Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Blocker and Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

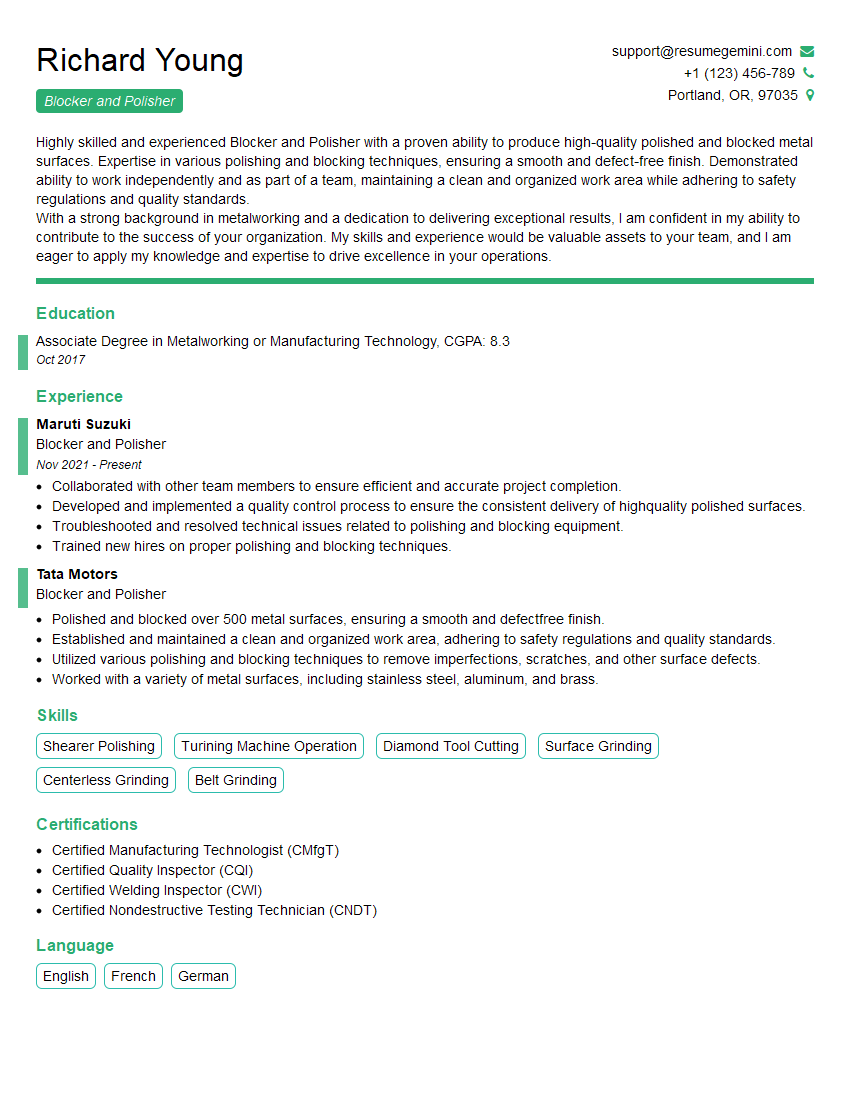

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blocker and Polisher

1. What is the role of a blocker and polisher in a jewelry manufacturing industry?

The role of a blocker and polisher in a jewelry manufacturing industry involves various tasks related to shaping and refining jewelry pieces. The responsibilities typically include:

- Blocking: Using hammers and mallets to shape and contour metal pieces into desired forms.

- Polishing: Using abrasive materials and polishing wheels to remove imperfections and achieve a smooth, reflective surface on jewelry.

- Sanding: Smoothing rough edges and removing excess metal using sandpaper or other abrasive materials.

- Filing: Using files to refine shapes and create intricate details on jewelry pieces.

- Soldering: Joining metal pieces together using solder and a torch.

2. Describe the different types of polishing wheels and their uses.

Types of Polishing Wheels:

- Sisal Wheels: Made from natural fibers, used for initial polishing and removing scratches.

- Cotton Wheels: Used with Tripoli or rouge compounds for fine polishing and achieving a high shine.

- Buffing Wheels: Made from soft materials like muslin or flannel, used for final polishing and creating a mirror-like finish.

- Emery Wheels: Used with abrasive compounds to remove heavy scratches or reshape jewelry pieces.

- Felt Wheels: Made from compressed wool or felt, used for polishing intricate areas or achieving a matte finish.

Uses of Polishing Wheels:

- Sisal wheels: Initial polishing, removing scratches, smoothing surfaces.

- Cotton wheels: Refining surfaces, achieving high shine.

- Buffing wheels: Creating smooth, mirror-like finishes.

- Emery wheels: Removing deep scratches, reshaping jewelry.

- Felt wheels: Polishing delicate areas, achieving matte finishes.

3. How do you determine the appropriate abrasive compound for a specific polishing task?

Determining the appropriate abrasive compound depends on the following factors:

- Material: Different metals require specific compounds, e.g., Tripoli for silver and gold, diamond paste for gemstones.

- Desired Finish: Coarse compounds (e.g., emery) remove scratches, while fine compounds (e.g., rouge) achieve high shine.

- Polishing Wheel: Different wheels require compatible compounds, e.g., Tripoli for sisal wheels, rouge for cotton wheels.

- Experience and Skill: Understanding the characteristics of compounds and wheels is essential for optimal results.

4. Describe the importance of adjusting the speed of the polishing wheel during the process.

Adjusting the speed of the polishing wheel is crucial for achieving the desired finish and preventing damage to the jewelry:

- Lower Speeds: Used for initial polishing, removing scratches, and achieving a smooth surface.

- Higher Speeds: Used for finer polishing, achieving a high shine, and removing minor imperfections.

- Too High Speeds: Can cause overheating, burning, or warping of the metal, especially with delicate pieces.

- Too Low Speeds: Inefficient and may not remove imperfections or achieve the desired finish.

5. How do you handle and care for delicate jewelry during the polishing process?

Handling delicate jewelry during polishing requires special care to avoid damage:

- Proper Support: Use soft cloths, sponges, or specialized holders to support the piece securely.

- Gentle Pressure: Apply minimal pressure while polishing, especially with prongs or delicate gemstones.

- Non-Abrasive Compounds: Use fine compounds and soft polishing wheels to prevent scratching.

- Controlled Speed: Use lower polishing speeds and avoid excessive friction.

- Frequent Inspections: Regularly check the piece for any signs of damage or wear.

6. Explain the different techniques used for soldering in jewelry making.

- Hard Soldering: Uses high-temperature solder and a torch to create strong, durable joints.

- Soft Soldering: Uses lower-temperature solder and a soldering iron for less permanent joints.

- Laser Soldering: Employs a focused laser beam to melt and join metal pieces.

- Ultrasonic Soldering: Uses ultrasonic vibrations to create friction and heat for joining metals.

7. Describe the safety precautions that should be taken when working with polishing equipment.

- Personal Protective Equipment (PPE): Wear safety glasses, gloves, and a mask to protect against dust and debris.

- Ventilation: Ensure adequate ventilation to remove dust and fumes.

- Guarding: Use machine guards to prevent accidental contact with moving parts.

- Electrical Safety: Ground equipment properly and inspect wires regularly.

- Fire Safety: Keep a fire extinguisher nearby and avoid using flammable materials.

8. How do you troubleshoot common problems encountered during polishing?

- Scratches: Use a finer abrasive compound or polishing wheel.

- Uneven Finish: Adjust polishing wheel speed or use different compounds for different areas.

- Overheating: Reduce polishing speed or use water or coolant to reduce friction.

- Burn Marks: Stop polishing immediately and remove any burnt residue.

- Damaged Jewelry: Assess the damage and consider seeking professional repair services.

9. What methods do you use to measure and ensure the accuracy of jewelry dimensions?

- Calipers: Used to measure external and internal dimensions.

- Micrometer: Provides precise measurements of small dimensions.

- Ring Sizers: Specifically designed to measure ring sizes accurately.

- Gauges: Used to check the thickness of metal sheets.

- Digital Measuring Tools: Provide high-precision measurements using electronic sensors.

10. How do you stay updated with the latest techniques and advancements in the jewelry industry?

- Industry Events and Exhibitions: Attend trade shows and conferences to learn about new products and techniques.

- Professional Journals and Publications: Read industry-specific magazines and books to stay informed.

- Online Resources: Utilize websites, forums, and social media groups dedicated to jewelry making.

- Mentorship and Training: Seek guidance from experienced jewelers and participate in workshops.

- Continuing Education: Enroll in courses or workshops to enhance skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blocker and Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blocker and Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blockers and polishers play a crucial role in the manufacturing process by removing surface imperfections and polishing components to achieve a desired finish. Their meticulous work ensures that products meet quality standards and specifications.

1. Blocking

Blockers use abrasives and hand tools to remove excess material from castings or forgings, smoothing out rough surfaces and preparing them for further processing.

- Selecting and using appropriate abrasives and tools for different materials and finishes

- Manually removing excess material from castings or forgings

2. Polishing

Polishers employ specialized equipment, abrasives, and polishing compounds to create a smooth, lustrous finish on metal, plastic, or composite surfaces.

- Operating polishing machines to remove scratches, burrs, and surface imperfections

- Selecting and applying appropriate abrasives and compounds to achieve desired surface finish

3. Deburring

In addition to blocking and polishing, blockers and polishers may also be responsible for deburring, which involves removing sharp or rough edges from components to prevent injury or interference with assembly.

- Using hand tools or specialized equipment to remove burrs

- Ensuring that deburred components meet specified dimensional tolerances

4. Inspection and Quality Control

Blockers and polishers must adhere to strict quality standards and ensure that finished products meet specifications and customer requirements.

- Inspecting blocked and polished components for defects or inconsistencies

- Reporting any issues or non-conformances to supervisors

Interview Tips

1. Research the Company and Position

Before the interview, thoroughly research the company’s background, values, and the specific responsibilities of the Blocker and Polisher position. This will help you understand the company’s culture, expectations, and how your skills and experience align with the role.

2. Practice Answering Common Interview Questions

Anticipate common interview questions and prepare concise and thoughtful answers that highlight your relevant skills and experience. Practice answering questions related to your ability to operate polishing equipment, your attention to detail, and your commitment to quality.

- Example: “Describe your experience in using polishing equipment and achieving different surface finishes.”

3. Emphasize Attention to Detail and Quality

Blockers and polishers play a vital role in ensuring product quality, so it’s crucial to convey your keen eye for detail and commitment to producing high-quality work. Provide examples of your ability to identify and correct surface imperfections and your willingness to go the extra mile to meet standards.

- Example: “In my previous role, I was responsible for polishing medical implants. I took pride in ensuring that every implant met the exacting specifications and surface finish required for optimal performance.”

4. Explain Your Ability to Work Independently and as Part of a Team

Blockers and polishers often work independently but may also need to collaborate with other team members. Demonstrate your ability to work autonomously and manage your time effectively. Also, highlight your teamwork skills and your willingness to contribute to a positive work environment.

- Example: “While I’m comfortable working independently, I also enjoy collaborating with others to troubleshoot issues and optimize processes.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blocker and Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!