Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Block Sawyer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

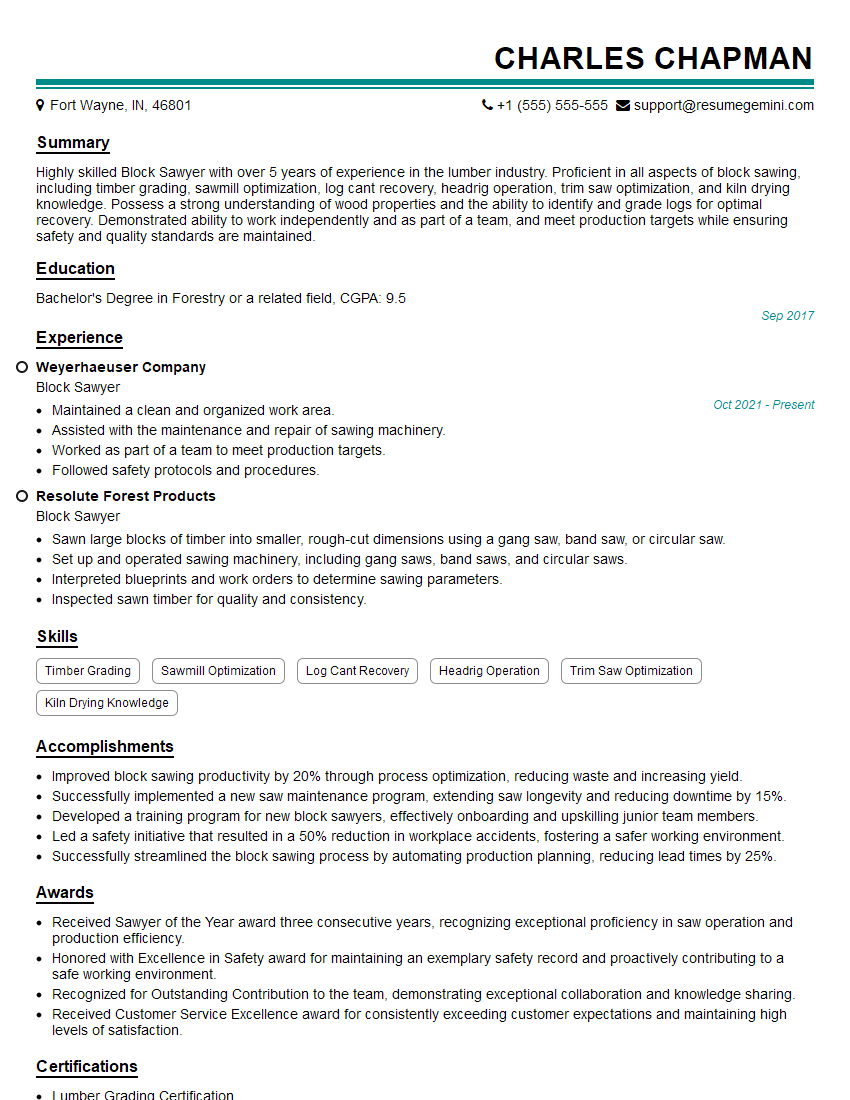

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Sawyer

1. What are the essential steps involved in the block saw process?

The block saw process involves several key steps:

- Mounting the block: The raw block of stone is secured onto a cutting table using clamps or vacuum pads.

- Setting up the saw: The block saw, consisting of a diamond-tipped blade, is positioned and calibrated according to the desired cut dimensions.

- Cutting: The blade is then lowered onto the block and guided through the material, making precise cuts along predefined lines.

- Monitoring and adjusting: Throughout the cutting process, the operator monitors the blade’s progress, adjusts the feed rate and water flow, and ensures that the cuts meet specifications.

- Removing the finished slabs: Once the cutting is complete, the finished slabs are carefully removed from the table and inspected for quality.

2. How do you determine the optimal cutting parameters (blade speed, feed rate, water flow) for different types of stone?

Blade Speed

- Consider the hardness of the stone: Harder stones require lower blade speeds.

- Adjust based on diamond grit size: Finer grits require higher speeds.

Feed Rate

- Balance cutting efficiency and surface quality: Higher feed rates increase efficiency but may compromise surface finish.

- Take into account stone hardness and blade condition.

Water Flow

- Ensures proper cooling and lubrication of the blade.

- Higher water flow rates for harder stones and faster cutting speeds.

3. What are the common troubleshooting techniques for block saws?

Troubleshooting block saws involves addressing various potential issues:

- Blade wear or damage: Monitor blade condition and replace or sharpen as needed.

- Insufficient water flow: Ensure proper water supply and adjust flow rate accordingly.

- Cutting inaccuracies: Check machine calibration, blade alignment, and table stability.

- Excessive vibration or noise: Inspect blade tension, machine bearings, and cutting parameters.

- Electrical faults: Refer to manufacturer’s instructions and contact electrician if necessary.

4. How do you maintain and calibrate block saws to ensure optimal performance?

Regular maintenance and calibration are crucial for block saw performance:

- Blade maintenance: Sharpen or replace blades as needed to maintain sharp cutting edges.

- Table calibration: Ensure the cutting table is level and free of debris.

- Machine inspection: Check for loose components, lubrication, and overall condition.

- Blade alignment: Adjust blade alignment regularly to ensure perpendicular cuts.

- Water system maintenance: Clean and inspect water nozzles and filters.

5. What safety precautions are essential when operating block saws?

Safety is paramount when operating block saws:

- Proper attire: Wear safety glasses, gloves, and ear protection.

- Blade guards: Ensure blade guards are securely in place.

- Water management: Use water to cool the blade and prevent dust inhalation.

- Machine guarding: Keep all moving parts covered and secure.

- Training and supervision: Only trained and authorized personnel should operate block saws.

6. How do you interpret technical drawings and specifications for block saw operations?

Interpreting technical drawings and specifications is essential:

- Drawing review: Study the drawings to understand the required dimensions, tolerances, and cut patterns.

- Specification analysis: Examine the specifications for material properties, cutting parameters, and quality standards.

- Machine setup: Set up the block saw according to the specified parameters.

- Process monitoring: Ensure that the cutting process adheres to the specifications throughout.

7. What software or tools do you use to optimize block saw production?

Various software and tools can enhance block saw production:

- CAD/CAM software: Design and generate cutting patterns.

- Optimization software: Calculate optimal cutting sequences to minimize waste.

- Machine control systems: Automate machine settings and monitor progress.

- Quality control tools: Measure and assess the quality of cut slabs.

8. How do you handle variations in stone quality and hardness during block saw operations?

Variations in stone properties require adjustments:

- Hardness assessment: Determine stone hardness through testing or experience.

- Parameter optimization: Adjust cutting parameters (blade speed, feed rate, water flow) based on stone hardness.

- Blade selection: Choose blades with appropriate diamond grit size and bond type.

- Cutting strategy: Modify cutting patterns or use multiple blades to minimize impact of variations.

9. What techniques do you employ to achieve high surface quality and minimize defects in block saw cuts?

High surface quality is crucial:

- Optimized cutting parameters: Set appropriate feed rates and blade speeds to reduce chipping or scratching.

- Sharp blades: Maintain sharp blades to ensure clean cuts.

- Water management: Adequate water flow cools the blade and prevents heat-induced defects.

- Post-processing: Consider additional finishing processes like polishing or honing to enhance surface appearance.

10. How do you monitor and control the production efficiency of block saw operations?

Efficiency monitoring is essential:

- Production tracking: Record cutting times, material usage, and finished product output.

- Performance analysis: Evaluate production data to identify bottlenecks and areas for improvement.

- Process optimization: Implement changes to enhance efficiency, such as optimizing cutting patterns or automating tasks.

- Equipment maintenance: Regular maintenance ensures minimal downtime and optimal machine performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Sawyer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Sawyer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Sawyers are responsible for operating and maintaining block saws to cut wood into lumber. They must be able to read and interpret blueprints and diagrams, and they must have a strong understanding of the properties of wood. Block Sawyers must also be able to perform basic math and geometry calculations.

1. Operate block saws

Block Sawyers are responsible for operating block saws to cut wood into lumber. They must be able to read and interpret blueprints and diagrams, and they must have a strong understanding of the properties of wood. Block Sawyers must also be able to perform basic math and geometry calculations.

- Set up and adjust block saws according to blueprints and diagrams

- Feed wood into block saws and operate saws to cut wood into lumber

- Monitor block saws during operation and make adjustments as needed

2. Maintain block saws

Block Sawyers are responsible for maintaining block saws to ensure that they are in good working condition. They must be able to identify and troubleshoot problems with block saws, and they must be able to perform basic repairs.

- Lubricate and clean block saws

- Inspect block saws for damage and wear

- Repair or replace damaged parts on block saws

3. Inspect lumber

Block Sawyers are responsible for inspecting lumber to ensure that it meets specifications. They must be able to identify defects in lumber, and they must be able to grade lumber according to quality.

- Inspect lumber for defects such as knots, cracks, and splits

- Grade lumber according to quality

- Reject lumber that does not meet specifications

4. Stack and store lumber

Block Sawyers are responsible for stacking and storing lumber to prevent damage. They must be able to stack lumber in a stable and organized manner, and they must be able to protect lumber from the elements.

- Stack lumber in a stable and organized manner

- Protect lumber from the elements

- Load lumber onto trucks or trailers

Interview Tips

Preparing for a Block Sawyer interview can be daunting, but with the right strategies, you can increase your chances of success. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the specific requirements of the job.

2. Practice your answers to common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Block Sawyer. Be prepared to talk about your experience operating and maintaining block saws, and be sure to highlight any relevant skills that you have, such as your ability to read and interpret blueprints and diagrams.

4. Be enthusiastic and positive

The interviewer will be looking for someone who is enthusiastic about the position and who is positive about their ability to do the job. Be sure to convey your enthusiasm and positivity during your interview, and be confident in your abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Block Sawyer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!