Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Block Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Block Tester so you can tailor your answers to impress potential employers.

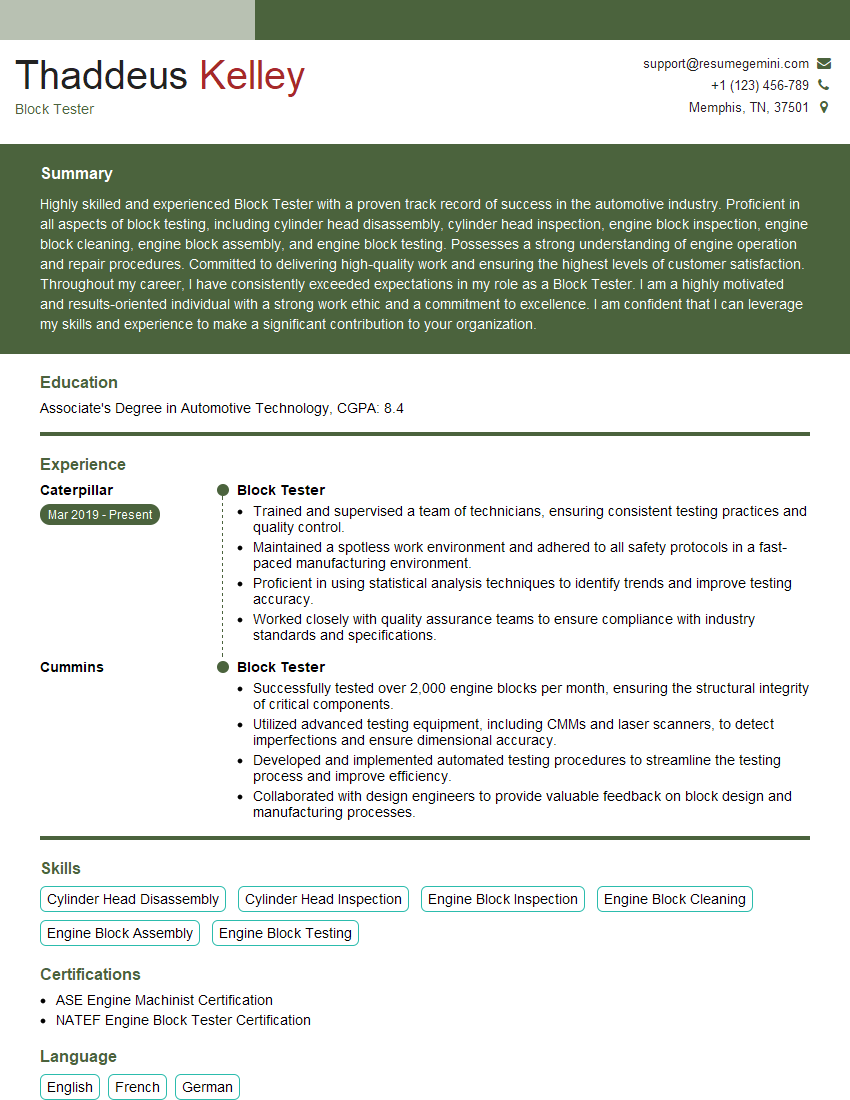

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Block Tester

1. Explain the different types of block tests?

There are three main types of block tests:

- Vacuum test: This test checks for leaks in the block by creating a vacuum inside the block and measuring how long it takes for the vacuum to decay.

- Pressure test: This test checks for leaks in the block by pressurizing the block and measuring how long it takes for the pressure to drop.

- Water jacket test: This test checks for leaks in the block by filling the water jackets with water and looking for leaks.

2. What are the steps involved in performing a vacuum test?

Sub-heading: Safety precautions

- Wear appropriate safety gear, including gloves, safety glasses, and a lab coat.

- Ensure the work area is well-ventilated and free of flammable materials.

Sub-heading: Equipment requirements

- Vacuum pump with a vacuum gauge

- Vacuum chamber

- Adapter plate

Sub-heading: Procedure

- Attach the adapter plate to the block.

- Place the block in the vacuum chamber.

- Start the vacuum pump and create a vacuum inside the chamber.

- Monitor the vacuum gauge and record the time it takes for the vacuum to decay.

3. How would you troubleshoot a failing vacuum test?

Troubleshooting a failing vacuum test involves identifying the source of the leak. This can be done by:

- Checking the vacuum pump and vacuum chamber for leaks.

- Inspecting the block for any visible cracks or damage.

- Using a leak detection spray to identify the location of the leak.

4. What factors can affect the results of a pressure test?

- The type of gas used to pressurize the block.

- The pressure applied to the block.

- The duration of the test.

- The temperature of the block.

5. How do you ensure the accuracy of the equipment used in block testing?

- Calibrate the equipment regularly using traceable standards.

- Follow the manufacturer’s instructions for use and maintenance.

- Establish a quality control program to ensure the accuracy and reliability of the equipment.

6. What are the potential safety hazards associated with block testing?

- High-pressure gas can cause serious injuries if it is released suddenly.

- Vacuum can create a suction hazard that can draw in objects or body parts.

- The use of flammable materials can create a fire hazard.

7. What are the benefits of using a computer-controlled block tester?

- Improved accuracy and repeatability of test results.

- Reduced testing time.

- Automated data collection and analysis.

8. What are the different types of sensors used in block testers?

- Pressure sensors

- Vacuum sensors

- Temperature sensors

9. How do you maintain and calibrate the sensors used in block testers?

- Follow the manufacturer’s maintenance and calibration instructions.

- Use traceable standards to calibrate the sensors regularly.

- Keep the sensors clean and free of debris.

10. What are the quality control procedures used to ensure the reliability of block testing results?

- Establish a quality control program to monitor the accuracy and reliability of the equipment and test procedures.

- Use traceable standards to calibrate the equipment regularly.

- Perform regular audits to ensure that the quality control program is being followed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Block Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Block Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Block Testers play a vital role in the production process by ensuring the quality and performance of engine blocks for various vehicles, from automobiles to heavy machinery.

1. Conducting Pressure and Leak Tests

One of their primary duties involves conducting pressure and leak tests on engine blocks to identify any potential defects or weaknesses. This involves applying pressurized air or water to the blocks and monitoring for leaks or pressure drops.

- Operating pressure testing equipment

- Monitoring test results and identifying potential defects

2. Inspection and Analysis

Block Testers also inspect engine blocks for physical defects, such as cracks, deformations, or machining errors. They use precision measuring tools, gauges, and visual inspection techniques to detect any irregularities that could affect the block’s performance.

- Examining blocks for surface defects, dimensional accuracy, and alignment

- Utilizing measurement instruments to verify specifications

3. Recording and Reporting

Accurately documenting test results and observations is essential for Block Testers. They maintain detailed records of all inspections and tests, ensuring that any identified defects are communicated to appropriate personnel for further evaluation and corrective action.

- Logging test data and observations

- Reporting defects and irregularities to supervisors

4. Maintaining Equipment

Regular maintenance and calibration of testing equipment are crucial for ensuring the accuracy and reliability of test results. Block Testers are responsible for performing routine maintenance tasks and calibrating equipment as per established protocols.

- Performing preventive maintenance on pressure testing equipment

- Ensuring equipment is properly calibrated

Interview Tips

Preparing effectively for a Block Tester interview can significantly enhance your chances of success. Here are some practical tips to help you ace the interview:

1. Research the Company and Role

Take the time to thoroughly research the company and the specific Block Tester role you are applying for. Familiarize yourself with their products, industry reputation, and the responsibilities of the position. This knowledge will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company website and read about their history, mission, and products.

- Review the job description and identify key skills and qualifications required.

2. Practice your Answers

Prepare thoughtful answers to common interview questions related to your technical skills, experience, and problem-solving abilities. Practice articulating your responses clearly and concisely, highlighting your relevant qualifications and how they align with the job requirements.

- Anticipate questions about your experience with pressure testing, leak detection, and engine block inspection.

- Prepare examples of how you have solved problems or detected defects in previous roles.

3. Showcase your Attention to Detail

Block Testers must possess a keen eye for detail and the ability to identify even minor defects. Emphasize your meticulous approach to inspections and your commitment to quality assurance. Highlight instances where your attention to detail led to successful defect detection or problem resolution.

- Describe specific techniques you use to ensure accuracy in your inspections.

- Share examples of how you have identified and reported defects that others may have missed.

4. Highlight your Communication and Teamwork Skills

Effective communication and teamwork are crucial in the role of a Block Tester. Demonstrate your ability to communicate clearly and effectively with colleagues, supervisors, and customers. Share examples of how you have worked collaboratively in team environments to achieve shared goals.

- Emphasize your ability to convey technical information to non-technical audiences.

- Provide instances of how you have successfully collaborated with others to solve problems or improve processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Block Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!