Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bobbin Cleaning Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bobbin Cleaning Machine Operator so you can tailor your answers to impress potential employers.

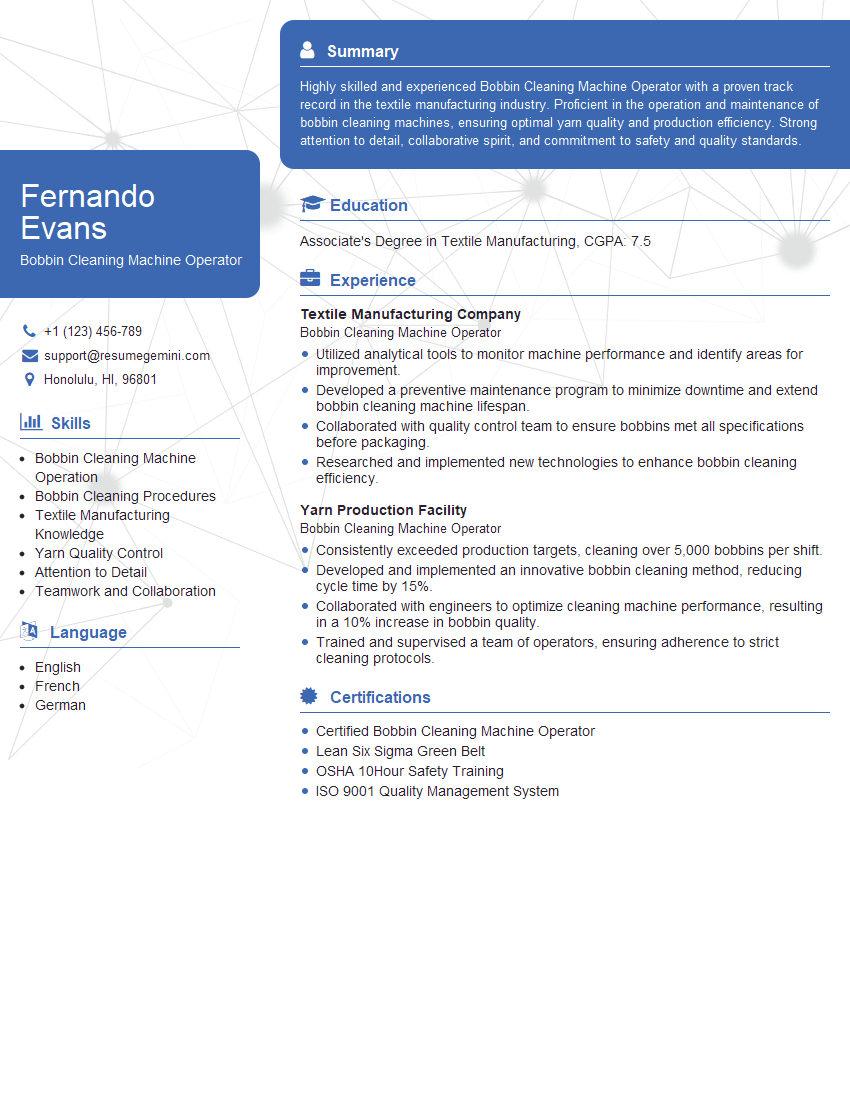

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bobbin Cleaning Machine Operator

1. What is the primary function of a bobbin cleaning machine?

The primary function of a bobbin cleaning machine is to remove contaminants, such as dirt, dust, and lint, from bobbins used in textile manufacturing processes. This process ensures that the bobbins are clean and free of debris, which can affect the quality of the yarn produced.

2. Describe the different types of bobbin cleaning machines.

Ultrasonic Cleaners

- Utilizes high-frequency sound waves to create cavitation bubbles that dislodge contaminants.

- Suitable for delicate bobbins and complex geometries.

Mechanical Cleaners

- Employs brushes or other mechanical devices to scrub and remove contaminants.

- Can handle larger batches and heavy-duty cleaning.

Air-Blast Cleaners

- Uses compressed air to blow away contaminants.

- Suitable for quick and efficient cleaning without water or chemicals.

3. What are the key operating parameters of a bobbin cleaning machine?

- Cleaning time: Determines the duration of the cleaning cycle.

- Cleaning solution: Type and concentration of cleaning agents used.

- Temperature: Optimal temperature for cleaning solution effectiveness.

- Pressure: Air pressure for air-blast cleaners or mechanical force for mechanical cleaners.

4. How do you ensure the quality of bobbins after cleaning?

- Visual inspection: Check for visible contaminants and cleanliness.

- Microscopic examination: Use a microscope to verify the removal of microscopic debris.

- Yarn quality testing: Test the quality of yarn produced using cleaned bobbins to ensure no contamination.

5. Describe your experience in troubleshooting bobbin cleaning machines.

- Diagnose common issues such as clogged filters, worn brushes, or air pressure problems.

- Perform necessary repairs or adjustments to restore the machine’s functionality.

- Document troubleshooting steps and implement preventive maintenance measures.

6. How do you maintain a safe working environment while operating a bobbin cleaning machine?

- Wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a mask.

- Follow safety protocols for handling cleaning solutions and solvents.

- Ensure proper ventilation to prevent exposure to harmful fumes.

7. What is your understanding of the environmental regulations related to bobbin cleaning operations?

- Awareness of waste disposal regulations for cleaning solutions and solvents.

- Knowledge of air emission standards and the use of exhaust systems.

- Compliance with environmental guidelines to minimize the impact on the environment.

8. How do you prioritize tasks and manage your time effectively when operating multiple bobbin cleaning machines?

- Establish a cleaning schedule based on production requirements.

- Prioritize cleaning based on bobbin type and contamination level.

- Monitor machine performance and adjust settings as needed to optimize cleaning efficiency.

9. Describe your experience in working as part of a team in a textile manufacturing environment.

- Effective communication and collaboration with colleagues.

- Understanding of production processes and quality standards.

- Ability to support other team members and contribute to overall production goals.

10. How do you stay updated with the latest advancements and best practices in bobbin cleaning technology?

- Attend industry conferences and workshops.

- Read technical articles and research papers.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bobbin Cleaning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bobbin Cleaning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bobbin Cleaning Machine Operator is responsible for the smooth operation of the bobbin cleaning machine. The primary responsibility is to ensure that bobbins are cleaned and maintained to the highest quality standards

1. Machine Operation

intro paragraph

- Operate and monitor the bobbin cleaning machine to ensure proper cleaning and maintenance of bobbins.

- Adjust machine settings, such as temperature, pressure, and speed, to optimize cleaning performance.

2. Quality Control

intro paragraph

- Inspect bobbins before and after cleaning to ensure they meet quality standards.

- Identify and address any defects or imperfections in bobbins.

3. Maintenance and Troubleshooting

intro paragraph

- Perform regular maintenance tasks on the bobbin cleaning machine, including cleaning, lubrication, and minor repairs.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

4. Safety and Compliance

intro paragraph

- Follow all safety protocols and procedures.

- Ensure that the work area is clean, organized, and free of hazards.

Interview Tips

Preparing for an interview for a Bobbin Cleaning Machine Operator position requires careful consideration of the key responsibilities of the role and the specific skills and experience that will be required to succeed. Here are a few tips to help you prepare and ace your interview:

1. Research the company and the position

Take the time to research the company you’re applying to, including its products, services, and culture. Familiarize yourself with the specific requirements of the Bobbin Cleaning Machine Operator position, paying attention to the key responsibilities outlined in the job description.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

2. Practice answering common interview questions

There are certain questions that are commonly asked in interviews for Bobbin Cleaning Machine Operator positions. Practice answering these questions in a clear and concise manner, highlighting your relevant skills and experience. Some common questions include:

- Tell me about your experience operating bobbin cleaning machines.

- How do you ensure that bobbins are cleaned to the highest quality standards?

- What troubleshooting steps would you take if the bobbin cleaning machine malfunctioned?

3. Be prepared to discuss your safety knowledge

Safety is a critical aspect of operating bobbin cleaning machines. Be prepared to discuss your knowledge of safety protocols and procedures, and how you would ensure a safe work environment.

- Explain your understanding of the potential hazards associated with operating bobbin cleaning machines.

- Describe your experience with using personal protective equipment (PPE).

4. Show your passion for the industry

Hiring managers are looking for candidates who are passionate about the industry and eager to learn and grow. Demonstrate your passion for the textile or manufacturing industry by discussing your interest in the field, your previous experience, and your goals for the future.

- Share examples of projects or initiatives that you have been involved in related to the textile or manufacturing industry.

- Express your interest in staying up-to-date on the latest trends and technologies in the field.

5. Prepare questions to ask the interviewer

Asking well-informed questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few thoughtful questions to ask the interviewer, such as:

- What are the biggest challenges facing the company in the textile industry?

- What opportunities are there for professional development and advancement within the company?

- What is the company’s culture like, and how do you think I would fit in?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bobbin Cleaning Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!