Are you gearing up for an interview for a Blindstitch Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blindstitch Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

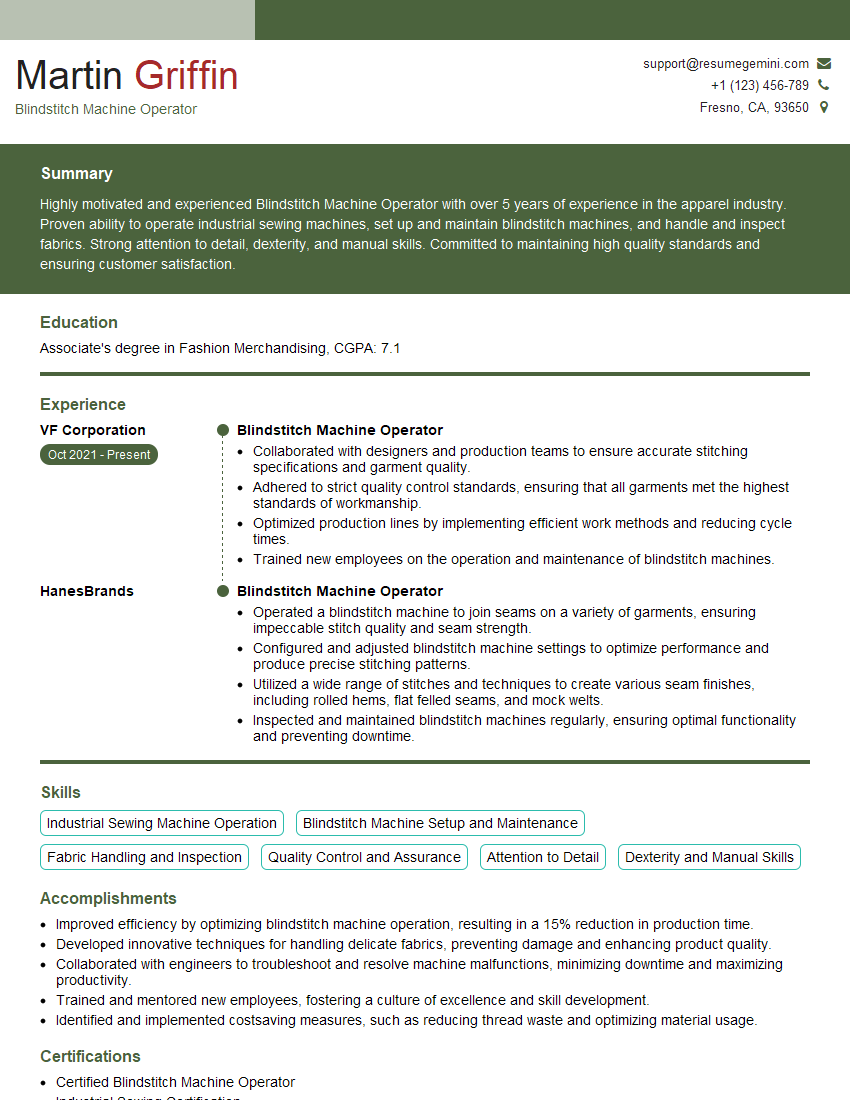

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blindstitch Machine Operator

1. Describe the key functions and responsibilities of a Blindstitch Machine Operator?

Key Functions:

- Operate blindstitch machines to sew hidden seams on garments and other textile products.

- Ensure that the machines are properly set up and maintained to optimize their performance.

- Inspect finished products for quality and accuracy, identifying and correcting any defects.

Responsibilities:

- Follow work orders and specifications to produce high-quality products.

- Maintain a clean and organized work area to promote safety and efficiency.

- Collaborate with other team members to achieve production goals.

2. Explain the different types of fabrics that can be sewn using a blindstitch machine?

- Lightweight fabrics such as silk, chiffon, and lace.

- Medium-weight fabrics such as cotton, linen, and denim.

- Heavyweight fabrics such as canvas, leather, and upholstery.

- Stretch fabrics such as spandex, lycra, and jersey.

3. What are the common problems encountered when operating a blindstitch machine and how do you resolve them?

- Skipped stitches: Adjust tension settings or replace the needle.

- Broken threads: Check for burrs on the machine parts, replace the thread, or adjust tension.

- Puckering: Ensure the fabric is evenly fed into the machine and adjust tension settings.

- Birdnesting: Remove the thread from the machine, clean the bobbin case, and rethread.

4. Describe the safety precautions that should be followed while operating a blindstitch machine?

- Wear appropriate safety gear such as gloves and eye protection.

- Keep hands away from the needle and moving parts.

- Use the safety guard provided with the machine.

- Unplug the machine before performing maintenance or repairs.

5. Explain how you ensure the quality of the finished products produced using a blindstitch machine?

- Inspect the seams for proper stitch length, tension, and alignment.

- Check for any loose threads or skipped stitches.

- Ensure that the seam is hidden and does not compromise the appearance of the garment.

- Follow quality control procedures and specifications established by the company.

6. What are the different maintenance tasks that need to be performed on a blindstitch machine?

- Clean and lubricate the machine regularly.

- Inspect and replace worn or damaged parts, such as needles, bobbins, and belts.

- Adjust tension settings and timing as needed.

- Perform scheduled maintenance according to the manufacturer’s recommendations.

7. Describe your experience in troubleshooting and repairing blindstitch machines?

- Diagnose common problems and identify the underlying causes.

- Perform basic repairs such as needle replacement, thread tension adjustment, and bobbin winding.

- Collaborate with mechanics for more complex repairs.

8. What are the factors that affect the stitch quality of a blindstitch machine?

- Thread quality and tension

- Needle size and shape

- Fabric type and thickness

- Machine settings and maintenance

- Operator skill and experience

9. Describe the different stitches that can be produced using a blindstitch machine?

- Straight stitch

- Zigzag stitch

- Overlock stitch

- Topstitch

- Blind hem stitch

10. What are the latest advancements in blindstitch machine technology?

- Computerized machines with programmable stitch patterns

- Automated thread cutters

- Laser guides for increased precision

- Eco-friendly features such as reduced energy consumption

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blindstitch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blindstitch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blindstitch Machine Operator is responsible for operating blindstitch machines to sew various types of fabrics, primarily for the creation of garments, upholstery, and other textile products. Here are the key job responsibilities:

1. Machine Operation and Maintenance

Operate blindstitch machines to stitch fabrics together with precision and accuracy.

- Set up and configure machines according to specific production requirements.

- Monitor machine operation and make necessary adjustments to ensure smooth functioning.

- Perform routine maintenance on machines, such as cleaning, oiling, and minor repairs.

2. Fabric Handling and Inspection

Handle and inspect fabrics prior to stitching, ensuring proper preparation for the sewing process.

- Inspect fabrics for defects, stains, or any other issues that may affect sewing quality.

- Prepare fabrics by folding, marking, or cutting as required for stitching.

- Identify and select appropriate thread and needles for different fabrics and stitching applications.

3. Quality Control and Troubleshooting

Inspect and assess the quality of stitched products, identifying and addressing any defects or errors.

- Check stitched seams for accuracy, strength, and overall appearance.

- Identify and resolve sewing problems, such as thread breakage, skipped stitches, or fabric puckering.

- Maintain high standards of quality and accuracy in all production operations.

4. Production Management and Efficiency

Meet production targets by managing time and resources effectively, ensuring timely completion of orders.

- Coordinate with other team members to ensure a smooth workflow.

- Monitor production processes to identify areas for improvement and increase efficiency.

- Participate in continuous improvement initiatives to enhance productivity and quality.

Interview Tips

Preparing thoroughly for an interview is crucial to making a positive impression and increasing your chances of landing the job. Here are some interview tips and preparation hacks:

1. Research the Company and Position

Thoroughly research the company and the specific Blindstitch Machine Operator position you are applying for.

- Visit the company website to learn about their history, products or services, and culture.

- Review the job description carefully to understand the specific responsibilities, qualifications, and requirements.

2. Practice Your Answers

Prepare and practice your answers to common interview questions related to your skills, experience, and suitability for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

- Focus on highlighting your relevant skills and experiences that match the job requirements.

3. Be Prepared to Discuss Your Skills and Experience

Emphasize your proficiency in blindstitch machine operation, fabric handling, quality control, and production management.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Highlight any additional skills or certifications that make you a suitable candidate for the role.

4. Ask Thoughtful Questions

Prepare a list of thoughtful questions to ask the interviewer, demonstrating your interest in the company and the position.

- Ask about the company’s growth plans, industry trends, or specific projects related to the role.

- Inquire about the company’s training and development opportunities for employees.

5. Dress Professionally and Arrive Punctually

Dress professionally for the interview and arrive on time, showing respect for the interviewer and the company.

- Choose attire that is appropriate for the industry and company culture.

- Allow ample time for travel and unexpected delays to ensure you arrive punctually for the interview.

Next Step:

Now that you’re armed with the knowledge of Blindstitch Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Blindstitch Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini