Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

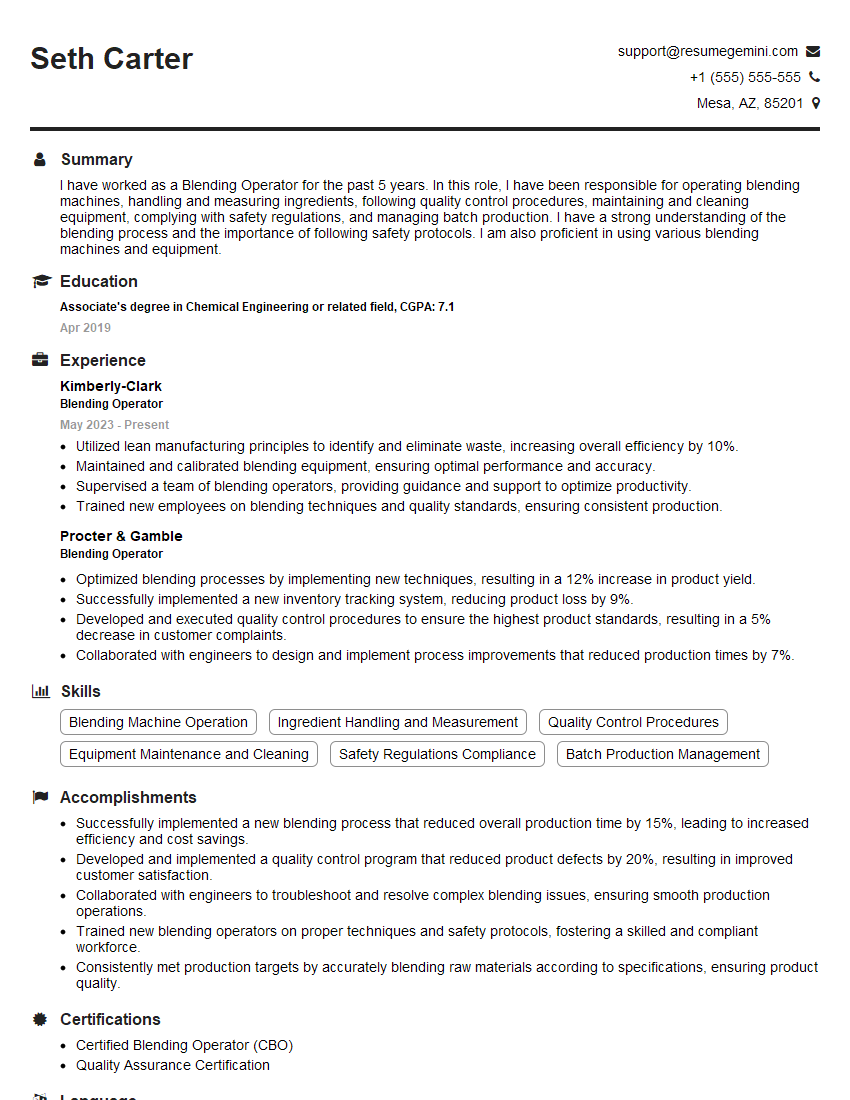

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Operator

1. Describe the key responsibilities of a Blending Operator?

- Operate and monitor blending equipment to mix and combine different ingredients according to specified formulations.

- Ensure accurate weighing, measuring, and blending of ingredients to meet product specifications.

- Monitor blending processes and make adjustments as needed to maintain product quality and consistency.

- Maintain a clean and organized work area, adhering to safety protocols and Good Manufacturing Practices (GMPs).

2. How do you ensure accurate weighing and measurement of ingredients during blending?

Weighing Procedures

- Calibrate scales regularly to ensure accuracy.

- Use the appropriate weighing equipment for the required precision.

- Follow established weighing procedures, including proper tare and double-checking.

Measuring Techniques

- Use calibrated measuring devices, such as pipettes or graduated cylinders.

- Read measurements carefully and record them accurately.

- Convert measurements between units if necessary, using established conversion factors.

3. What types of blending techniques are commonly used in industrial settings?

- Batch Blending: Mixing ingredients in a specific order and quantity in a batch-style process.

- Continuous Blending: Gradually adding ingredients to a continuous flow of product.

- In-Line Blending: Mixing ingredients directly into a process stream or pipeline.

- High-Shear Blending: Using high-powered equipment to thoroughly mix ingredients with different viscosities.

4. How do you maintain product quality and consistency during blending operations?

- Follow established blending procedures and formulations precisely.

- Monitor blending processes using appropriate instrumentation and record data.

- Conduct regular quality checks on blended products, including visual inspections and laboratory testing.

- Make adjustments to blending parameters as needed to achieve desired product specifications.

5. Describe the safety precautions that must be followed when operating blending equipment?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Ensure that all equipment is properly grounded and electrical connections are secure.

- Follow lockout/tagout procedures when performing maintenance or repairs on equipment.

- Handle chemicals and hazardous materials with care, according to established safety protocols.

6. How do you troubleshoot common problems encountered during blending operations?

- Product inconsistency: Check blending parameters, equipment calibration, and ingredient quality.

- Incomplete mixing: Increase blending time or use higher shear force.

- Equipment malfunction: Inspect equipment, check electrical connections, and contact maintenance personnel.

- Safety concerns: Stop operations immediately, identify the hazard, and follow established safety protocols.

7. What techniques do you use to ensure proper sampling and testing of blended products?

- Use representative sampling techniques to obtain accurate samples.

- Follow established sampling protocols to avoid contamination or bias.

- Conduct appropriate testing methods, such as chemical analysis or physical measurements, to evaluate product quality.

- Record and document all sampling and testing data for future reference.

8. How do you optimize blending processes to improve efficiency and reduce waste?

- Analyze blending data to identify areas for improvement.

- Adjust blending parameters, such as mixing time and speed, to optimize product quality and minimize waste.

- Implement automation and process control systems to improve consistency and efficiency.

- Train operators on best practices and provide continuous feedback to promote continuous improvement.

9. What are the key quality control measures implemented during blending operations?

- Establish product specifications and acceptance criteria.

- Conduct regular quality checks on ingredients and finished products.

- Maintain accurate records of blending processes and quality control data.

- Implement corrective actions when quality issues are identified.

10. How do you stay updated on advancements in blending technologies and practices?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Consult with equipment manufacturers and industry experts.

- Participate in online forums and discussions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blending Operators play a crucial role in the production process, ensuring the creation of high-quality products. Their primary duties include:

1. Blending Operations

Operate blending equipment to combine raw materials or finished products according to established formulas or recipes.

- Maintain accurate records of blending operations, including materials used, quantities, and equipment settings.

- Monitor blending processes to ensure proper mixing and adherence to specifications.

2. Quality Control

Conduct regular quality checks on blended products, ensuring they meet established standards.

- Identify and resolve any deviations from quality specifications.

- Document quality control results and report any issues to supervisors.

3. Equipment Maintenance

Perform routine maintenance and cleaning of blending equipment, ensuring its optimal performance.

- Calibrate and adjust equipment settings as needed.

- Identify potential equipment issues and report them promptly for repairs.

4. Safety and Compliance

Adhere to all safety regulations and guidelines in the workplace.

- Wear appropriate personal protective equipment (PPE) at all times.

- Follow established safety protocols for handling chemicals and materials.

Interview Preparation Tips

To ace your interview for a Blending Operator position, consider these helpful preparation tips:

1. Research the Company and Role

Thoroughly research the company’s background, products, and industry to demonstrate your knowledge and interest.

- Prepare specific questions about the company’s blending operations and their approach to quality control.

- Identify any unique skills or experiences that you possess that align with the company’s needs.

2. Highlight Your Technical Skills

Emphasize your proficiency in blending operations, including the use of equipment, recipe management, and quality control techniques.

- Quantify your accomplishments and provide specific examples of how you have successfully blended different materials.

- Discuss your understanding of blending principles and the factors that influence blending quality.

3. Showcase Your Quality Control Expertise

Demonstrate your knowledge of quality control standards and your ability to identify and resolve product defects.

- Describe your experience in conducting quality inspections, documenting results, and implementing corrective actions.

- Explain how you prioritize quality and ensure that blended products meet customer specifications.

4. Prepare Safety-Related Questions

Safety is paramount in a manufacturing environment. Show that you prioritize safety by asking thoughtful questions about the company’s safety protocols.

- Inquire about the company’s training and safety policies for blending operators.

- Ask about the safety measures in place to handle hazardous materials and prevent accidents.

Next Step:

Now that you’re armed with the knowledge of Blending Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blending Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini