Are you gearing up for a career in Block Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Block Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

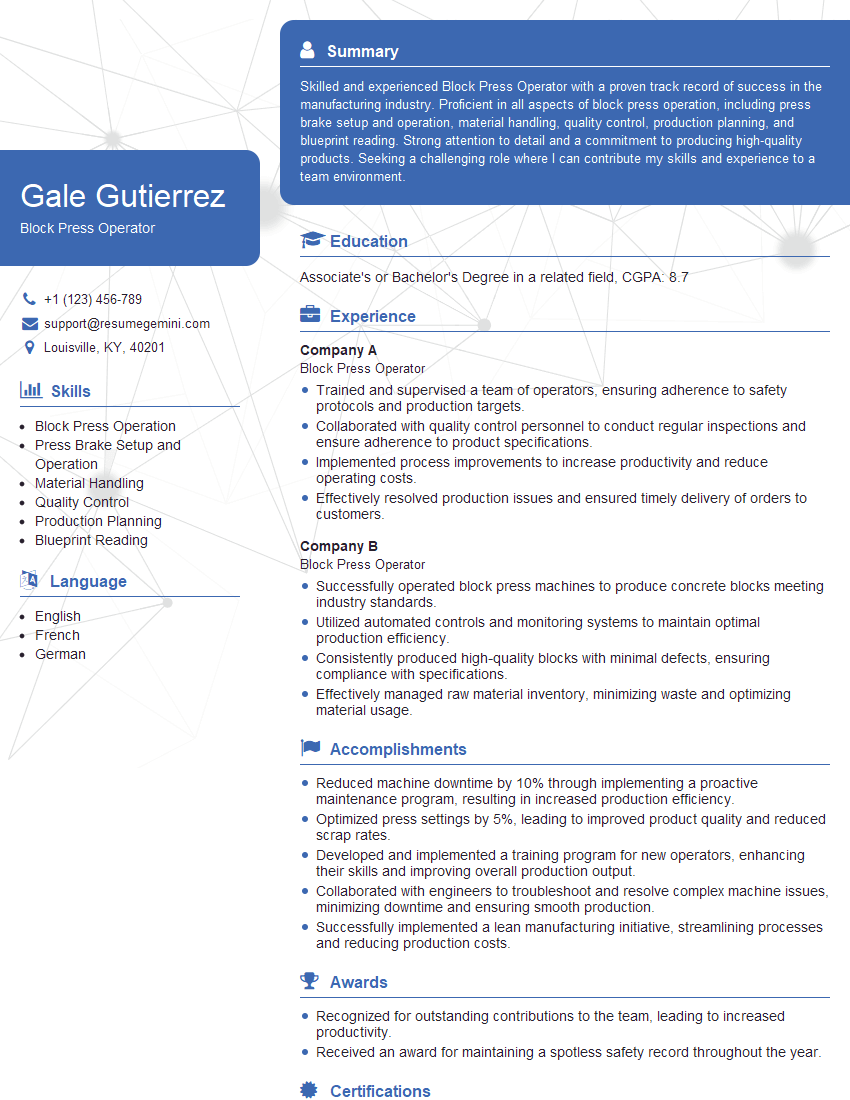

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Press Operator

1. Explain the working principle of a block press machine.

The block press machine operates based on the following principles:

- Hydraulic Pressure: The machine utilizes hydraulic pressure to apply force onto the mold, compacting the material inside.

- Mold and Platen: A mold defines the shape of the block, and the platen exerts pressure on the mold.

- Material Filling: The mold is filled with the desired material, such as concrete or fly ash.

- Compaction: Hydraulic pressure is applied to the platen, compressing the material within the mold.

- Ejection: Once compacted, the mold is opened, and the finished block is ejected.

2. Describe the types of materials that can be processed in a block press machine.

- Concrete: Widely used for paving blocks, bricks, and construction elements.

- Fly Ash: A byproduct of coal combustion, commonly used in lightweight blocks.

- Sand: Used for producing sand blocks for landscaping and construction.

- Gypsum: Creates gypsum blocks for interior partitions and fireproofing.

- Recycled Materials: Some machines can process recycled materials like glass or plastic.

3. What are the key factors that affect the quality of the finished blocks?

- Material Properties: The strength, consistency, and moisture content of the material.

- Pressing Pressure: The amount of pressure applied during compaction.

- Mold Design: The shape and dimensions of the mold.

- Curing Process: The conditions under which the blocks are allowed to harden.

- Maintenance and Calibration: Regular maintenance and calibration of the machine.

4. How do you maintain a block press machine?

- Regular Cleaning: Remove any debris or buildup from the mold, platen, and other components.

- Hydraulic System Maintenance: Check hydraulic fluid levels, replace filters, and maintain proper pressure.

- Lubrication: Lubricate moving parts to reduce wear and ensure smooth operation.

- Electrical System Inspection: Ensure proper wiring, connections, and electrical safety.

- Calibration: Regularly calibrate the machine to maintain accuracy and consistency.

5. What troubleshooting steps would you take if the machine is not producing blocks to the desired specifications?

- Check Material Quality: Verify that the material meets the required specifications.

- Adjust Pressing Pressure: Increase or decrease pressure to achieve the desired compaction.

- Inspect Mold: Ensure the mold is clean, undamaged, and properly installed.

- Review Curing Process: Adjust curing time or conditions to optimize block strength.

- Contact Manufacturer: Consult the machine manufacturer if the issue persists.

6. What safety precautions should be observed when operating a block press machine?

- Wear Protective Gear: Use gloves, safety glasses, and earplugs.

- Follow Lockout/Tagout Procedures: Isolate the machine before performing maintenance.

- Stay Clear of Moving Parts: Avoid contact with hydraulics, platens, or moving components.

- Monitor Pressure Gauges: Ensure hydraulic pressure is within safe limits.

- Be Aware of Surroundings: Pay attention to potential hazards and keep the work area clear.

7. How do you determine the optimal pressing pressure for a given material?

- Material Testing: Conduct tests on sample materials to determine the ideal pressure.

- Manufacturer’s Recommendations: Refer to the manufacturer’s specifications for guidance.

- Trial and Error: Adjust pressure incrementally and observe the resulting blocks.

- Experience and Judgment: Utilize experience and knowledge of materials to estimate the appropriate pressure.

8. What is the importance of proper curing for the strength and durability of the blocks?

- Strength Development: Curing allows the material to hydrate and develop strength.

- Reduced Shrinkage: Proper curing minimizes shrinkage and cracking.

- Improved Durability: Cured blocks are more resistant to moisture, wear, and weathering.

- Moisture Control: Curing prevents moisture loss, ensuring the blocks reach their full potential strength.

9. Describe the process of setting up and calibrating a block press machine.

- Installation: Place the machine on a level surface and connect utilities.

- Mold Installation: Install the mold according to the manufacturer’s instructions.

- Pressure Calibration: Adjust the hydraulic pressure to the desired level using a pressure gauge.

- Test Run: Perform a test run with sample material to ensure proper operation.

- Fine-tuning: Make any necessary adjustments to pressure, mold alignment, or other settings.

10. How would you prioritize your tasks if you were responsible for managing the production of a block press machine?

- Ensuring Machine Uptime: Prioritize maintenance and troubleshooting to keep the machine running smoothly.

- Quality Control: Regularly check block quality and make adjustments as needed.

- Material Management: Monitor material inventory and ensure timely delivery.

- Production Efficiency: Optimize machine settings and processes to maximize output.

- Safety: Maintain a safe work environment and follow all safety protocols.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Press Operators are responsible for operating block presses to shape and mold various materials, such as rubber, plastic, and metal. Their primary duties include:

1. Machine Operation

Operate and maintain block presses, ensuring they are in good working order.

- Monitor pressure, temperature, and other machine settings.

- Adjust machine parameters to achieve desired product quality.

2. Material Handling

Load and unload raw materials and finished products from the press.

- Inspect materials for defects and ensure proper alignment within the press.

- Remove molded products from the press and inspect them for quality.

3. Quality Control

Monitor the production process and ensure that products meet specifications.

- Conduct visual inspections and dimensional measurements.

- Identify and correct any deviations from product standards.

4. Maintenance and Troubleshooting

Perform basic maintenance and troubleshooting on block presses.

- Lubricate machinery and replace worn parts.

- Identify and resolve minor machine malfunctions.

5. Safety and Compliance

Adhere to safety regulations and maintain a clean and organized work area.

- Wear appropriate safety gear, such as gloves and earplugs.

- Follow proper lockout/tagout procedures.

Interview Tips

To ace the interview for a Block Press Operator position, consider the following preparation tips and hacks:

1. Research the Company and Industry

Gather information about the company’s products, services, and industry trends. This will demonstrate your interest in the organization and its business.

- Visit the company’s website and read industry publications.

- Connect with current or former employees on LinkedIn.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating block presses and related machinery. Mention any certifications or training programs that enhance your qualifications.

- Quantify your accomplishments using specific examples.

- Use action verbs to describe your responsibilities, such as “operated,” “maintained,” and “inspected.”

3. Showcase Your Technical Abilities

Demonstrate your understanding of block press operations and troubleshooting techniques. Be prepared to discuss specific scenarios and how you would resolve them.

- Describe a time when you successfully diagnosed and repaired a press malfunction.

- Explain how you ensure product quality and meet specifications.

4. Emphasize Safety and Compliance

Stress your commitment to workplace safety and compliance. Discuss your knowledge of safety regulations and procedures.

- Mention any safety initiatives or awards you have received.

- Provide examples of how you maintain a safe and organized work environment.

5. Be Enthusiastic and Presentable

Show enthusiasm for the position and the company. Dress professionally and arrive on time for the interview.

- Ask thoughtful questions about the role and the company’s culture.

- Follow up with a thank-you note after the interview.

Next Step:

Now that you’re armed with the knowledge of Block Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Block Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini