Feeling lost in a sea of interview questions? Landed that dream interview for Blower and Compressor Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Blower and Compressor Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

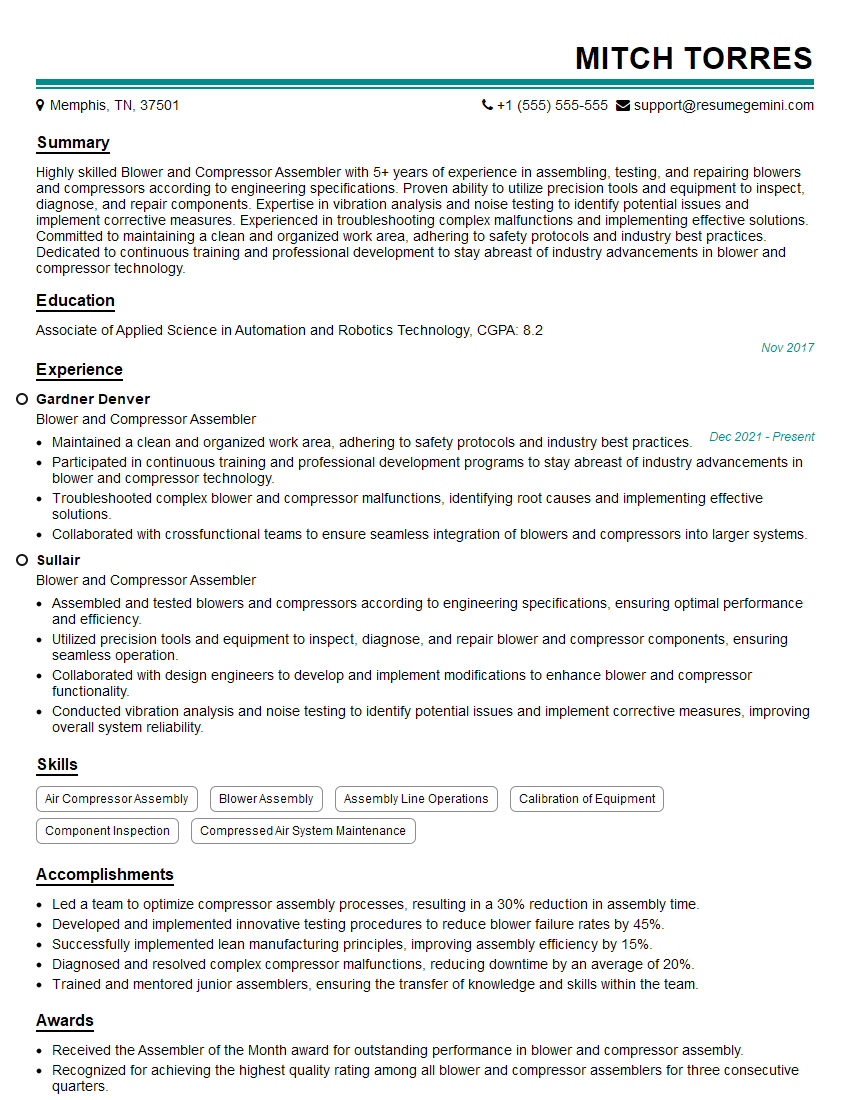

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Blower and Compressor Assembler

1. Describe the step-by-step process of assembling a blower?

- Inspect all components to ensure accuracy and quality.

- Mount the blower housing on a stable surface.

- Install the impeller inside the housing and secure it with bolts.

- Connect the motor to the impeller using a belt or shaft.

- Mount the motor on the housing and connect the electrical wiring.

- Install the inlet and outlet ports on the housing.

- Test the blower for proper rotation, vibration, and noise levels.

2. What are the different types of blowers you have experience with, explain their applications and advantages?

Positive displacement blowers

- Applications: Vacuum cleaners, air compressors, medical equipment.

- Advantages: High-pressure output, low noise levels.

Centrifugal blowers

- Applications: Industrial ventilation, air conditioning systems.

- Advantages: High flow rates, low maintenance.

Axial blowers

- Applications: Cooling electronics, personal ventilation.

- Advantages: Small size, low cost.

3. What techniques do you use to troubleshoot and repair compressors?

- Inspect for leaks, loose connections, and damaged components.

- Test electrical circuits for continuity and proper voltage.

- Analyze oil pressure, temperature, and flow rates.

- Check for mechanical vibrations and abnormal noises.

- Refer to technical manuals and consult with experienced technicians.

4. Describe the importance of proper lubrication in compressors, what types of lubricants are used and how often should they be changed?

- Lubrication reduces friction, prevents wear, and extends compressor life.

- Common lubricants include mineral oil, synthetic oil, and grease.

- Lubrication intervals vary depending on compressor type and operating conditions, typically ranging from 500 to 2000 hours.

5. What safety precautions should be taken when working with blowers and compressors?

- Wear appropriate personal protective equipment (PPE).

- Ensure proper ventilation and grounding.

- Follow lockout/tagout procedures during maintenance and repairs.

- Do not exceed the maximum pressure limits.

- Inspect and maintain equipment regularly to prevent accidents.

6. Explain the principle of operation of a reciprocating compressor, including the functions of its major components.

- The crankshaft rotates, causing the piston to move up and down.

- The intake valve opens, allowing air to enter the cylinder.

- The intake valve closes, and the piston compresses the air.

- The discharge valve opens, allowing the compressed air to exit the cylinder.

7. What types of sensors are used in blowers and compressors, describe their functions and how you would troubleshoot them?

Pressure sensors

- Function: Monitor pressure levels.

- Troubleshooting: Check for leaks, loose connections, or damaged diaphragms.

Temperature sensors

- Function: Monitor temperature levels.

- Troubleshooting: Check for loose connections, damaged probes, or calibration issues.

Vibration sensors

- Function: Detect excessive vibrations.

- Troubleshooting: Inspect for loose components, misalignment, or bearing wear.

8. How do you ensure the quality of assembled blowers and compressors before they are shipped to customers?

- Inspect all components for defects.

- Assemble and test each unit to ensure performance meets specifications.

- Conduct quality control checks throughout the assembly process.

- Obtain customer feedback and make improvements as necessary.

9. Describe your experience with using computer-aided design (CAD) software in your work as a blower and compressor assembler.

- Used CAD software to design and modify blower and compressor components.

- Created 3D models to visualize and analyze designs.

- Generated detailed drawings for production purposes.

10. What is your understanding of preventive maintenance for blowers and compressors?

- Regular inspections, cleaning, and lubrication to prevent breakdowns.

- Monitoring sensors and data logs to detect potential issues early.

- Following manufacturers’ recommended maintenance schedules.

- Scheduling downtime for proactive repairs and upgrades.

11. Can you explain the process of balancing a blower or compressor impeller, and what tools are commonly used for this task?

- Mount the impeller on a balancing machine.

- Spin the impeller at different speeds and measure the resulting vibrations.

- Add or remove weight to the impeller until the vibrations are minimized.

- Common tools used: Balancing machines, vibration analyzers, laser alignment tools.

12. What are the different types of seals used in blowers and compressors, and how do you select the appropriate seal for a specific application?

Mechanical seals

- Used for rotating shafts.

- Prevent leakage by contact between two sealing surfaces.

Lip seals

- Used for reciprocating shafts.

- Prevent leakage by a rubber lip that contacts the shaft.

O-rings

- Used for static or low-movement applications.

- Prevent leakage by compression between two surfaces.

13. How do you ensure that the assembled blowers and compressors meet the required performance specifications?

- Follow established assembly procedures and quality control standards.

- Use calibrated testing equipment to measure performance parameters.

- Compare test results to specifications and make adjustments as needed.

- Document all testing and inspection results for traceability.

14. Describe the importance of proper storage and handling of blower and compressor components to prevent damage and ensure their longevity.

- Store components in a clean and dry environment.

- Protect delicate components from impact and vibration.

- Use appropriate packaging materials to prevent corrosion and contamination.

- Follow manufacturers’ storage guidelines for specific components.

15. How do you stay updated with the latest advancements and best practices in blower and compressor assembly?

- Attend industry conferences and workshops.

- Read technical journals and research papers.

- Consult with suppliers and manufacturers for product updates.

- Receive training from experienced colleagues and supervisors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Blower and Compressor Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Blower and Compressor Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Blower and Compressor Assembler is responsible for assembling, testing, and inspecting blowers and compressors. They may also be involved in repairing and maintaining these machines.

1. Assembly

Assemble blowers and compressors according to blueprints and specifications.

- Install and secure components, such as impellers, shafts, and bearings.

- Ensure that all parts are properly aligned and tightened.

2. Testing

Test assembled blowers and compressors to ensure that they meet performance specifications.

- Conduct flow tests to measure air or gas volume and pressure.

- Monitor temperature and vibration levels to identify potential problems.

3. Inspection

Inspect blowers and compressors for defects before they are shipped to customers.

- Visually inspect components for damage or wear.

- Check for leaks and ensure that all seals are properly installed.

4. Troubleshooting

Troubleshoot and repair blower and compressor problems.

- Identify and resolve mechanical or electrical issues.

- Replace worn or damaged components.

Interview Tips

To help candidates ace their interview for a Blower and Compressor Assembler position, here are some interview preparation tips and hacks:

1. Research the company and the position

Take the time to learn about the company’s history, mission, and values. Research the specific Blower and Compressor Assembler position to gain insights into the responsibilities and expectations.

- This will demonstrate your interest in the position and show the interviewer that you are prepared.

- Example: “I understand that ABC Company is a leading manufacturer of blowers and compressors. I am particularly interested in your commitment to sustainability and innovation, as reflected in your recent investment in eco-friendly technologies.”

2. Highlight your technical skills

In your resume and during the interview, emphasize your technical skills and experience in assembling, testing, and troubleshooting blowers and compressors. Quantify your accomplishments whenever possible.

- For example, instead of saying “I have experience assembling blowers,” say “I assembled over 500 blowers during my time at XYZ Company, ensuring they met all performance specifications.”

- Example: “I have a strong understanding of the principles of fluid dynamics and thermodynamics, which enables me to identify and resolve performance issues in blowers and compressors efficiently.”

3. Emphasize your attention to detail

Blowers and compressors are complex machines that require precise assembly and inspection. Highlight your attention to detail and your ability to follow instructions carefully.

- Provide examples of times when you have successfully identified and corrected errors in assembly or inspection.

- Example: “In my previous role, I implemented a quality control process that reduced the number of defective blowers shipped to customers by 20%.”

4. Practice your answers to common interview questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Some common interview questions for a Blower and Compressor Assembler position include:

- Tell me about your experience assembling and testing blowers and compressors.

- Describe a time when you had to troubleshoot a problem with a blower or compressor.

- What are your strengths and weaknesses as a Blower and Compressor Assembler?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Blower and Compressor Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.