Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Tank Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

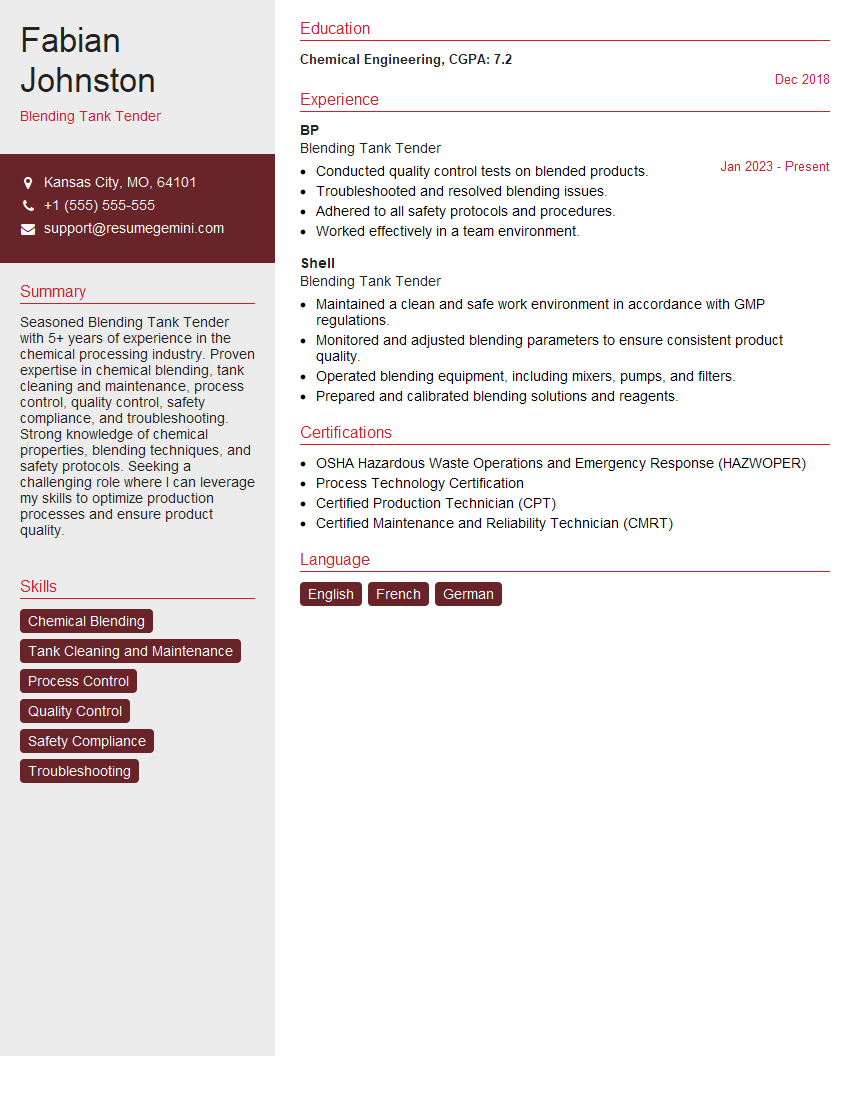

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Tank Tender

1. What is the purpose of a blending tank?

The purpose of a blending tank is to mix different liquids or gases in order to create a uniform mixture. Blending tanks are used in a variety of industries, including the food and beverage, chemical, and pharmaceutical industries.

2. What are the different types of blending tanks?

Horizontal Blending Tanks

- Cylindrical in shape and have a horizontal orientation.

- Used for blending liquids with different viscosities.

- Equipped with agitators to ensure thorough mixing.

Vertical Blending Tanks

- Cylindrical in shape and have a vertical orientation.

- Used for blending liquids with similar viscosities.

- May have multiple mixing impellers for efficient blending.

3. What are the key factors to consider when selecting a blending tank?

When selecting a blending tank, it is important to consider the following factors:

- The volume of liquid to be blended

- The viscosity of the liquids to be blended

- The desired mixing time

- The available space

- The budget

4. What are the different types of agitators used in blending tanks?

Propeller Agitators

- Consist of a propeller-shaped blade attached to a shaft.

- Provide axial flow, creating a top-to-bottom mixing pattern.

- Suitable for blending liquids with low to medium viscosities.

Turbine Agitators

- Comprise a disc with radial blades mounted on a shaft.

- Generate radial flow, creating a side-to-side mixing pattern.

- Ideal for blending liquids with high viscosities.

Paddle Agitators

- Feature flat blades attached to a central shaft.

- Provide gentle mixing and are suitable for blending delicate liquids.

- Used in applications where shear sensitivity is a concern.

5. How do you maintain a blending tank?

To maintain a blending tank, it is important to:

- Clean the tank regularly to prevent the buildup of contaminants.

- Inspect the tank and its components regularly for any signs of wear or damage.

- Lubricate the moving parts of the tank regularly.

- Calibrate the tank’s instruments regularly to ensure accuracy.

6. What are the safety precautions that should be taken when operating a blending tank?

When operating a blending tank, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Ensure that the tank is properly grounded to prevent electrical hazards.

- Never enter a blending tank that is in operation.

- Be aware of the potential for spills and leaks.

- Follow all operating procedures carefully.

7. What is the role of a Blending Tank Tender?

The role of a Blending Tank Tender is to operate and maintain blending tanks in a variety of industries. Blending Tank Tenders are responsible for:

- Preparing and mixing different liquids or gases according to specified formulas.

- Monitoring the blending process to ensure that the desired mixture is achieved.

- Cleaning and maintaining blending tanks and their components.

- Following safety procedures and regulations.

8. What are the qualifications and skills required to be a Blending Tank Tender?

To be a successful Blending Tank Tender, you should have the following qualifications and skills:

- A high school diploma or equivalent

- Experience in operating and maintaining blending tanks

- Knowledge of blending processes and procedures

- Ability to follow instructions and work independently

- Strong attention to detail

- Ability to work in a team environment

9. What is the career path for a Blending Tank Tender?

Blending Tank Tenders can advance their careers by becoming Blending Tank Supervisors or Blending Tank Managers. With experience and additional training, they can also move into roles in quality control or production management.

10. What is the salary range for a Blending Tank Tender?

The salary range for a Blending Tank Tender can vary depending on experience, location, and industry. According to Indeed, the average salary for a Blending Tank Tender in the United States is around $45,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Tank Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Tank Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blending Tank Tenders are responsible for a range of duties related to the blending and storage of different liquids in a production or processing facility. Their core responsibilities may include:

1. Blending and Mixing Liquid Ingredients

Accurately blend and mix various liquids according to specified formulas and recipes.

- Follow instructions to add precise quantities of each liquid into the blending tank

- Utilize mixing equipment and techniques to achieve uniform and consistent blends

2. Tank Maintenance

Maintain and clean blending tanks to ensure optimal performance and prevent contamination.

- Inspect tanks for any damages or leaks, and report any issues promptly

- Clean tanks thoroughly after each use to prevent contamination and maintain hygiene

3. Quality Control

Perform quality checks on blended liquids to ensure they meet specifications.

- Collect samples and conduct tests to verify the quality and consistency of blends

- Record and document quality control data for each batch of liquid produced

4. Inventory Management

Monitor and maintain inventory levels of liquids used in the blending process.

- Track the usage and consumption of liquids to ensure adequate supply

- Coordinate with warehouse or suppliers to replenish stock as needed

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your Blending Tank Tender interview:

1. Research the Role and Company

Familiarize yourself with the specific responsibilities and requirements of the Blending Tank Tender position by studying the job description.

- Visit the company’s website to learn about their products, services, and values

- Research industry trends and best practices related to blending and tank management

2. Highlight Relevant Experience and Skills

In your resume and interview, emphasize your previous experience in handling liquids, blending operations, and maintaining production equipment.

- Provide specific examples of your abilities in accurately measuring, mixing, and maintaining tanks

- Showcase your attention to detail and commitment to quality control procedures

3. Be Prepared to Discuss Safety Protocols

Employers prioritize safety in production facilities. During the interview, be ready to discuss your knowledge of safety regulations and your experience in following safety protocols.

- Explain your understanding of potential hazards associated with blending liquids and handling chemicals

- Emphasize your adherence to safety procedures and your ability to work in a safe and organized manner

4. Show Enthusiasm and Eagerness to Learn

Express your passion for working in a production environment and your interest in the blending process.

- Convey your willingness to learn new techniques and improve your skills

- Ask thoughtful questions about the company’s operations and your potential contributions to the team

Next Step:

Now that you’re armed with the knowledge of Blending Tank Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blending Tank Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini