Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bloom Conveyor Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bloom Conveyor Operator so you can tailor your answers to impress potential employers.

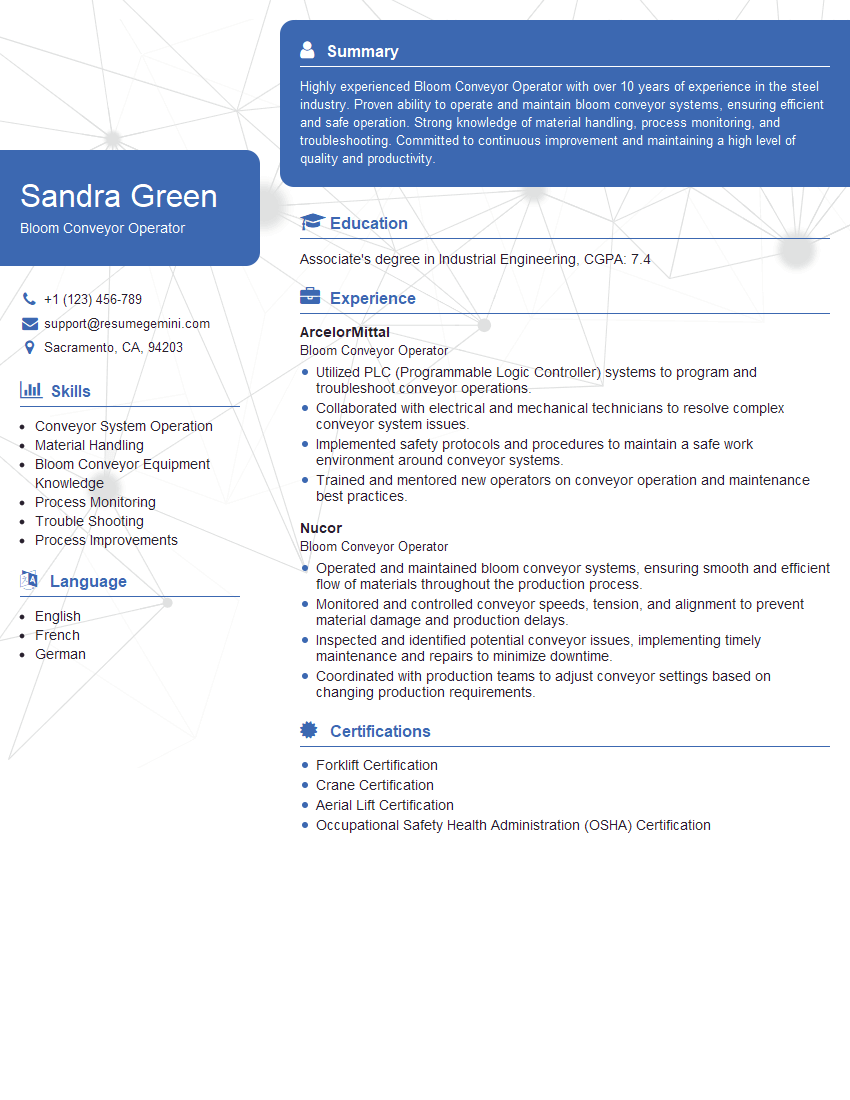

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bloom Conveyor Operator

1. Explain the role of a Bloom Conveyor Operator in detail?

- Monitor and control the operation of bloom conveyors, ensuring efficient material handling

- Identify and address conveyor malfunctions promptly to prevent production disruptions

- Maintain a safe and clean work environment, adhering to established safety protocols

- Communicate effectively with team members, supervisors, and external stakeholders

- Follow established procedures and regulations, ensuring compliance and operational efficiency

2. Describe the key maintenance procedures you are familiar with for bloom conveyors?

Preventive Maintenance

- Regular inspections to identify potential issues

- Lubrication and greasing of moving parts

- Belt tension checks and adjustments

- Cleaning and debris removal

Corrective Maintenance

- Troubleshooting and repair of conveyor malfunctions

- Replacement of worn or damaged components

- Electrical and mechanical repairs as needed

3. What safety precautions are essential to observe when operating a bloom conveyor?

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection

- Maintain a safe distance from moving machinery

- Be aware of pinch points and other potential hazards

- Follow lockout/tagout procedures during maintenance activities

- Report any unsafe conditions or potential hazards immediately

4. How do you ensure the efficient operation of bloom conveyors, minimizing downtime?

- Regular preventive maintenance to identify and address potential issues early on

- Prompt troubleshooting and repair of any malfunctions to avoid production delays

- Effective communication with maintenance personnel and supervisors to coordinate repairs and minimize downtime

- Adhering to established maintenance schedules and procedures

- Monitoring conveyor performance and identifying areas for improvement

5. Describe the types of conveyors, their key features, and their applications in material handling?

Belt Conveyors

- Continuous belts transport materials over long distances

- Suitable for a wide range of materials, including bulk solids, packages, and more

Roller Conveyors

- Utilize rotating rollers to move materials

- Ideal for conveying lightweight to medium-weight items

Chain Conveyors

- Use chains to transport materials

- Suitable for heavy-duty applications and incline/decline conveying

6. What types of sensors are commonly used in bloom conveyor systems and what is their purpose?

Position Sensors

- Monitor the position of the conveyor belt, detecting deviations

Speed Sensors

- Measure the speed of the conveyor belt

Temperature Sensors

- Detect excessive temperatures in conveyor components, preventing overheating

Load Sensors

- Monitor the weight of materials on the conveyor belt

7. Explain the importance of proper belt tension in bloom conveyor systems.

- Prevents belt slippage, ensuring proper material movement

- Reduces wear and tear on the belt and conveyor components

- Improves conveyor efficiency and longevity

8. Discuss the role of alignment in conveyor systems and how misalignment can affect performance.

- Proper alignment ensures smooth material flow and prevents belt damage

- Misalignment can cause excessive friction, wear, and reduced conveyor efficiency

9. Describe the safety protocols you have developed and implemented to prevent accidents in the bloom conveyor area?

- Established clear operating procedures and training for operators

- Regular inspections and maintenance of conveyors and related equipment

- Enforced the use of appropriate PPE and lockout/tagout procedures

- Implementation of emergency response plans and training for employees

10. Share an example of a successful improvement you implemented in a bloom conveyor system, resulting in enhanced performance or cost savings.

- Identified and replaced inefficient conveyor components, leading to reduced energy consumption

- Optimized belt tension to improve material flow and increase conveyor life

- Implemented a preventive maintenance program, minimizing unplanned downtime

11. Explain the importance of record-keeping and documentation in maintaining bloom conveyor systems.

- Records provide a history of maintenance activities and repairs

- Documentation aids in troubleshooting and identifying trends

- Helps ensure compliance with safety regulations

- Facilitates communication and knowledge sharing among team members

12. Discuss the challenges and opportunities you foresee in the field of bloom conveyor operations in the coming years.

- Increased automation and integration with other systems

- Adoption of data analytics for predictive maintenance and optimization

- Emergence of new materials and conveyor technologies

- Opportunities for career advancement and specialization

13. Describe your experience in working with a team to achieve common goals in a bloom conveyor operation environment

- Collaborated with team members to troubleshoot and resolve conveyor malfunctions efficiently

- Participated in regular meetings to discuss improvements and best practices

- Assisted colleagues with training and knowledge sharing to enhance overall team performance

14. Share a situation where you had to make a quick decision under pressure while operating a bloom conveyor system

- Detected a potential belt misalignment that could have caused a major breakdown

- Promptly adjusted the tension and realigned the belt, preventing downtime

- Communicated the situation to supervisors and ensured appropriate follow-up maintenance

15. Explain your understanding of the environmental impact of bloom conveyor operations and how you contribute to sustainability

- Adhere to energy-efficient practices to minimize power consumption

- Properly dispose of lubricants and other waste products

- Participate in recycling programs to reduce waste

- Educate colleagues on environmentally friendly practices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bloom Conveyor Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bloom Conveyor Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bloom Conveyor Operators are responsible for managing bloom conveyors in a steel mill.

1. Operating Bloom Conveyor

The key responsibility is to operate the bloom conveyor system, ensuring efficient transportation of blooms from the caster to the next processing step.

2. Monitoring Equipment

Operators are also responsible for monitoring the conveyor system, checking for any malfunctions or potential issues, and taking corrective actions to maintain smooth operation.

3. Troubleshooting and Maintenance

Troubleshooting is a critical aspect of their role, as they need to identify and resolve any issues quickly to minimize downtime.

4. Following Safety Procedures

Adhering to safety protocols is paramount, as their tasks involve working with heavy machinery in a potentially hazardous environment.

Interview Tips

Preparing well for an interview is crucial. Here are some tips to help you ace the interview for a Bloom Conveyor Operator position:

1. Research the Company and Role

Be prepared to discuss your understanding of the steel industry, the company’s operations, and the specific role you are applying for.

2. Highlight Relevant Experience

Emphasize your experience in operating and maintaining conveyor systems, troubleshooting equipment, and adhering to safety protocols.

3. Practice STAR Method

Use the STAR method to answer behavioral questions. Provide specific examples and quantify your achievements where possible.

4. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer, demonstrating your interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bloom Conveyor Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!