Are you gearing up for a career in Blow Molding Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Blow Molding Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

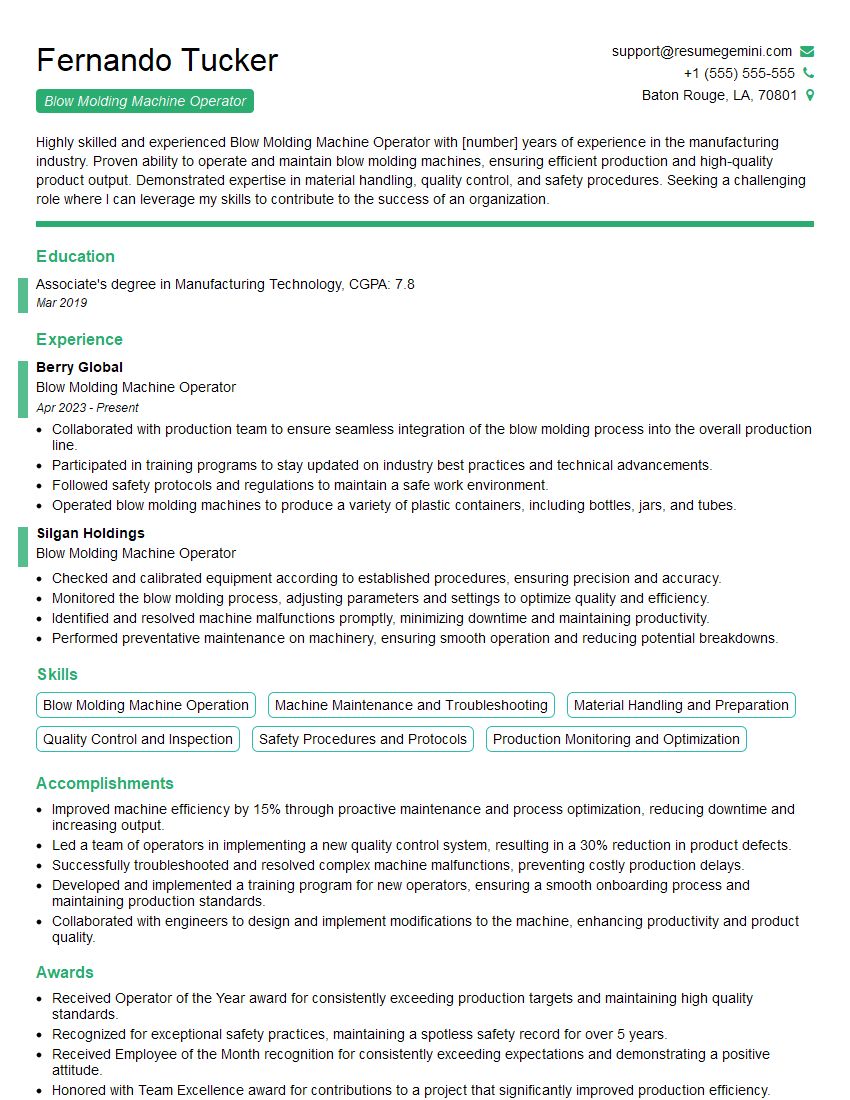

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blow Molding Machine Operator

1. How do you ensure the proper thickness of the blown product?

- Adjust the parison dimensions by controlling the injection volume and velocity.

- Monitor the parison stretch ratio using video sensors or laser gauges.

- Fine-tune the blow molding parameters such as blow pressure, cooling time, and mold temperature.

2. Describe the typical maintenance procedures for a blow molding machine.

Preventive Maintenance

- Lubrication of moving parts

- Inspection and cleaning of molds and dies

- Monitoring and adjustment of hydraulic and pneumatic systems

Corrective Maintenance

- Troubleshooting and repair of electrical faults

- Replacement of worn or damaged parts

- Overhaul of major components

3. How do you handle defects in blown plastic products?

- Identify the type and cause of the defect (e.g., wrinkles, gels, pinholes)

- Determine the corrective action based on the defect (e.g., adjusting blow molding parameters, inspecting molds)

- Implement quality control measures to prevent future occurrences

4. Explain the importance of parison quality in blow molding.

- Uniform thickness distribution in the final product

- Minimized wrinkling or sagging during blowing

- Reduced cycle time due to optimized parison size and shape

5. How do you optimize the energy efficiency of a blow molding machine?

- Use energy-efficient injection and blow units

- Optimize cycle times to minimize energy consumption

- Install heat recovery systems to utilize waste heat

- Implement preventive maintenance to reduce energy losses due to friction and wear

6. Describe the different types of materials used in blow molding.

- Polyethylene (PE): High-density, low-density, linear low-density

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyethylene terephthalate (PET)

- Polycarbonate (PC)

7. What are the advantages of using infrared sensors in blow molding machines?

- Real-time monitoring of parison temperature and thickness

- Early detection of potential defects

- Improved product consistency and quality

8. How do you ensure the safety of operators working with blow molding machines?

- Provide proper training on machine operation and safety protocols

- Implement machine guarding and safety interlocks

- Regularly inspect and maintain safety components

- Enforce the use of personal protective equipment (PPE)

9. Discuss the factors that affect the mold design for blow molding.

- Product geometry and dimensions

- Production rate and cycle time

- Material properties and shrinkage

- Cooling system design

- Ejection system requirements

10. What are the recent advancements in blow molding technology?

- Multi-layer blow molding for improved product properties

- Use of biodegradable and sustainable materials

- Integration of automation and robotics

- Advanced process control systems for increased efficiency

- Virtual and augmented reality for operator training and maintenance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blow Molding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blow Molding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Blow Molding Machine Operators are responsible for operating and maintaining blow molding machines, used to create plastic products by injecting molten plastic into a mold.

1. Machine Operation

Operate blow molding machines, including setting up, calibrating, and adjusting equipment.

- Monitor machine performance and make adjustments to ensure optimal production.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

2. Mold Management

Install, remove, and maintain molds according to production schedules.

- Inspect molds for damage and wear, and perform necessary repairs.

- Optimize mold settings to achieve desired product quality and efficiency.

3. Material Handling

Load and unload plastic resins into machines.

- Monitor material levels and ensure proper flow through the molding process.

- Maintain a clean work area to prevent contamination of products.

4. Quality Control

Perform quality checks on finished products to ensure they meet specifications.

- Inspect products for defects, such as cracks, scratches, or discoloration.

- Maintain records of quality checks and report any issues to supervisors.

Interview Preparation Tips

To prepare for an interview as a Blow Molding Machine Operator, consider the following tips:

1. Research the Industry

Learn about the blow molding industry, including the different types of machines, resins, and products produced.

- Visit industry websites and trade publications.

- Network with professionals in the field to gain insights and make connections.

2. Practice Machine Operation

If possible, practice operating a blow molding machine to demonstrate your skills and knowledge.

- Attend training workshops or courses offered by equipment manufacturers.

- Volunteer or intern at a company that uses blow molding machines.

3. Highlight Your Troubleshooting Ability

Emphasize your ability to troubleshoot and resolve machine malfunctions quickly and efficiently.

- Provide specific examples of troubleshooting situations you have encountered and the steps you took to resolve them.

- Research common blow molding machine issues and prepare potential solutions.

4. Showcase Your Attention to Detail

Blow Molding Machine Operators must have a high level of attention to detail to ensure product quality.

- Describe your experience in inspecting products for defects and maintaining a clean work area.

- Explain how you ensure proper material handling and mold maintenance to prevent contamination.

5. Be Prepared for Physical Demands

Blow Molding Machine Operators may be required to lift heavy objects and work in a standing position for extended periods.

- Be ready to discuss your physical fitness and ability to perform the necessary tasks.

- If you have any physical limitations, be transparent with the interviewer and discuss potential accommodations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Blow Molding Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Blow Molding Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.