Feeling lost in a sea of interview questions? Landed that dream interview for Block Out Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Block Out Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

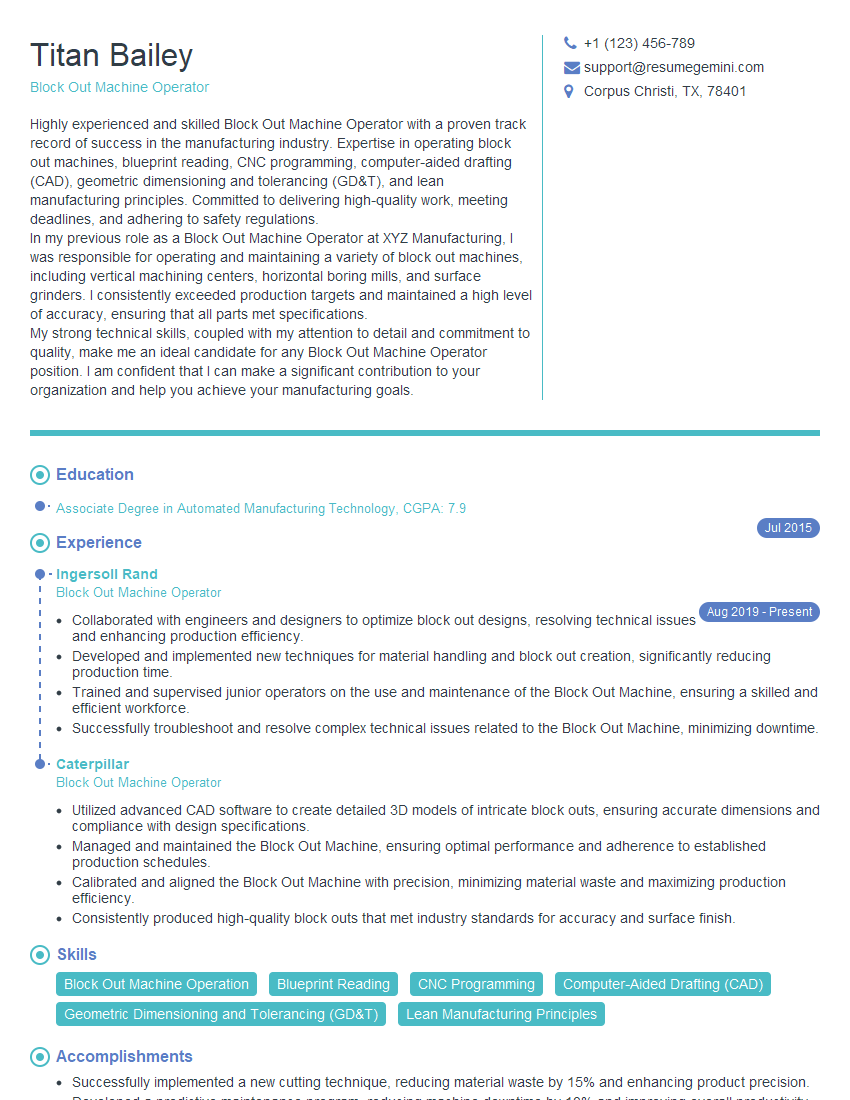

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Out Machine Operator

1. What are the key responsibilities of a Block Out Machine Operator?

• Set up and operate block out machine to cut and shape blocks of concrete or other materials to specified dimensions and tolerances.

• Monitor machine operation and make adjustments as needed to ensure accurate cutting and shaping.

• Inspect finished blocks for quality and accuracy.

• Clean and maintain block out machine and work area.

• Follow safety protocols and procedures.

2. What are the safety protocols that you must follow when operating a block out machine?

Personal Protective Equipment (PPE)

- Wear safety glasses.

- Wear gloves.

- Wear earplugs or earmuffs.

- Wear a hard hat.

Machine Safety

- Ensure that the machine is properly guarded.

- Never operate the machine if it is not in good working order.

- Keep your hands away from the cutting blade.

- Be aware of the location of the emergency stop button.

3. How do you ensure that the finished blocks meet the specified dimensions and tolerances?

• Use precision measuring tools to set up the machine.

• Monitor the machine operation and make adjustments as needed.

• Inspect finished blocks for quality and accuracy.

• Recalibrate the machine regularly.

4. What are some of the common problems that you may encounter when operating a block out machine?

• The machine may not be cutting accurately.

• The machine may be vibrating excessively.

• The machine may be making strange noises.

• The machine may be leaking fluid.

• The machine may be overheating.

5. How do you troubleshoot and resolve these problems?

• Refer to the machine’s manual.

• Check the machine’s electrical connections.

• Check the machine’s hydraulic system.

• Check the machine’s cutting blade.

• Contact the machine’s manufacturer.

6. What are some of the maintenance tasks that you perform on a regular basis?

• Clean the machine.

• Lubricate the machine.

• Inspect the machine for wear and tear.

• Calibrate the machine.

• Replace worn parts.

7. What are some of the skills and qualities that are important for a successful Block Out Machine Operator?

- Attention to detail.

- Mechanical aptitude.

- Problem-solving skills.

- Safety consciousness.

- Teamwork skills.

8. What is your experience with block out machines?

I have been operating block out machines for the past 5 years.

I have experience with a variety of block out machines, including manual, semi-automatic, and fully automatic machines.

I have a strong understanding of the principles of block out machine operation and maintenance.

I am proficient in setting up, operating, and troubleshooting block out machines.

I have a proven track record of producing high-quality blocks that meet the specified dimensions and tolerances.

9. What are your strengths and weaknesses as a Block Out Machine Operator?

Strengths

- I am a highly skilled and experienced Block Out Machine Operator.

- I have a strong attention to detail and a commitment to quality.

- I am a quick learner and I am always willing to take on new challenges.

- I am a team player and I am always willing to help out my colleagues.

Weaknesses

- I can be a bit of a perfectionist at times.

- I am not always the most patient person.

10. Why should we hire you as a Block Out Machine Operator?

I am a highly skilled and experienced Block Out Machine Operator with a strong commitment to quality and safety.

I am confident that I can make a significant contribution to your company.

I am a hard worker and I am always willing to go the extra mile.

I am a team player and I am always willing to help out my colleagues.

I am confident that I can be a valuable asset to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Out Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Out Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Out Machine Operators are responsible for operating and maintaining a variety of block making machines. They are also responsible for ensuring that the products produced by the machines meet the company’s quality standards.

1. Prepare and maintain block making machines

Block Out Machine Operators typically begin their day by preparing the block making machines for use. This involves checking the machines for any damages or malfunctions, and making any necessary adjustments.

- Conduct regular maintenance and repairs

- Monitor and adjust machine settings

2. Load raw materials into the machine

Once the machines are ready for use, Block Out Machine Operators load the raw materials into the machine. The type of raw materials used will vary depending on the type of blocks being produced.

- Ensure that the raw materials meet the company’s specifications

- Feed the raw materials into the machine evenly

3. Operate the machine

Once the raw materials have been loaded into the machine, Block Out Machine Operators start the machine and monitor its operation.

- Control the speed and pressure of the machine

- Monitor the machine for any problems

4. Unload the finished products from the machine

Once the blocks have been formed, Block Out Machine Operators unload the finished products from the machine. They then inspect the products for any defects, and stack them on pallets for storage or shipment.

- Unload the finished products safely and efficiently

- Inspect the products for any defects

Interview Tips

To help candidates ace the interview for a Block Out Machine Operator position, ensure that you have a clear understanding of the key job responsibilities. You should also be prepared to answer questions about your experience with block making machines, as well as your knowledge of the industry.

1. Research the company and the position

Before the interview, take some time to research the company and the position. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read articles about the company and the industry

- Talk to people you know who work for the company

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can feel confident and prepared during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with block making machines?

- What is your knowledge of the industry?

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Arrive a few minutes early for your interview

- Be polite and respectful to everyone you meet

4. Be yourself and be confident

It is important to be yourself and be confident during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest and authentic

- Be positive and enthusiastic

- Believe in yourself and your abilities

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Block Out Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Block Out Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.