Are you gearing up for a career in Block Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Block Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

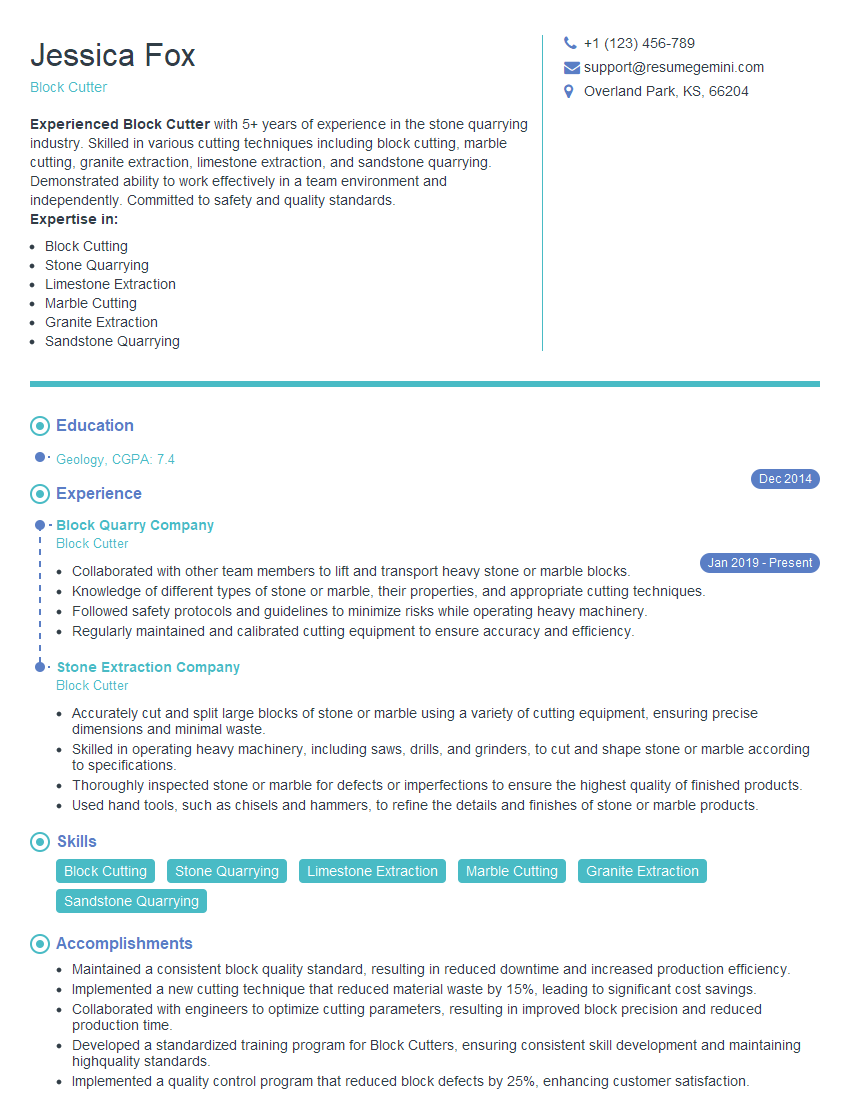

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Cutter

1. What are the key responsibilities of a Block Cutter?

As a Block Cutter, my primary responsibilities would include:

- Receiving and interpreting cutting orders and specifications

- Selecting and setting up appropriate cutting equipment, such as saws, presses, and cutters

- Positioning and securing blocks of stone or material for cutting

- Operating cutting machinery accurately and efficiently to achieve desired shapes and dimensions

- Inspecting cut pieces for quality and accuracy, and making any necessary adjustments

2. Describe the different types of cutting techniques used in block cutting and their applications.

Diamond Sawing:

- Used for precise and intricate cuts in hard materials like granite and marble

- Involves using a diamond-tipped blade and water as a coolant

Wire Sawing:

- Employed for large-scale cutting of blocks from quarries or mines

- Utilizes a continuous wire coated with diamond particles

Gang Sawing:

- Suitable for cutting multiple blocks of stone simultaneously

- Consists of a series of diamond-tipped blades mounted on a frame

3. How do you ensure the accuracy and precision of your cuts?

To ensure accuracy and precision in my cuts, I follow these key practices:

- Carefully reviewing cutting orders and specifications

- Using precision measuring tools and templates for marking and alignment

- Setting up cutting equipment accurately and making necessary adjustments

- Emphasizing attention to detail throughout the cutting process

- Conducting regular inspections and making adjustments to ensure ongoing accuracy

4. What are the safety precautions you observe while operating cutting machinery?

Safety is paramount in my work as a Block Cutter. I adhere to the following precautions:

- Wearing appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection

- Ensuring proper ventilation and dust control to minimize exposure to harmful particles

- Maintaining a clean and organized work area to prevent tripping hazards

- Following established operating procedures and lockout/tagout protocols

- Undergoing regular safety training and staying up-to-date on industry best practices

5. How do you handle variations in the hardness and texture of different stone materials?

Adjusting to varying stone characteristics is crucial in block cutting. I employ the following strategies:

- Assessing the hardness and texture of the stone before cutting

- Selecting appropriate cutting blades and techniques based on the material’s properties

- Adjusting cutting parameters such as speed and feed rate to optimize efficiency and minimize wear on equipment

- Consulting with experienced colleagues or supervisors when encountering particularly challenging materials

6. What techniques do you use to minimize waste and optimize material utilization?

Reducing waste and maximizing material utilization is an important aspect of block cutting:

- Planning cutting sequences to minimize off-cuts and unusable pieces

- Utilizing nesting techniques to arrange cuts efficiently within a block

- Exploring options for reusing or repurposing cut-offs for other applications

- Collaborating with other departments to identify potential uses for waste materials

7. How do you stay updated on the latest advancements in block cutting technology?

To keep abreast of industry advancements, I engage in these practices:

- Attending industry conferences, workshops, and trade shows

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Seeking opportunities for professional development and training

8. What is your approach to troubleshooting and resolving issues that arise during the cutting process?

When faced with issues during cutting, I follow a systematic approach:

- Identifying the problem and potential causes

- Inspecting equipment and verifying settings

- Reviewing cutting parameters and making adjustments as needed

- Consulting with colleagues or supervisors for assistance and guidance

- Documenting the problem and resolution for future reference

9. How do you prioritize and manage your workload when working on multiple cutting projects simultaneously?

Managing multiple projects requires effective prioritization and time management:

- Reviewing cutting orders and deadlines to establish priorities

- Planning a work schedule that optimizes resource allocation

- Delegating tasks to team members when feasible

- Regularly assessing progress and making adjustments as needed

- Communicating effectively with colleagues and supervisors to ensure coordination

10. Describe a challenging or unusual cutting project you encountered and how you successfully completed it.

In a recent project, I encountered a block of granite with unusually hard inclusions. To overcome this challenge, I:

- Assessed the material characteristics and selected a specialized diamond blade

- Adjusted cutting parameters to minimize chipping and breakage

- Utilized a combination of saw and wire cutting techniques

- Collaborated with the project engineer to develop an optimized cutting plan

- Through careful execution and attention to detail, I successfully completed the project, meeting both quality and deadline requirements

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Cutters perform a crucial task in various industries, including construction, mining, and stoneworking. Their primary responsibilities involve cutting and shaping raw materials into blocks or other desired forms using specialized machinery.

1. Block Cutting and Shaping

Their key role is to operate high-powered saws, such as diamond-wire saws or gang saws, to cut and shape raw materials, including rock, concrete, and stone, into specific block shapes and dimensions.

- Accurately following cutting plans and specifications to ensure precise dimensions and angles

- Adjusting machine settings to optimize cutting efficiency and minimize waste

2. Equipment Operation and Maintenance

Block Cutters are responsible for the safe and proper operation of heavy machinery. They perform regular maintenance tasks to ensure optimal performance, including:

- Lubricating and inspecting equipment to prevent breakdowns

- Replacing worn or damaged parts to maintain machine reliability

3. Material Handling

Moving and handling heavy blocks requires physical strength and proper techniques. Block Cutters are involved in:

- Loading and unloading blocks using cranes or forklifts

- Stacking and storing blocks safely to prevent damage

4. Safety Compliance

Working with heavy machinery and sharp tools poses safety risks. Block Cutters must adhere to strict safety protocols, including:

- Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and helmets

- Following established operating procedures to minimize accidents

Interview Tips

Preparing for a job interview is essential for showcasing your skills and making a positive impression. Here are some key tips to help candidates ace their Block Cutter interview:

1. Research the Industry and Company

Familiarize yourself with the construction, mining, or stoneworking industry and the specific company you’re applying to. This demonstrates your interest and understanding of the role.

- Visit company websites and LinkedIn pages to learn about their operations, values, and projects.

- Read industry publications and articles to stay up-to-date on trends and technologies.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers that highlight your relevant skills and experience. Consider questions such as:

- “Tell us about your experience operating heavy machinery, specifically diamond-wire saws.”

- “Describe a time when you ensured safety while working with cutting and shaping equipment.”

3. Showcase Your Physical Capabilities

Block Cutting is a physically demanding job. Emphasize your strength, endurance, and ability to handle heavy lifting and physical exertion during the interview.

- Provide examples of previous work or personal experiences that demonstrate your physical fitness.

- Be prepared to discuss your ability to work effectively in outdoor conditions, including extreme temperatures or inclement weather.

4. Highlight Your Safety Awareness

Safety is paramount in the Block Cutting industry. Emphasize your commitment to following safety protocols, wearing PPE, and maintaining a safe work environment.

- Describe any safety certifications or training you have completed.

- Share specific examples of how you have identified and mitigated potential safety hazards in previous work situations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Block Cutter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!