Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Board Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

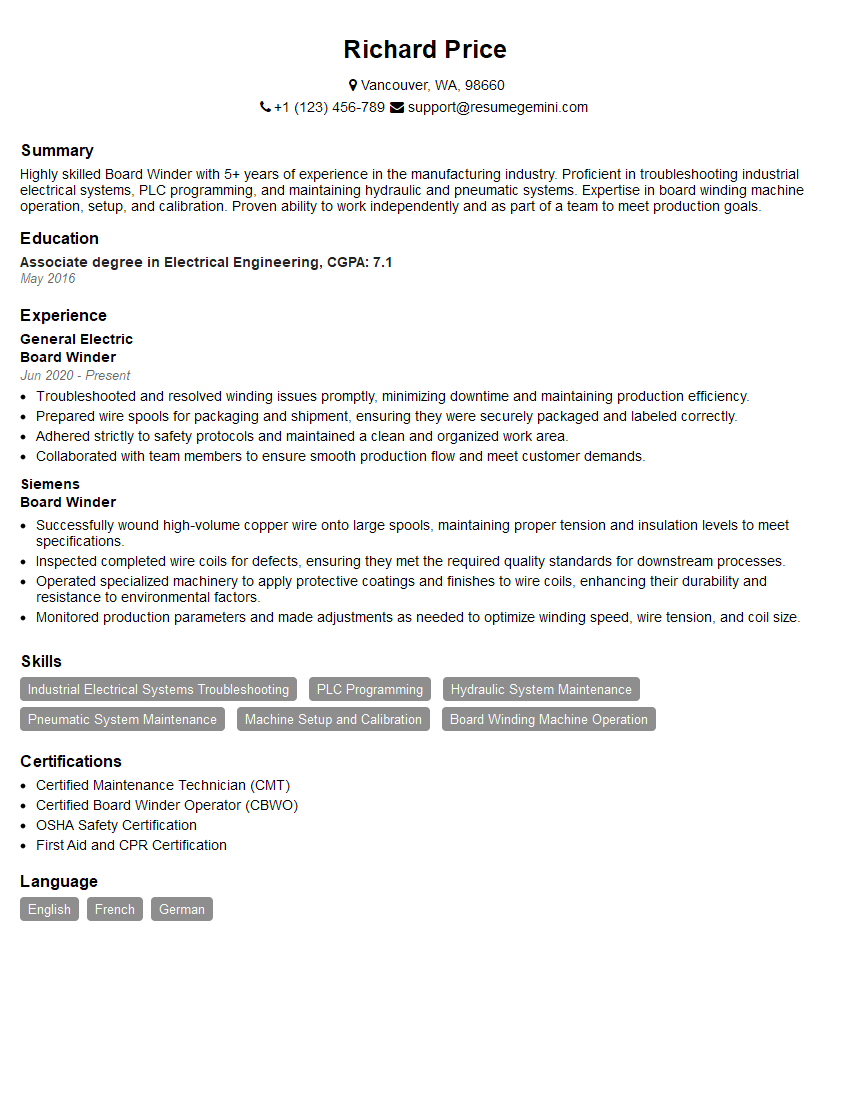

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Board Winder

1. What is the difference between a bobbin winder and a cone winder?

Sample Answer: – Bobbin winders are used to wind yarn onto bobbins, while cone winders are used to wind yarn onto cones. – Bobbins are cylindrical in shape, while cones are conical in shape. – Bobbins are typically used in sewing machines, while cones are typically used in weaving machines.

2. What are the different types of bobbin winders?

Sample Answer: – Manual bobbin winders are operated by hand. – Electric bobbin winders are powered by electricity. – Automatic bobbin winders are fully automated and can be programmed to wind bobbins to a specific size and shape.

3. What are the different types of cone winders?

Sample Answer: – Single-end cone winders wind one cone at a time. – Multi-end cone winders wind multiple cones at the same time. – Precision cone winders are used to wind cones to a very high degree of accuracy.

4. What are the factors that affect the quality of wound yarn?

Sample Answer: – The tension of the yarn – The speed of the winding machine – The type of yarn being wound – The condition of the winding machine

5. What are the common problems that can occur during winding?

Sample Answer: – Yarn breakage – Knots in the yarn – Uneven winding – Contamination of the yarn

6. How do you troubleshoot winding problems?

Sample Answer: – Check the tension of the yarn. – Check the speed of the winding machine. – Inspect the yarn for knots or other defects. – Clean the winding machine.

7. What are the safety precautions that must be taken when operating a bobbin winder or cone winder?

Sample Answer: – Wear gloves and eye protection. – Keep your hands away from moving parts. – Do not operate the machine if it is damaged. – Follow the manufacturer’s instructions for safe operation.

8. What is the role of a Board Winder in the textile industry?

Sample Answer: – Board winders are responsible for winding yarn onto bobbins or cones. – They must be able to operate a variety of winding machines and troubleshoot winding problems. – They must also be able to maintain a clean and safe work environment.

9. What are the skills and qualifications that are required to be a Board Winder?

Sample Answer: – Ability to operate a variety of winding machines – Knowledge of yarn tension, speed, and winding techniques – Troubleshooting skills – Maintenance skills – Adherence to safety regulations

10. What is your experience with winding machines?

Sample Answer: – I have operated a variety of winding machines, including manual, electric, and automatic bobbin winders and cone winders. – I have experience with winding a variety of yarns, including cotton, polyester, and nylon. – I am proficient in troubleshooting winding problems and maintaining winding machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Board Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Board Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Board Winders are responsible for operating winding machines that wrap materials such as paper, plastic, or metal foils onto reels or cores. They play a crucial role in ensuring the smooth production of various products, from packaging materials to electrical components.

1. Operating Winding Machines

Board Winders are skilled in operating a variety of winding machines, including single- and double-shaft winders, slitters, and rewinders. They must be proficient in setting up and adjusting these machines to meet specific winding requirements, such as tension, width, and speed.

- Loading and unloading reels or cores onto the winding machine

- Adjusting machine settings to ensure proper winding tension and alignment

2. Monitoring Production Process

Board Winders are responsible for monitoring the winding process to ensure the production of high-quality reels. They must be able to identify and resolve any issues that may arise during winding, such as breaks or misalignments.

- Monitoring reel diameter and tension to ensure consistent winding

- Inspecting reels for defects and taking corrective actions

3. Maintaining Equipment

Board Winders are responsible for maintaining the winding machines they operate. They must perform routine cleaning and lubrication, as well as minor repairs, to ensure optimal machine performance and prevent breakdowns.

- Cleaning and lubricating machine components

- Performing basic repairs, such as replacing worn parts

4. Material Handling

Board Winders handle a variety of materials, including paper, plastic, and metal foils. They must be able to safely and efficiently load and unload heavy reels and cores, as well as dispose of waste materials.

- Loading and unloading reels and cores using forklifts or other lifting equipment

- Disposing of waste materials according to established procedures

Interview Tips

Preparing for a Board Winder interview requires a combination of technical knowledge, understanding of the industry, and strong interpersonal skills. Here are some tips and hacks to help candidates ace the interview:

1. Research the Company and Position

Researching the company and the specific job position is essential. Candidates should visit the company’s website, read industry publications, and network with people in the field to gain insights into the company’s culture, products, and services. Understanding the specific requirements of the job will help candidates tailor their answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, mission, and products.

- Read industry publications to stay up-to-date on trends and best practices.

- Network with people in the field to gain insights into the company’s culture and specific job requirements.

2. Highlight Technical Skills and Experience

Board Winders should highlight their technical skills and experience in operating winding machines. They should be prepared to discuss their knowledge of different types of winding machines, as well as their experience in setting up, adjusting, and troubleshooting these machines.

- Quantify their experience by providing specific examples of their accomplishments.

- Use action verbs to describe their skills and responsibilities.

- Be prepared to discuss their experience in a variety of winding applications.

3. Emphasize Quality Control and Problem Solving

Board Winders should emphasize their commitment to quality control and problem solving. They should be able to demonstrate their ability to identify and resolve issues that may arise during the winding process. They should also be able to discuss their experience in maintaining and troubleshooting winding machines.

- Provide examples of how they have identified and resolved problems in the past.

- Discuss their experience in maintaining and troubleshooting winding machines.

- Explain their commitment to quality control and continuous improvement.

4. Communicate Effectively

Board Winders should be able to communicate effectively with supervisors, colleagues, and customers. They should be able to clearly explain technical information and provide updates on the progress of their work. They should also be able to work independently and as part of a team.

- Practice active listening skills.

- Be prepared to answer questions clearly and concisely.

- Be able to work independently and as part of a team.

5. Dress Professionally and Arrive on Time

First impressions matter. Candidates should dress professionally and arrive on time for their interview. They should also be polite and respectful to everyone they meet, including the receptionist, interviewers, and other employees.

- Dress in business attire.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

Next Step:

Now that you’re armed with the knowledge of Board Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Board Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini