Blender/Braze Applicator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

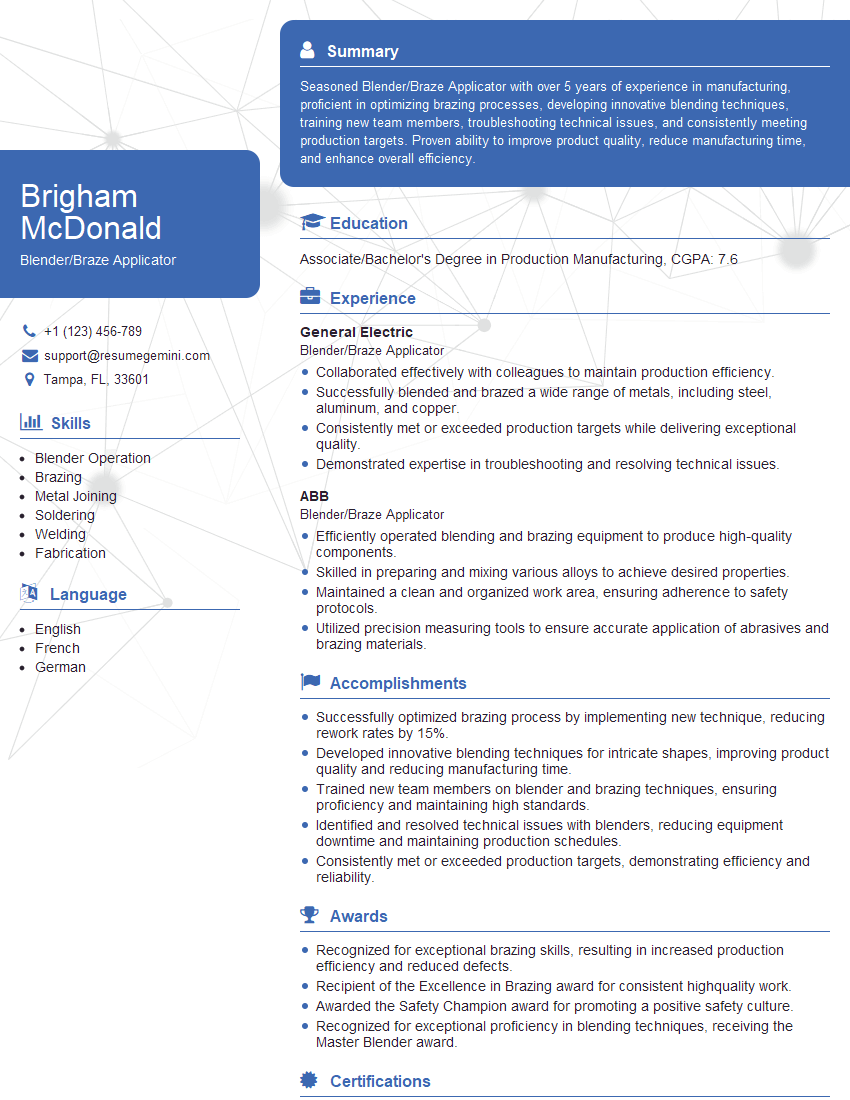

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blender/Braze Applicator

1. What are the key differences between brazing and welding?

Brazing and welding are two distinct metalworking processes that use different techniques and materials to join metal pieces together. Here are the key differences between brazing and welding:

- Melting Points: Brazing uses a filler metal with a lower melting point than the base metals being joined, whereas welding uses a filler metal with a higher melting point than the base metals.

- Bond Strength: Brazed joints are typically weaker than welded joints due to the lower melting point of the filler metal.

- Flux: Brazing requires the use of a flux to clean the surface of the metal and promote bonding, while welding does not require flux.

- Applications: Brazing is often used for joining dissimilar metals or for creating thin, delicate joints, while welding is typically used for joining thicker, stronger metal pieces.

2. What safety precautions should be taken when brazing?

PPE

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a respirator.

Ventilation

- Ensure that the work area is well-ventilated to remove fumes and gases released during brazing.

Fire Safety

- Keep a fire extinguisher nearby and have a plan in place for extinguishing any fires that may occur.

Electrical

- Use properly grounded equipment and avoid touching live electrical components.

Post-Brazing

- Allow the brazed joint to cool completely before handling to prevent burns.

3. What are the different types of brazing methods?

- Torch Brazing: Uses a torch to heat the joint and apply the filler metal.

- Induction Brazing: Uses an induction coil to generate heat and melt the filler metal.

- Furnace Brazing: Places the joint in a furnace to heat and melt the filler metal.

- Dip Brazing: Dips the joint into a molten bath of filler metal.

- Resistance Brazing: Uses electrical resistance to generate heat and melt the filler metal.

4. How do you prepare a metal surface for brazing?

- Clean the surface to remove dirt, grease, and oxides.

- Apply flux to the surface to promote bonding.

- If necessary, use a mechanical method (e.g., sanding, grinding) to create a clean, smooth surface.

5. What are the common problems that can occur during brazing?

- Porosity: Holes or voids in the brazed joint caused by trapped gas or insufficient heat.

- Cracking: Fractures in the brazed joint caused by excessive heat or stress.

- Cold Joints: Joints that have not been properly heated or melted, resulting in a weak bond.

- Flux Inclusions: Trapped flux within the brazed joint, which can weaken the bond.

- Oxidation: Formation of oxides on the surface of the metal, which can interfere with bonding.

6. How do you determine the correct brazing temperature?

- Refer to the manufacturer’s specifications for the filler metal being used.

- Use a temperature-indicating crayon or pyrometer to measure the temperature of the joint.

- For torch brazing, adjust the flame to achieve the desired temperature.

- For other brazing methods, follow the manufacturer’s instructions for setting the appropriate temperature.

7. What are the different types of brazing fluxes?

- Acid Fluxes: Highly corrosive and effective, but require post-cleaning to remove residues.

- Neutral Fluxes: Less corrosive than acid fluxes, but may require longer heating times.

- Water-Soluble Fluxes: Can be easily removed with water after brazing.

- Organic Fluxes: Non-corrosive and suitable for use on sensitive materials.

8. How do you maintain and calibrate a brazing torch?

Maintenance

- Clean the torch tip and nozzle regularly to prevent clogging.

- Check and replace O-rings and seals to ensure proper gas flow.

Calibration

- Use a gas flow meter to calibrate the gas flow rates for oxygen and fuel.

- Adjust the flame to achieve the correct temperature and flame characteristics.

9. What is the difference between a reducing and an oxidizing flame?

- Reducing Flame: Contains an excess of fuel, creating a flame with a dark blue inner cone and a luminous outer cone. This flame is suitable for brazing most metals, as it protects them from oxidation.

- Oxidizing Flame: Contains an excess of oxygen, creating a flame with a sharp blue inner cone and a pale outer cone. This flame is not suitable for brazing, as it can cause oxidation and weaken the joint.

10. Can you describe the different types of joint designs used in brazing?

- Butt Joint: Two pieces of metal are joined edge-to-edge.

- Lap Joint: One piece of metal overlaps the other.

- T-Joint: One piece of metal is perpendicular to the other.

- Edge Joint: Two pieces of metal are joined at their edges.

- Scarf Joint: The edges of two pieces of metal are beveled and joined.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blender/Braze Applicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blender/Braze Applicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blender/Braze Applicators are responsible for mixing and applying braze alloys to metal surfaces to join them together. They use a variety of tools and equipment to perform their job, including blenders, brazing torches, and fluxes. Blender/Braze Applicators must have a good understanding of the brazing process and the properties of different brazing alloys. They must also be able to work independently and as part of a team.

1. Mix brazing alloys according to specified proportions.

Blender/Braze Applicators must be able to accurately mix brazing alloys according to the manufacturer’s specifications. The proportions of the alloy will vary depending on the type of metal being joined and the desired strength of the joint.

- Measure and weigh the appropriate amounts of each alloy.

- Place the alloys in a blender and mix until they are thoroughly combined.

- Add flux to the mixture and blend until it is evenly distributed.

2. Apply brazing alloy to metal surfaces.

Blender/Braze Applicators use a variety of tools to apply brazing alloy to metal surfaces. These tools include brushes, spatulas, and torches. The method of application will vary depending on the type of metal being joined and the desired strength of the joint.

- Apply the brazing alloy to the metal surfaces using a brush or spatula.

- Heat the metal surfaces with a torch until the brazing alloy melts and flows into the joint.

- Allow the joint to cool and solidify.

3. Inspect brazed joints for defects.

Blender/Braze Applicators must be able to inspect brazed joints for defects. These defects can include cracks, voids, and inclusions. Blender/Braze Applicators must be able to identify these defects and take corrective action if necessary.

- Visually inspect the brazed joint for any defects.

- Use a magnifying glass to inspect the joint for any small defects.

- Perform a leak test to check for any leaks in the joint.

4. Maintain equipment and work area.

Blender/Braze Applicators must be able to maintain their equipment and work area. This includes cleaning and lubricating equipment, as well as keeping the work area clean and organized. Blender/Braze Applicators must also be able to identify and troubleshoot any problems with their equipment.

- Clean and lubricate equipment regularly.

- Keep the work area clean and organized.

- Identify and troubleshoot any problems with equipment.

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to help you ace your interview for a Blender/Braze Applicator position.

1. Research the company and the position.

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the expectations of the role. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and make sure you understand the requirements of the role.

- Look up the company on Glassdoor to see what other employees have to say about working there.

2. Practice answering common interview questions.

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It can be helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Write down a list of common interview questions and practice answering them out loud.

- Time yourself to make sure you can answer each question in under two minutes.

- Ask a friend or family member to give you feedback on your answers.

3. Be prepared to talk about your experience.

The interviewer will likely ask you about your experience in blending and brazing. Be prepared to talk about your skills and knowledge, as well as any projects you have worked on.

- Quantify your experience by using numbers and metrics.

- Highlight your skills and knowledge that are relevant to the position.

- Be prepared to talk about your experience in a team environment.

4. Dress appropriately.

First impressions matter, so it is important to dress appropriately for your interview. For a Blender/Braze Applicator position, you should wear clean, comfortable clothes that are appropriate for a manufacturing environment.

- Wear closed-toe shoes and long pants.

- Avoid wearing loose clothing or jewelry that could get caught in equipment.

- Make sure your clothes are clean and wrinkle-free.

5. Be on time.

Punctuality is important for any job interview, but it is especially important for a job in manufacturing. Being on time shows the interviewer that you are respectful of their time and that you are serious about the job.

- Plan your route to the interview location in advance.

- Give yourself plenty of time to get to the interview, even if you think you know the way.

- If you are running late, call the interviewer to let them know.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blender/Braze Applicator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blender/Braze Applicator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.