Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Tank Tender Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

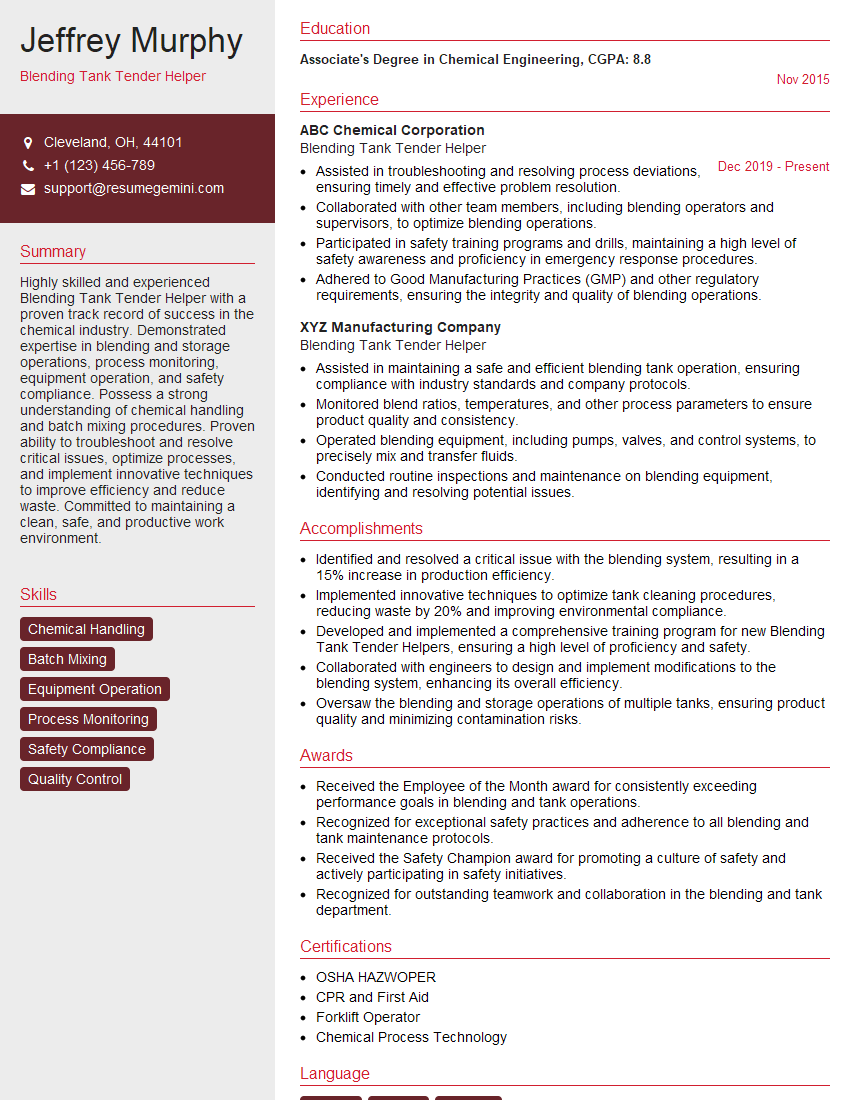

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Tank Tender Helper

1. What are the key responsibilities of a Blending Tank Tender Helper?

As a Blending Tank Tender Helper, I would be responsible for a variety of tasks, including:

- Assisting in the blending of various chemicals and liquids according to specified formulas

- Monitoring and maintaining the blending process to ensure the accuracy and quality of the blended products

- Cleaning and maintaining the blending tanks and associated equipment to meet safety and quality standards

- Performing routine inspections and troubleshooting of the blending system to identify and resolve any issues

- Following established safety procedures and maintaining a clean and organized work area

2. How do you ensure the accuracy and consistency of the blending process?

Maintaining Equipment and Calibration

- Regularly inspect and calibrate blending tanks, pumps, and instrumentation to ensure accuracy

- Use precise measuring devices and follow standard operating procedures to ensure correct ingredient ratios

Monitoring and Control

- Continuously monitor the blending process and make adjustments as needed to maintain desired parameters

- Analyze samples and compare them to specifications to verify product quality

Documentation and Record-Keeping

- Maintain accurate records of blending operations, including ingredient quantities, blending times, and product specifications

- Document any deviations or adjustments made during the process to ensure traceability and quality control

3. How do you handle potential hazards and emergencies that may arise during the blending process?

To ensure safety and minimize risks during the blending process, I would adhere to the following protocols:

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and protective clothing

- Identify and assess potential hazards associated with the chemicals and equipment used

- Follow established safety procedures for handling hazardous materials and operating machinery

- Be aware of emergency response protocols and know how to contact emergency services if necessary

- Maintain a clean and organized work area to prevent spills and accidents

4. How do you prioritize your tasks and manage your time effectively?

To effectively prioritize my tasks and manage my time, I would implement the following strategies:

- Create a daily or weekly task list and prioritize tasks based on urgency and importance

- Break down large or complex tasks into smaller, manageable steps

- Delegate tasks to others when necessary and provide clear instructions and support

- Use a calendar or planner to schedule tasks and appointments

- Take breaks throughout the day to maintain focus and productivity

5. How do you maintain a clean and organized work area?

To ensure a clean and organized work area, I would implement a systematic approach:

- Regularly clean and disinfect work surfaces, equipment, and tools to prevent contamination

- Properly label and store chemicals and materials to maintain inventory control

- Dispose of waste and spills promptly and follow proper disposal procedures

- Involve team members in maintaining a clean and organized work environment

- Conduct regular inspections to identify and address any areas that need improvement

6. Can you describe a situation where you had to troubleshoot a problem with the blending system and how you resolved it?

Identifying the Problem

- Observed an unexpected change in the blended product quality

- Checked equipment readings and process parameters to identify deviations

Troubleshooting and Resolution

- Inspected the blending tank for leaks or blockages

- Verified the accuracy of ingredient ratios and adjusted as needed

- Recalibrated the blending equipment to ensure precise measurements

- Consulted with a supervisor or technical expert for guidance

- Implemented corrective actions and monitored the process to ensure resolution

7. How do you stay updated on industry best practices and technological advancements in blending operations?

- Attend industry conferences and workshops to learn about new techniques and technologies

- Read technical journals and articles to stay informed about advancements in the field

- Network with other professionals in the industry to exchange knowledge and best practices

- Participate in training programs offered by equipment manufacturers or industry organizations

- Seek opportunities to contribute to industry discussions and research

8. How do you ensure that the blended products meet the required specifications and quality standards?

Monitoring and Control

- Monitor the blending process closely and make adjustments as needed to maintain desired parameters

- Take samples of the blended products and analyze them to verify compliance with specifications

Documentation and Record-Keeping

- Maintain accurate records of blending operations, including ingredient quantities, blending times, and product specifications

- Document any deviations or adjustments made during the process to ensure traceability and quality control

Continuous Improvement

- Regularly review blending processes and identify areas for improvement

- Implement quality control measures and conduct audits to ensure ongoing compliance

- Collaborate with other departments, such as quality assurance, to address any issues and enhance product quality

9. How do you maintain a positive work attitude and contribute to a productive team environment?

- Maintain a positive and enthusiastic attitude, even when facing challenges

- Communicate effectively with team members and foster a collaborative work environment

- Be willing to help others and share knowledge and expertise

- Recognize and appreciate the contributions of others

- Actively participate in team discussions and decision-making processes

10. How do you handle stress and pressure in a fast-paced blending operation?

- Maintain composure and prioritize tasks effectively under pressure

- Communicate clearly and calmly with colleagues and supervisors

- Take regular breaks to avoid burnout and maintain focus

- Seek support from team members or supervisors when needed

- Practice relaxation techniques or mindfulness exercises to manage stress

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Tank Tender Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Tank Tender Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Blending Tank Tender Helper

The Blending Tank Tender Helper plays a vital role in ensuring the efficient and safe operation of blending tanks in a production facility.

1. Monitor and Control Blending Processes

The tender helper continuously monitors the blending process, maintaining precise ratios of ingredients and adjusting settings as needed.

- Records and documents blending parameters

- Collects samples for quality control

2. Inspect and Maintain Equipment

The helper performs regular inspections and preventive maintenance on blending tanks and related equipment.

- Cleans and sanitizes tanks and pipelines

- Replaces filters and other components

3. Assist with Blending Tank Preparation

The tender helper assists in preparing tanks for blending, ensuring proper setup and calibration.

- Loads ingredients into tanks

- Verifies blending recipes and specifications

4. Support other Blending Operations

The helper supports other blending operations as necessary, such as transferring blends, cleaning equipment, and troubleshooting issues.

- Assists with blending operations

- Provides technical support

Interview Preparation Tips for Blending Tank Tender Helper Candidates

To ace the interview, candidates should come prepared with a thorough understanding of the job responsibilities and the industry. Here are some tips:

1. Research the Company and Industry

Learn about the company’s products, services, and values. Familiarize yourself with industry trends and best practices.

2. Highlight Relevant Skills and Experience

Emphasize skills in blending operations, equipment maintenance, quality control, and safety procedures. Share specific examples of your experience.

3. Practice Your Answers

Anticipate common interview questions and prepare responses that showcase your qualifications and enthusiasm for the role.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest in the position and the company. Inquire about career growth opportunities or the company’s commitment to sustainability.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blending Tank Tender Helper, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blending Tank Tender Helper positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.