Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bobbin Marker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bobbin Marker so you can tailor your answers to impress potential employers.

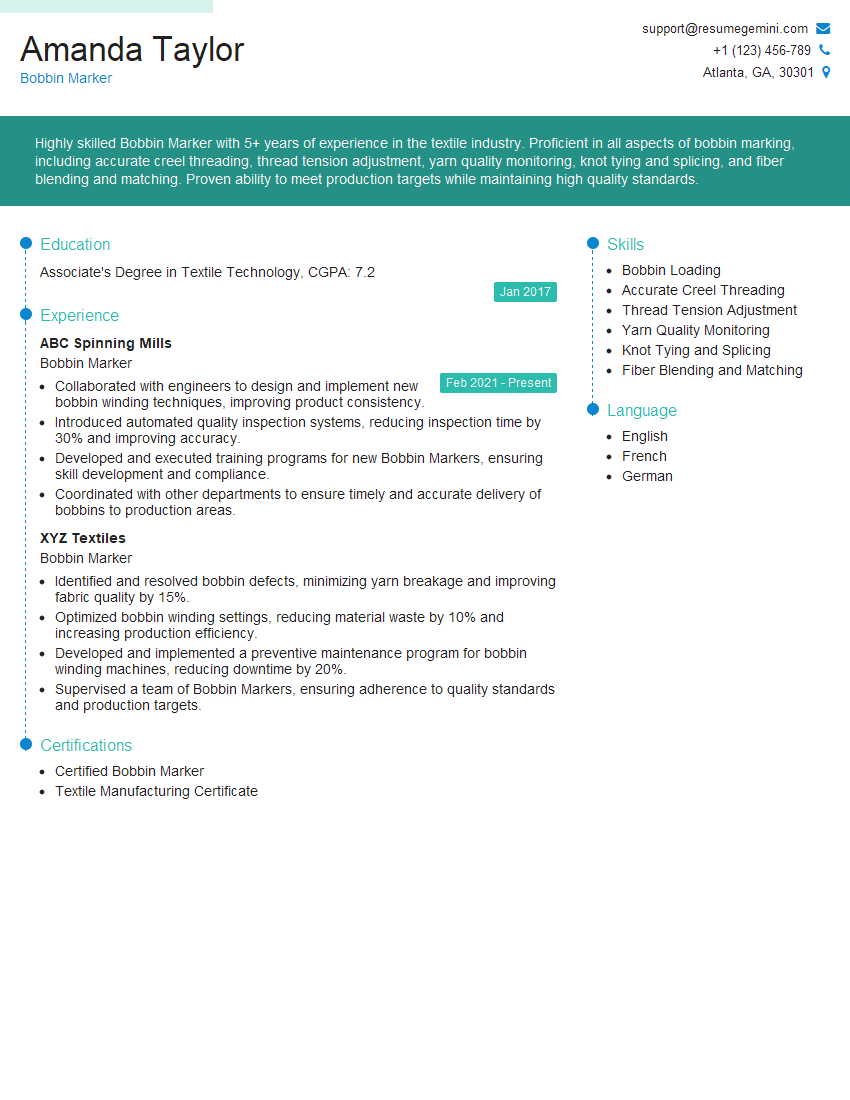

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bobbin Marker

1. What are the key technical skills required to excel as a Bobbin Marker?

The key technical skills required to excel as a Bobbin Marker include:

- In-depth understanding of bobbin winding machinery and their operations.

- Excellent knowledge of bobbin design and specifications.

- Experience in handling and inspecting yarn and thread.

- Proficient in setting up, calibrating, and operating bobbin winding machines.

- Ability to monitor and adjust winding parameters to ensure proper bobbin formation.

2. Can you describe the quality control procedures involved in Bobbin Marking?

Maintaining Yarn Tension

- Monitoring yarn tension throughout the winding process.

- Adjusting tension settings to optimize yarn quality and bobbin formation.

Checking Bobbin Dimensions

- Verifying bobbin dimensions meet specifications.

- Using precision measuring instruments to ensure accuracy.

Inspecting Yarn Lay

- Examining the uniformity and consistency of yarn lay on the bobbin.

- Identifying and correcting any defects or irregularities.

3. What are the common challenges faced by Bobbin Markers and how do you overcome them?

Common challenges faced by Bobbin Markers include:

- Yarn Breakage: Adjusting tension settings, checking yarn quality, and ensuring proper machine setup to minimize yarn breakage.

- Bobbin Deformation: Optimizing winding parameters, using the correct bobbin type, and adjusting machine settings to prevent bobbin deformation.

- Uneven Yarn Lay: Adjusting winding speed, tension, and machine settings to achieve an even and consistent yarn lay.

- Defective Yarn: Identifying and removing defective yarn before winding to prevent bobbin quality issues.

4. How do you ensure the safety and efficiency of the bobbin winding process?

- Safety: Following proper operating procedures, wearing appropriate safety gear, and maintaining a clean and organized work area.

- Efficiency: Optimizing machine settings, reducing downtime, and implementing lean manufacturing techniques to enhance productivity.

5. What is the role of automation in Bobbin Marking and how has it impacted the industry?

- Increased Productivity: Automated winding machines operate at faster speeds and with higher precision, resulting in increased bobbin production.

- Reduced Labor Costs: Automation eliminates the need for manual labor, reducing labor costs and increasing profitability.

- Improved Quality: Automated machines ensure consistent winding parameters, leading to improved bobbin quality and reduced defects.

6. Can you explain the different types of Bobbin Winders and their applications?

- Shuttle Bobbin Winders: Used for producing bobbins for shuttle looms. They create a tight and dense winding pattern.

- Cheese Bobbin Winders: Produce cylindrical bobbins with a large capacity for yarn storage. Used in various textile processes.

- Cone Bobbin Winders: Create conical bobbins used in knitting and embroidery machines. They provide a smooth and controlled yarn feed.

7. What are the key performance indicators (KPIs) used to measure Bobbin Marker productivity and efficiency?

- Bobbins Produced per Hour

- Bobbin Quality (Defects per Million)

- Machine Uptime

- Downtime Analysis

- Waste and Scrap Reduction

8. How do you stay up-to-date with the latest advancements in Bobbin Marking technology?

- Attending industry trade shows and conferences.

- Reading technical journals and industry publications.

- Participating in online forums and discussion groups.

- Networking with other professionals in the field.

9. Can you describe a time when you successfully resolved a complex Bobbin Marking issue?

In one instance, we encountered a problem with excessive yarn breakage during the winding process. After thoroughly analyzing the situation, I identified that the tension settings were incorrect and the yarn was not being properly wound onto the bobbin. By adjusting the tension settings and reconfiguring the machine, I was able to resolve the issue and optimize the bobbin winding process, resulting in reduced yarn breakage and improved bobbin quality.

10. Why are you interested in this Bobbin Marker position, and how do you believe your skills align with our company’s needs?

I am eager to join your company as a Bobbin Marker because I am passionate about the textile industry and have a strong foundation in Bobbin Marking techniques and machinery. My expertise in operating and maintaining bobbin winding machines, coupled with my commitment to quality and efficiency, make me a valuable asset to your team. Furthermore, I am confident that my drive to stay updated with industry advancements and my ability to resolve complex issues will enable me to make significant contributions to your company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bobbin Marker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bobbin Marker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bobbin Markers are responsible for ensuring that yarn is properly placed on bobbins, which are then used in textile manufacturing. Their key job responsibilities include:

1. Preparing bobbins

Bobbin Markers prepare bobbins by winding yarn onto them. They must ensure that the yarn is evenly distributed and there are no knots or tangles.

2. Marking bobbins

Once the bobbins are wound, Bobbin Markers mark them with the correct identification information. This information may include the yarn type, color, and weight.

3. Inspecting bobbins

Bobbin Markers inspect bobbins to ensure that they are free of defects. They check for any broken or damaged yarn, uneven winding, or incorrect marking.

4. Maintaining equipment

Bobbin Markers are responsible for maintaining the equipment they use. This may include cleaning and lubricating machines, and replacing worn parts.

Interview Preparation Tips

To help you ace your interview for a Bobbin Marker position, here are some preparation tips:

1. Research the company and the position

Take the time to learn about the company you are applying to and the specific Bobbin Marker position. This will help you better understand the company’s culture and the expectations for the role.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance.

3. Be prepared to talk about your experience

The interviewer will likely ask you about your previous work experience. Be prepared to discuss your skills and accomplishments, and how they relate to the Bobbin Marker position.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual attire such as jeans or sneakers.

5. Be confident and enthusiastic

The interviewer will be looking for someone who is confident and enthusiastic about the position. Be sure to make eye contact, smile, and speak clearly and confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bobbin Marker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!