Are you gearing up for an interview for a Blooming Mill Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Blooming Mill Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

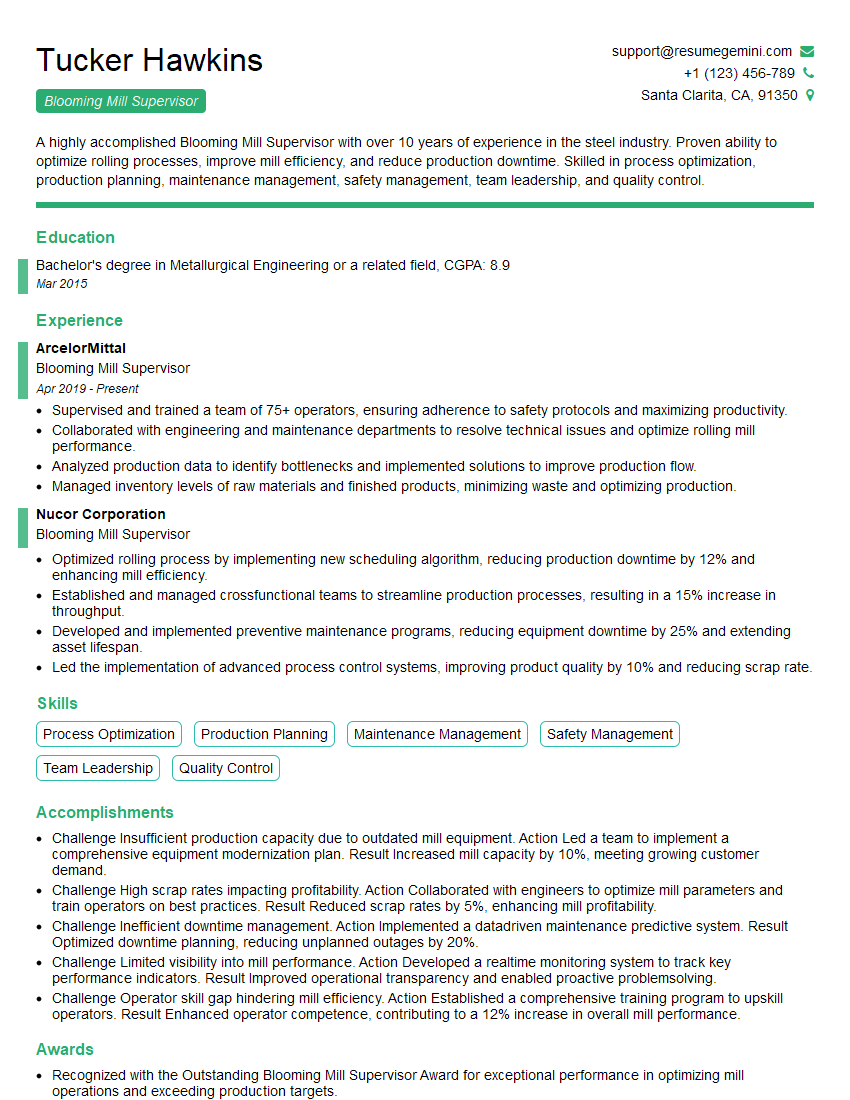

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blooming Mill Supervisor

1. Explain the process of setting up a blooming mill?

The setup process of a blooming mill involves several key steps:

- Roll Adjustment: The mill rolls are precisely adjusted to achieve the desired bloom dimensions and shape.

- Guide Alignment: Guides along the mill train are aligned to ensure proper positioning and control of the bloom.

- Temperature Control: Heating zones are calibrated to maintain the optimal temperature for rolling, ensuring proper deformation and material properties.

- Speed Optimization: Rolling speeds are carefully calculated and set to maximize production efficiency while maintaining product quality.

- Lubrication System: The lubrication system is inspected and adjusted to provide optimal lubrication for the rolls and other moving parts.

2. How do you monitor and control the rolling process?

Monitoring Techniques:

- Temperature Sensors: Monitor the temperature of the bloom at various stages to ensure proper heating and avoid overheating.

- Roll Force and Torque Sensors: Measure the force and torque applied by the rolls, providing insights into the rolling process and bloom deformation.

- Visual Inspection: Regular visual checks of the bloom surface and mill components for any abnormalities or defects.

Control Mechanisms:

- Roll Gap Adjustment: Adjust the distance between the rolls to control the thickness and shape of the bloom.

- Roll Speed Control: Regulate the speed of the rolls to achieve the desired rolling rate and bloom quality.

- Temperature Regulation: Adjust the heating zones to maintain the optimal temperature for rolling.

3. What are the common defects that can occur in blooming mill operations, and how do you address them?

- Edge Cracks: Caused by excessive roll pressure or improper lubrication, leading to cracks along the edges of the bloom. Mitigation measures include adjusting roll pressure and optimizing lubrication.

- Centerline Segregation: Occurs when the bloom’s center is not properly mixed, resulting in a weak core. Proper homogenization techniques during casting can prevent this defect.

- Surface Scabs: Formed by impurities or scale on the bloom’s surface, creating imperfections. Regular descaling and ensuring clean rolling surfaces can minimize scabs.

- Roll Wear: Gradual wear of the rolls can affect product quality. Regular maintenance and roll replacement are essential to prevent excessive wear.

4. Describe the safety protocols and emergency procedures in place for blooming mill operations.

Safety protocols and emergency procedures in a blooming mill include:

- Lockout/Tagout Procedures: Ensure proper isolation and de-energization of equipment before maintenance or repairs.

- Emergency Stop Buttons: Located throughout the mill to immediately halt operations in case of emergencies.

- Regular Safety Inspections: Regular checks of equipment, electrical systems, and work areas to identify and address potential hazards.

- Training and Certification: Comprehensive training and certification programs for operators to ensure proper knowledge and adherence to safety protocols.

- Emergency Response Teams: Dedicated teams trained to respond to emergencies and coordinate evacuation and medical assistance.

5. How do you optimize production efficiency in a blooming mill?

- Minimize Setup Time: Streamline setup procedures to reduce downtime between different bloom specifications.

- Optimize Rolling Parameters: Fine-tune roll gap, roll speed, and temperature settings to achieve maximum rolling efficiency and bloom quality.

- Preventive Maintenance: Regular equipment inspections and maintenance to prevent breakdowns and ensure smooth operations.

- Operator Training: Train operators on best practices and efficient operating techniques.

- Data Analysis: Collect and analyze data on production rates, defects, and equipment performance to identify areas for improvement.

6. How do you manage a team of operators in a blooming mill?

Team management in a blooming mill involves:

- Communication and Coordination: Clear communication and effective coordination among operators to ensure smooth operation and timely response to changes.

- Training and Development: Provide training opportunities to enhance operators’ skills and knowledge.

- Delegate Responsibilities: Assign tasks and responsibilities based on individual competencies to optimize team performance.

- Performance Monitoring: Regularly evaluate operator performance to identify areas for improvement and recognize achievements.

- Team Building: Foster a positive and collaborative team environment to enhance productivity and motivation.

7. Explain the principles of material flow and temperature control in a blooming mill.

Material flow in a blooming mill is managed to ensure:

- Consistent Feeding: Ingots or slabs are fed into the mill at a controlled rate to maintain a steady flow.

- Roll Gap Optimization: Roll gaps are adjusted to accommodate the thickness of the material and achieve the desired bloom dimensions.

- Temperature Control: Heating zones are utilized to raise the material to the optimal rolling temperature and maintain it throughout the process.

8. How do you calibrate and maintain the accuracy of the blooming mill’s equipment?

- Roll Alignment: Use precision instruments to align the rolls to ensure accurate rolling and prevent bloom defects.

- Sensor Calibration: Calibrate temperature sensors, roll force sensors, and other instrumentation regularly to ensure reliable data for process control.

- Regular Inspections: Conduct thorough inspections of all equipment, including rolls, bearings, guides, and hydraulic systems, to identify and address potential issues.

9. Discuss the role of automation in modern blooming mill operations.

Automation in blooming mills has revolutionized operations, bringing several benefits:

- Increased Productivity: Automated systems enable faster and more efficient rolling processes, maximizing production output.

- Improved Accuracy: Automation reduces human error, resulting in more consistent and precise rolling results.

- Enhanced Safety: Automated systems handle hazardous tasks, such as bloom manipulation, minimizing risks for operators.

- Data Collection and Analysis: Automated systems collect operational data, allowing for in-depth analysis and optimization of the rolling process.

10. Describe your experience with process improvement initiatives in blooming mill operations.

I have actively participated in several process improvement initiatives in my previous role as Blooming Mill Supervisor:

- Roll Profile Optimization: Conducted a study to identify the optimal roll profile for different bloom sizes, resulting in reduced rolling force and improved bloom quality.

- Automation Implementation: Led the implementation of an automated bloom handling system, significantly increasing productivity and enhancing safety.

- Preventive Maintenance Optimization: Developed a comprehensive preventive maintenance plan, reducing unplanned downtime and extending equipment lifespan.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blooming Mill Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blooming Mill Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Production Supervision

Oversee all aspects of the blooming mill production process, including scheduling, coordination, and monitoring.

- Establish and implement production targets, ensuring efficient use of resources.

- Monitor production data to identify bottlenecks and implement corrective actions.

2. Quality Control

Ensure the quality of steel products produced by the blooming mill meets specifications.

- Conduct regular quality checks and audits on raw materials and finished products.

- Implement quality control measures to minimize defects and maintain high standards.

3. Equipment Maintenance

Supervise the maintenance and repair of blooming mill equipment to ensure optimal performance.

- Coordinate with maintenance teams to plan and schedule maintenance activities.

- Oversee equipment repairs to ensure safety and efficiency.

4. Safety and Environmental Compliance

Maintain a safe and environmentally compliant workplace in accordance with industry regulations.

- Enforce safety protocols and provide training to employees.

- Monitor environmental compliance and implement measures to reduce emissions.

5. Team Management

Lead and motivate a team of operators and maintenance personnel.

- Provide clear instructions and guidance to team members.

- Resolve conflicts and issues within the team effectively.

Interview Tips

1. Research the Company and the Role

Familiarize yourself with the steel industry, the company’s operations, and the specific requirements of the Blooming Mill Supervisor role.

2. Highlight Relevant Skills and Experience

Emphasize your technical knowledge of the blooming mill process, as well as your leadership, quality control, and safety experience.

3. Prepare Examples of Successes

Quantify your accomplishments and be prepared to provide specific examples of how you have improved production, reduced defects, or enhanced safety in previous roles.

4. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to identify and resolve challenges. Prepare examples of how you have overcome obstacles or made improvements in previous work settings.

5. Ask Thoughtful Questions

Ask insightful questions about the role, the company, and the industry to demonstrate your engagement and curiosity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blooming Mill Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!