Are you gearing up for a career in Body Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Body Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

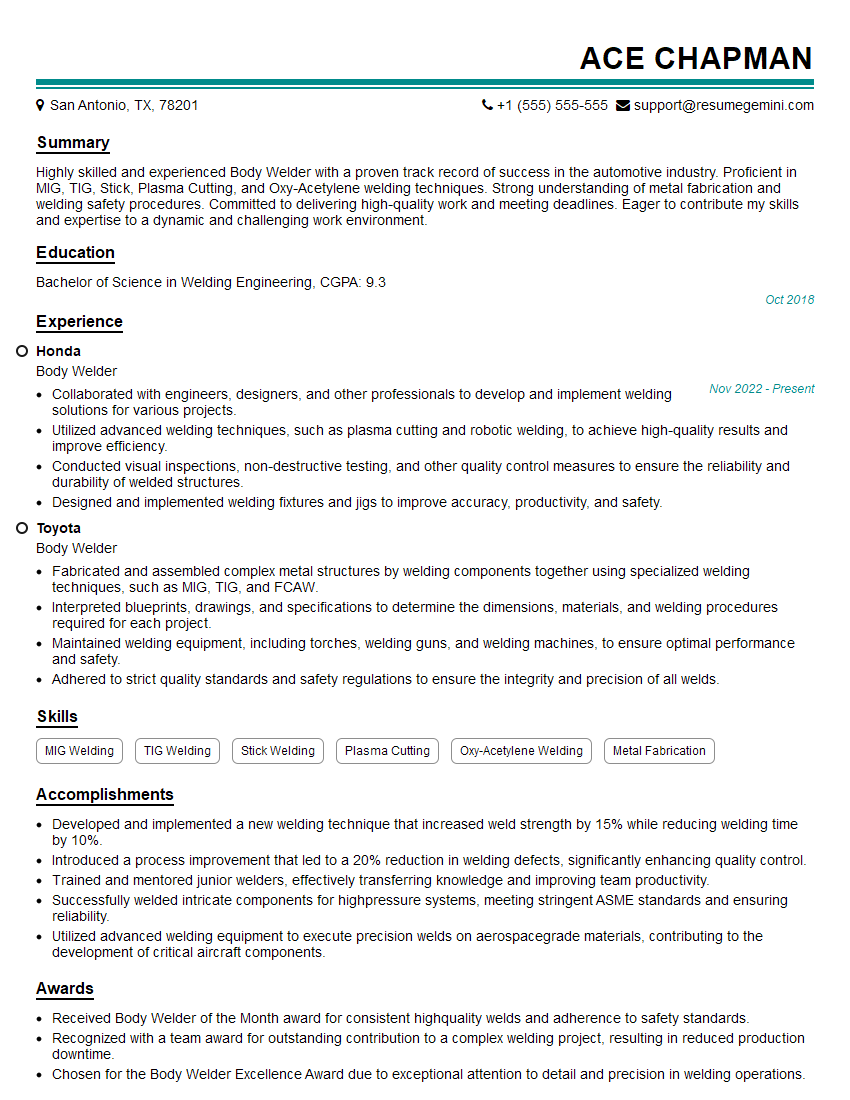

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Body Welder

1. Describe the different welding processes you are familiar with?

• Gas Tungsten Arc Welding (GTAW)

• Gas Metal Arc Welding (GMAW)

• Flux-Cored Arc Welding (FCAW)

• Shielded Metal Arc Welding (SMAW)

2. What are the important factors to consider when selecting the appropriate welding process for a given application?

Material thickness:

- GTAW is suitable for thin materials.

- GMAW and FCAW can be used for various material thicknesses.

- SMAW is effective for thicker materials.

Joint design:

- GTAW is ideal for precise and clean welds.

- GMAW and FCAW offer high deposition rates for butt and edge joints.

- SMAW is suitable for applications where accessibility is limited.

Welding Environment:

- GTAW can be used in various environments.

- GMAW and FCAW require shielding gases for protection.

- SMAW can be used outdoors with proper precautions.

3. How do you ensure the quality of your welds?

- Visual inspection for proper bead profile and penetration

- Dimensional measurements to meet specifications

- Non-destructive testing methods such as radiography and ultrasonic testing

- Adherence to welding procedures and codes

4. What types of welding defects have you encountered and how do you mitigate them?

- Porosity: caused by trapped gases, mitigated by proper shielding and gas flow

- Undercut: excessive penetration at the weld edges, mitigated by adjusting welding parameters

- Cold lap: incomplete fusion between layers, mitigated by proper joint preparation and heat input

- Cracking: caused by residual stresses, mitigated by preheating, post-weld heat treatment, and proper welding sequence

5. How do you stay updated on the latest welding technologies and techniques?

- Attending industry conferences and seminars

- Reading technical journals and publications

- Participating in online forums and discussions

- Seeking certifications and training

6. Describe your experience in working with different types of metals and alloys?

• Carbon steel

• Stainless steel

• Aluminum

• Titanium

• Inconel

7. How do you handle welding in challenging environments, such as high temperatures or confined spaces?

- Use appropriate personal protective equipment (PPE)

- Consider ventilation and cooling systems

- Plan for proper access and ergonomics

- Follow safety protocols and industry best practices

8. What is your understanding of welding codes and standards?

- American Welding Society (AWS) D1.1: Structural Welding Code – Steel

- AWS D17.1: Structural Welding Code – Aluminum

- American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- International Organization for Standardization (ISO) 3834: Quality Requirements for Fusion Welding of Metallic Materials

9. How do you approach welding projects that require precision and attention to detail?

- Careful planning and preparation

- Precise measuring and fitting

- Proper joint design and preparation

- Use of specialized equipment and techniques

10. Describe a complex welding project you have worked on and the challenges you faced.

- Project description: Welding a large-scale aluminum structure

- Challenges: Maintaining precision over long weld lengths, minimizing distortion, and meeting strict quality standards

- Solutions: Careful planning, use of jigs and fixtures, and advanced welding techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Body Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Body Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Body Welders play a pivotal role in the manufacturing industry, ensuring the structural integrity and durability of various metal components and assemblies. Their key responsibilities encompass:

1. Welding Operations

Perform various welding techniques such as gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and shielded metal arc welding (SMAW).

- Prepare and assemble metal parts according to blueprints and specifications.

- Set up and operate welding equipment, adjusting settings to achieve optimal weld quality.

2. Fabrication and Assembly

Fabricate and assemble metal components, including frames, chassis, and other structural elements.

- Cut, bend, and shape metal parts using hand tools and power equipment.

- Follow assembly procedures to join components securely and meet tolerance requirements.

3. Quality Control

Inspect and test welded joints to ensure they meet quality standards and specifications.

- Use visual inspection, non-destructive testing methods, and specialized tools to detect any defects.

- Document and report any issues to ensure timely remediation.

4. Safety and Compliance

Adhere to safety regulations and standards, ensuring a safe work environment and compliance with industry guidelines.

- Wear appropriate personal protective equipment (PPE), including welding masks, gloves, and flame-resistant clothing.

- Maintain a clean and organized work area, free of tripping hazards and potential fire sources.

Interview Tips

Preparing thoroughly for a Body Welder interview can significantly increase your chances of success. Consider these tips to enhance your interview performance:

1. Research the Company and Position

Before the interview, diligently research the company and the specific Body Welder position you are applying for. This will demonstrate your keen interest and understanding of the role.

- Visit the company’s website to learn about its history, mission, values, and products.

- Review the job description thoroughly, paying attention to the responsibilities, qualifications, and required skills.

2. Practice Your Welding Skills

Since welding is a hands-on skill, it is beneficial to practice your techniques before the interview if possible. This will help you feel confident and showcase your abilities.

- Set up a welding station in a safe and well-ventilated area.

- Practice welding on scrap metal to refine your technique and prepare for any welding tests during the interview.

3. Prepare Example Stories

During the interview, you may be asked about your experiences and skills relevant to the Body Welder role. Prepare specific examples of your work to highlight your qualifications.

- Describe instances where you successfully solved welding problems or improved welding efficiency.

- Provide examples of projects you have worked on that showcase your welding skills and attention to detail.

4. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic demeanor. Show the interviewer that you are genuinely interested in the position and excited about the prospect of joining the company.

- Dress professionally and arrive punctually for the interview.

- Be respectful and listen attentively to the interviewer’s questions and instructions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Body Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!