Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

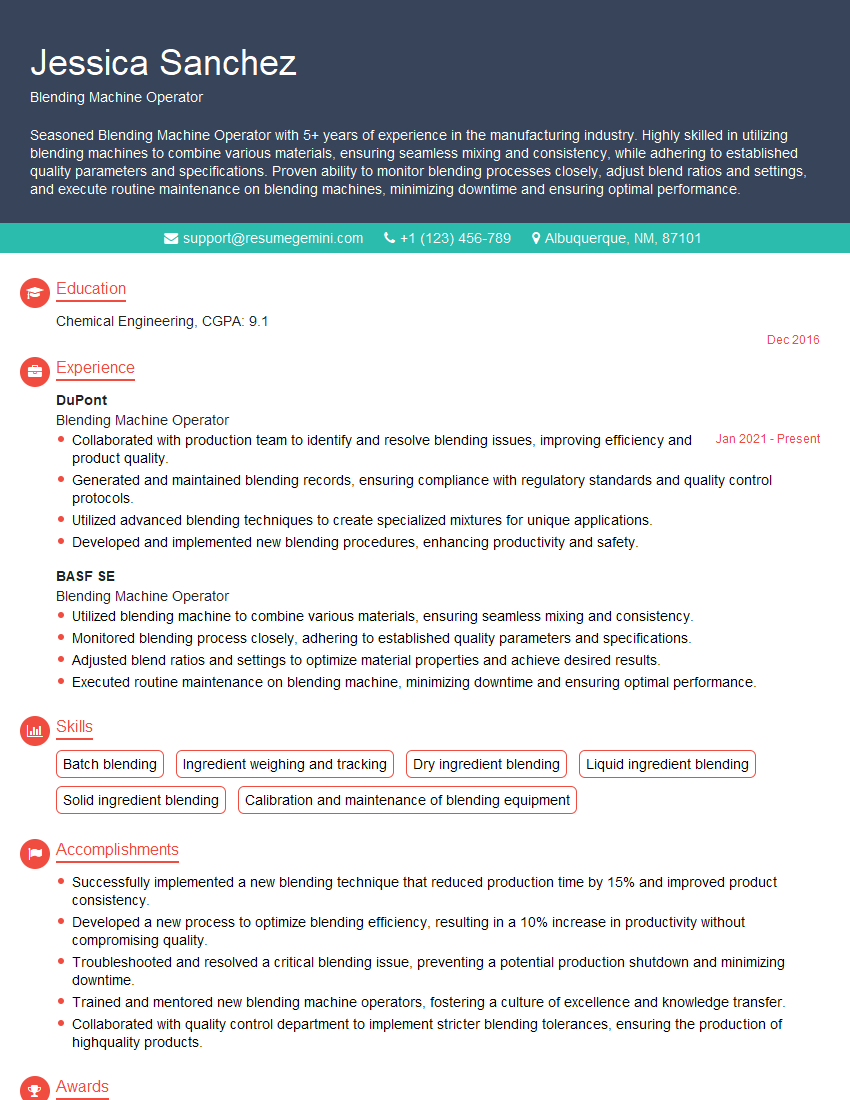

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Machine Operator

1. Describe the role of a Blending Machine Operator?

A Blending Machine Operator is responsible for operating and maintaining blending machines to produce high-quality blended materials. They work in various industries, such as food, pharmaceuticals, and chemicals.

- Operating blending machines to blend different materials, such as powders, liquids, and granules.

- Monitoring the blending process to ensure that the desired blend is achieved.

- Cleaning and maintaining blending machines to ensure optimal performance.

- Following standard operating procedures (SOPs) and adhering to safety regulations.

- Working with other operators and supervisors to optimize the blending process.

2. Explain the different types of blending machines and their applications?

Batch Blenders:

- Suitable for small to medium batches.

- Used in food, pharmaceutical, and chemical industries.

Continuous Blenders:

- Capable of handling large volumes of material.

- Used in industries with high production requirements.

Twin-shaft Blenders:

- Provide thorough blending.

- Used in applications requiring high precision.

3. What are the critical parameters to consider when setting up a blending machine?

- Blend uniformity: Ensuring the materials are evenly distributed throughout the blend.

- Blend time: Optimizing the blending time to achieve the desired blend quality.

- Batch size: Determining the appropriate batch size for the blending machine’s capacity.

- Material properties: Considering the physical and chemical properties of the materials being blended.

- Equipment capabilities: Understanding the limitations and capabilities of the blending machine being used.

4. How do you troubleshoot common problems encountered while operating a blending machine?

- Uneven Blending: Verifying the machine settings, checking for blockages, and adjusting the impeller speed.

- Overheating: Monitoring the temperature and reducing the batch size or blending time if necessary.

- Mechanical Issues: Inspecting belts, gears, and other components for damage or wear.

- Electrical Faults: Checking fuses, wiring, and electrical connections.

- Contamination: Ensuring proper cleaning and sanitization procedures are followed.

5. What safety precautions should be taken when working with blending machines?

- Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a mask.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Keeping the work area clean and free of tripping hazards.

- Never operating a blending machine without proper training and authorization.

- Being aware of potential hazards, such as dust, fumes, and moving parts.

6. How do you ensure that the blended materials meet quality standards?

- Following standard operating procedures (SOPs) and established quality control protocols.

- Monitoring blend uniformity and other critical parameters during the blending process.

- Performing regular checks and inspections of the equipment and materials.

- Documenting blending parameters and quality control data for traceability.

- Working closely with quality control personnel to ensure compliance with specifications.

7. What maintenance procedures are essential for prolonging the life of a blending machine?

- Regular cleaning and lubrication of all moving parts.

- Inspecting belts, seals, and gaskets for wear or damage.

- Performing preventive maintenance tasks, such as changing filters and checking electrical connections.

- Calibrating the machine according to manufacturer’s specifications.

- Keeping a detailed maintenance log for tracking repairs and replacements.

8. How do you optimize the efficiency of a blending process?

- Choosing the appropriate blending machine for the specific materials and application.

- Setting optimal blending parameters, such as blend time and impeller speed.

- Minimizing batch size variations to maintain consistent blending results.

- Streamlining the material handling process to reduce downtime.

- Implementing a preventive maintenance program to avoid breakdowns.

9. Describe your experience in working with different types of blending equipment?

Throughout my career, I have gained experience working with various types of blending equipment, including batch blenders, continuous blenders, and twin-shaft blenders. I am familiar with the capabilities and limitations of each type and can effectively operate and maintain them.

- Batch Blender: XYZ Industries, 2018-2021

- Continuous Blender: ABC Manufacturing, 2015-2018

10. How do you stay updated on the latest advancements in blending technology?

- Attending industry conferences and workshops.

- Reading trade journals and research papers.

- Consulting with equipment manufacturers and industry experts.

- Participating in online forums and discussion groups.

- Seeking opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blending Machine Operators play a pivotal role in ensuring the quality of products in food, pharmaceutical, and chemical industries. Their primary responsibilities include:

1. Machine Operation

Skilfully operate blending machines, adhering to prescribed procedures and maintaining optimal production rates.

- Configure machines according to specific product formulations.

- Load and unload raw materials, ensuring accurate weighing and measurement.

2. Quality Control

Monitor blending processes to maintain product consistency and meet quality standards.

- Conduct in-process checks and collect samples for analysis.

- Calibrate and maintain equipment to ensure accuracy and precision.

3. Production Management

Coordinate with production teams to ensure efficient blending operations and timely delivery.

- Monitor production schedules and adjust blending parameters as needed.

- Identify and resolve production issues promptly to minimize downtime.

4. Maintenance and Troubleshooting

Perform basic maintenance tasks and troubleshoot minor equipment issues.

- Clean and lubricate blending machines as per maintenance schedules.

- Identify and report major mechanical or electrical issues for timely repair.

Interview Tips

To ace your interview for a Blending Machine Operator position, consider the following tips:

1. Research the Industry

Familiarize yourself with the food, pharmaceutical, or chemical industry your potential employer operates in. This demonstrates your interest and understanding of the sector.

- Read industry news and publications to stay updated on trends and best practices.

- Research the specific company’s products and market position.

2. Highlight Relevant Skills

Emphasize your experience in blending operations, quality control, and production management. Quantify your accomplishments whenever possible.

- Provide specific examples of how you ensured product quality and maintained high production rates.

- Describe your experience with different types of blending machines and how you adapted to their unique operating characteristics.

3. Showcase Problem-Solving Abilities

Interviewers are keen on candidates who can effectively troubleshoot and resolve issues. Share examples of how you identified and fixed blending problems.

- Explain how you analyzed process parameters and adjusted settings to optimize blending efficiency.

- Describe how you resolved equipment malfunctions to minimize downtime.

4. Demonstrate Safety Awareness

Blending operations involve potential hazards. Emphasize your commitment to safety by highlighting your knowledge of safety procedures and regulations.

- Explain how you ensure proper handling of hazardous materials.

- Share your experience with safety training and certification programs.

Next Step:

Now that you’re armed with the knowledge of Blending Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blending Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini