Are you gearing up for a career in Block Making Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Block Making Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

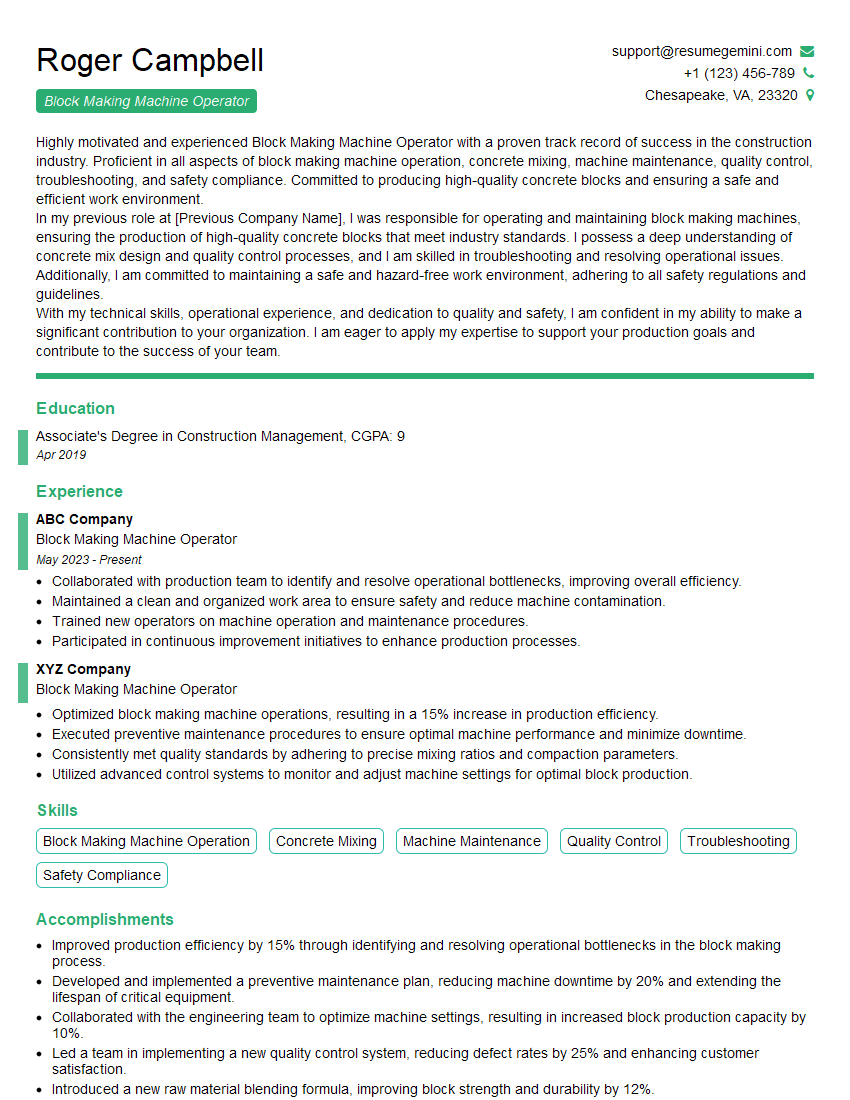

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Making Machine Operator

1. What is the most important factor which affects the quality of the block produced by the Block making machine?

Answer:

- The moisture content of the raw material

- The air entrapped in the raw material

- The curing process

- The type of raw material used

2. List down 5 common problems associated with Block making machines and how do you troubleshoot them?

a. Uneven block size

- Check if the mold is properly aligned and secured

- Check if the raw material is evenly distributed in the mold

- Check if the machine is level

b. Cracks in the blocks

- Check if the curing process is being followed properly

- Check if the raw material is of good quality

- Check if the machine is properly calibrated

c. Low production output

- Check if the machine is properly maintained and lubricated

- Check if the raw material is being fed properly

- Check if the machine is operating at the correct speed

d. Machine breakdowns

- Check if the machine is properly maintained and lubricated

- Check if the machine is being operated properly

- Call a qualified technician to repair the machine

e. Safety hazards

- Make sure that the machine is properly guarded

- Make sure that the operator is properly trained

- Follow all safety procedures

3. What are the different types of Block making machines available in the market?

Answer:

- Hydraulic block making machine

- Mechanical block making machine

- Manual block making machine

- Automatic block making machine

4. What are the advantages of using a Block making machine over manual labor?

Answer:

- Higher production output

- Lower labor costs

- Improved quality of blocks

- Reduced waste

- Increased safety

5. What are the key maintenance tasks that need to be performed on a Block making machine?

Answer:

- Regular cleaning and lubrication

- Inspection of all moving parts

- Tightening of all bolts and nuts

- Replacement of worn or damaged parts

- Calibration of the machine

6. What are the safety precautions that need to be taken when operating a Block making machine?

Answer:

- Make sure that the machine is properly guarded

- Make sure that the operator is properly trained

- Wear appropriate safety gear

- Follow all safety procedures

7. What is the role of the Block making machine operator?

Answer:

- Operate the machine to produce blocks

- Monitor the machine to ensure that it is operating properly

- Perform basic maintenance on the machine

- Follow all safety procedures

8. What are the skills and qualifications required to be a Block making machine operator?

Answer:

- High school diploma or equivalent

- Experience in operating machinery

- Knowledge of block making process

- Strong work ethic

- Ability to work independently

9. What is the career path for a Block making machine operator?

Answer:

- Block making machine operator

- Block making machine supervisor

- Block making plant manager

10. What are the challenges of being a Block making machine operator?

Answer:

- Working in a dusty and noisy environment

- Operating heavy machinery

- Meeting production targets

- Working long hours

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block making machine operators are in charge of operating machinery that produces concrete blocks. Their duties involve ensuring that the machine is running smoothly, monitoring the production process, and making adjustments as needed. This involves working with both manual and automated systems, and requires a high level of attention to detail and mechanical aptitude. These operators must be able to work both independently and as part of a team, and must have a strong understanding of the block making process.

1. Operating the Block Making Machine

Operators are tasked with setting up and operating the block making machine. This involves loading raw materials into the machine, such as cement, sand, and aggregate. They must also adjust the machine’s settings to ensure that the blocks are produced to the correct specifications. Operators must be able to troubleshoot any problems that may occur with the machine, and make repairs as needed.

2. Monitoring the Production Process

Operators are responsible for monitoring the production process to ensure that the blocks are being produced to the correct quality and quantity. They must check the blocks for defects, and make adjustments to the machine as needed. Operators must also keep records of the production process, and report any problems to their supervisors.

3. Maintaining the Block Making Machine

Operators are responsible for maintaining the block making machine. This involves cleaning and lubricating the machine, and making minor repairs as needed. Operators must also keep the machine in good working order, and report any major repairs to their supervisors.

4. Working as Part of a Team

Operators often work as part of a team. They must be able to communicate effectively with other operators, and work together to ensure that the production process runs smoothly. Operators must also be able to work independently, and take initiative to solve problems.

Interview Tips

Preparing for an interview for a block making machine operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are some tips to help you ace your interview:

1. Research the Company

Before your interview, take some time to learn about the company. Visit their website, read their annual reports, and check out their social media pages. This will give you a better understanding of the company’s culture, values, and products. By being prepared, you’ll be better able to answer questions about why you’re interested in working for the company and how your skills and experience align with their needs.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions ahead of time so that you can deliver your responses confidently and succinctly. When answering, it is important to focus on your skills, experience, and qualifications; be sure to highlight how they relate to the job requirements. You should also be prepared to discuss your strengths and weaknesses. Be honest about your weaknesses, but focus on how you’re working to improve them.

3. Be Prepared to Ask Questions

At the end of the interview, you will likely be given an opportunity to ask the interviewer questions. This is a great way to show your interest in the position and the company. It also gives you a chance to learn more about the job and the company culture. Some good questions to ask include: “What are the biggest challenges facing the company right now?”; “What are the company’s plans for the future?”; and “What is the company culture like?”

4. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. Make an effort to dress in clean, wrinkle-free clothing that conveys a professional image. You should also arrive for your interview on time and be well-groomed.

5. Be Confident

Confidence is key in any interview. Believe in yourself and your abilities. If you don’t believe in yourself, why should the interviewer? Maintain eye contact, speak clearly and confidently, and use positive body language. A positive attitude can do wonders in making a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Block Making Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!