Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blending Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

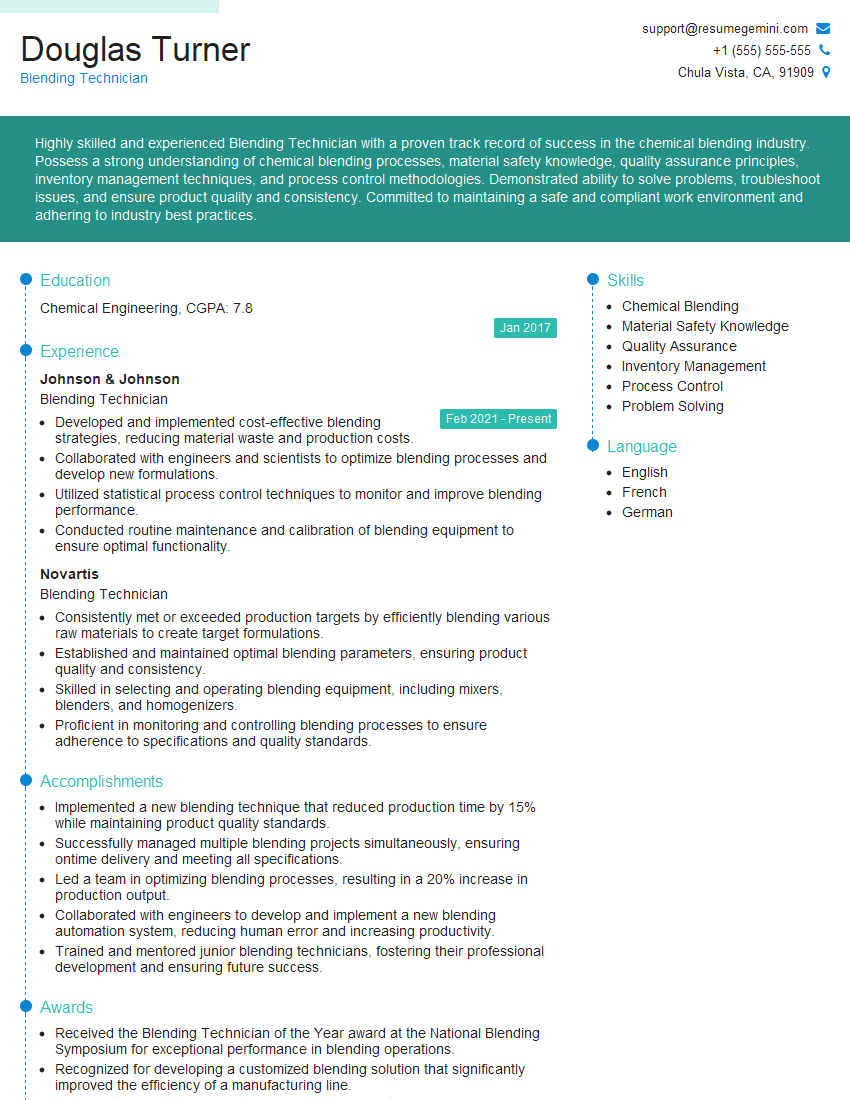

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blending Technician

1. What are the key responsibilities of a Blending Technician?

As a Blending Technician, I would be responsible for:

- Operating blending equipment to mix raw materials according to specified formulations.

- Maintaining and calibrating blending equipment to ensure accurate and efficient operation.

2. Can you describe the steps involved in the blending process?

Blending Process Steps

- Receiving raw materials and verifying their quality.

- Preparing blending equipment and ensuring its cleanliness.

- Mixing raw materials according to specified formulations and proportions.

- Monitoring the blending process and making adjustments as needed.

- Sampling and testing blended materials to ensure they meet specifications.

Quality Control and Assurance

- Adhering to established quality control procedures.

- Documenting all blending operations and maintaining records.

- Identifying and resolving any blending issues promptly.

3. Explain how you would troubleshoot a blending issue.

In the event of a blending issue, I would follow a systematic troubleshooting process:

- Identify the specific problem or deviation from specifications.

- Check the blending equipment for any malfunctions or calibration issues.

- Review the blending formulation and verify that all raw materials were added correctly.

- Inspect the raw materials for any contamination or variations in quality.

- Adjust the blending parameters or make necessary corrections based on my findings.

- Repeat the blending process and monitor the results closely.

4. What are some of the common safety hazards in a blending facility, and how can they be mitigated?

Common safety hazards in a blending facility include:

- Exposure to hazardous chemicals or fumes

- Moving machinery and equipment

- Electrical hazards

- Slips, trips, and falls

To mitigate these hazards, it is important to:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and respirators.

- Follow established safety protocols and procedures.

- Keep the work area clean and organized.

- Inspect equipment regularly and report any potential hazards.

- Receive proper training and stay updated on safety regulations.

5. How would you handle a situation where you need to blend a new and unfamiliar material?

When blending a new and unfamiliar material, I would take the following steps:

- Review the material safety data sheet (MSDS) to understand its properties and potential hazards.

- Consult with a supervisor or technical expert for guidance and advice.

- Start with a small-scale trial blend to determine the optimal blending parameters.

- Monitor the blending process closely and make adjustments as needed.

- Document the process and results for future reference.

6. What is your experience with blending different types of materials?

I have experience blending a wide range of materials, including:

- Chemicals

- Polymers

- Minerals

- Additives

I understand the different properties and characteristics of these materials and how to blend them effectively to achieve the desired results.

7. How do you ensure the quality and consistency of blended materials?

To ensure the quality and consistency of blended materials, I follow a rigorous quality control process that includes:

- Verifying the quality of raw materials

- Calibrating blending equipment regularly

- Monitoring the blending process

- Sampling and testing blended materials

- Documenting all blending operations

- Taking corrective actions when necessary

8. What are some of the challenges you have faced in your previous blending roles and how did you overcome them?

One challenge I faced was blending a new type of material that had unique properties. To overcome this, I consulted with technical experts and conducted several trial blends to determine the optimal blending parameters.

Another challenge was meeting tight production deadlines while maintaining quality standards. To address this, I worked closely with the production team to develop a detailed production schedule and implemented efficient blending techniques to maximize productivity.

9. Why are you interested in working as a Blending Technician in our company?

I am interested in working as a Blending Technician in your company because I am impressed by your commitment to quality and innovation. I believe that my skills and experience would be a valuable asset to your team, and I am eager to contribute to the success of your company.

10. What are your salary expectations?

My salary expectations are commensurate with my experience and qualifications. I am open to discussing a salary range that is fair and competitive for the position and industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blending Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blending Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blending Technician is responsible for ensuring the precise blending of raw materials to create specific product formulations. Their key responsibilities include:

1. Blending and Mixing

Operates and maintains blending equipment to mix and blend raw materials according to specified formulas and procedures.

- Calibrates and maintains blending machines.

- Monitors blending process to ensure proper mixing and consistency.

2. Quality Control

Conducts quality control checks on blended products to ensure they meet specifications.

- Inspects and tests samples of blended products.

- Records and maintains quality control data.

3. Equipment Maintenance

Performs routine maintenance and repairs on blending equipment.

- Cleans and lubricates equipment.

- Troubleshoots and repairs minor equipment malfunctions.

4. Safety and Compliance

Adheres to all safety regulations and procedures related to blending operations.

- Wears appropriate personal protective equipment.

- Follows established safety protocols.

- Maintains a clean and organized work area.

Interview Tips

To ace an interview for a Blending Technician position, candidates should prepare by:

1. Researching the Company and Role

Learn about the company’s products, industry, and values. Understand the specific responsibilities of the Blending Technician role and how it fits within the organization.

- Visit the company website and social media pages.

- Read industry publications to gain insights into the company’s market position.

2. Practicing Technical Skills

Review your knowledge of blending techniques, quality control procedures, and equipment maintenance. Be prepared to discuss your experience in operating and troubleshooting blending equipment.

- Describe a specific project where you successfully blended materials to meet precise specifications.

- Explain your understanding of quality control testing methods for blended products.

3. Demonstrating Safety Awareness

Emphasize your commitment to safety and compliance. Describe your experience in following safety protocols and maintaining a clean and organized work environment.

- Highlight your knowledge of relevant safety regulations and standards.

- Provide examples of how you have proactively identified and addressed safety hazards.

4. Preparing Questions

Preparing thoughtful questions for the interviewer shows your engagement and interest in the role. Ask questions about the company’s growth plans, the specific challenges of the Blending Technician position, or any opportunities for professional development.

- Inquire about the company’s commitment to quality control and innovation.

- Ask about the potential for career advancement within the organization.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blending Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blending Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.