Are you gearing up for an interview for a Boiler Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Boiler Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

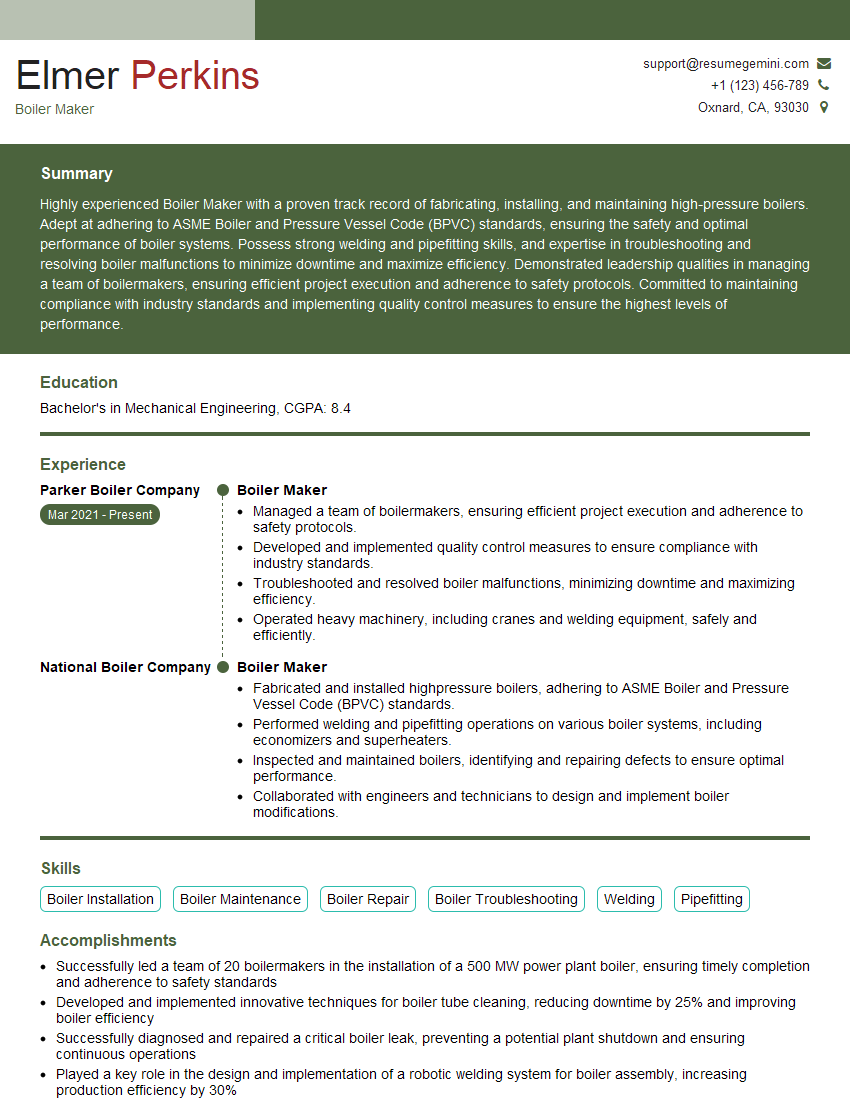

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boiler Maker

1. What types of boilers have you worked on, and which one do you have the most experience with?

In my career, I have worked on various types of boilers, including water tube boilers, fire tube boilers, and electric boilers. Out of these, I have the most experience with water tube boilers, having worked on them for over 5 years. During this time, I have gained expertise in installing, maintaining, and troubleshooting these boilers.

2. What is your process for troubleshooting a boiler that is not producing steam?

Analyze symptoms:

- Check boiler pressure

- Inspect fuel supply

- Examine water level

Identify potential causes:

- Faulty pressure gauge

- Clogged fuel line

- Leaking water valve

Implement solutions:

- Replace faulty gauge

- Clean fuel line

- Repair or replace leaking valve

3. What are the key safety procedures to follow when working on a boiler?

- Wear appropriate PPE

- Isolate boiler from power and fuel

- Allow boiler to cool before starting work

- Bleed off any residual pressure

- Follow manufacturer’s instructions carefully

4. What are the common causes of boiler tube failure?

- Overheating

- Corrosion

- Mechanical stress

- Manufacturing defects

- Improper water treatment

5. How do you maintain the efficiency of a boiler system?

- Regular cleaning and inspections

- Optimizing fuel-air ratio

- Monitoring and controlling water chemistry

- Using energy-saving technologies

- Performing preventative maintenance

6. What is the purpose of boiler feedwater treatment, and what are the different methods used?

Boiler feedwater treatment aims to remove impurities and dissolved solids from water to prevent corrosion, scale formation, and other issues within the boiler system. Various methods are employed, such as:

- Chemical treatment (using chemicals like sodium phosphate)

- Ion exchange (using resins to remove ions)

- Reverse osmosis (using a semi-permeable membrane to separate impurities)

- Degasification (removing dissolved gases like oxygen)

7. Explain the operation of a superheater in a boiler system.

A superheater is a heat exchanger used to increase the temperature of steam produced by a boiler. It consists of tubes located in the boiler’s hottest zone where hot gases from the combustion process transfer heat to the steam, raising its temperature above the saturation point.

8. What is the difference between a riveted boiler and a welded boiler?

- Riveted boiler: Plates are joined together using rivets, creating a leak-resistant seam. Requires regular inspection and maintenance of rivets.

- Welded boiler: Plates are joined using welding techniques, providing a stronger and more durable bond. Less maintenance required compared to riveted boilers.

9. Describe the process of hydrostatically testing a boiler.

- Fill boiler with water

- Apply pressure to the water

- Inspect for leaks, cracks, or deformations

- Release pressure and drain water

- Inspect internal components for any signs of damage

10. What is your experience with boiler water chemistry monitoring and control?

I am proficient in monitoring and controlling boiler water chemistry to prevent corrosion, scale formation, and other issues. I regularly perform water testing, analyze results, and adjust chemical treatment as needed. I use industry-standard methods and equipment, ensuring compliance with regulatory requirements and optimal boiler performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boiler Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boiler Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boilermakers are highly skilled tradespeople responsible for constructing, installing, and repairing boilers, pressure vessels, and other related equipment. Their job requires expertise in welding, fabrication, and metalworking techniques.

1. Fabrication and Assembly

Boilermakers fabricate and assemble various boiler components, including tubes, drums, and headers, using advanced welding techniques such as TIG, MIG, and stick welding. They ensure accurate assembly and precise fit of components.

- Interpret blueprints and follow specifications.

- Cut, shape, and weld boiler components using specialized equipment.

- Assemble boiler components, ensuring proper alignment and tightness.

2. Installation and Erection

Boilermakers install and erect boilers and related equipment at industrial facilities and power plants. They work in collaboration with engineers and construction teams to ensure proper placement and secure installation.

- Prepare installation sites and position boiler components.

- Assemble and connect boiler components, pipes, and fittings.

- Install insulation, lagging, and other accessories.

3. Maintenance and Repair

Boilermakers perform routine maintenance and repairs on boilers and pressure vessels to ensure their safe and efficient operation. They use diagnostic tools to identify problems and carry out repairs using welding and fabrication techniques.

- Conduct inspections and diagnose boiler malfunctions.

- Repair or replace boiler tubes, drums, and other components.

- Perform routine maintenance and cleaning procedures.

4. Safety and Regulations

Boilermakers adhere strictly to safety regulations and industry standards. They follow proper welding practices, use appropriate safety equipment, and maintain a clean and organized work environment to minimize hazards.

- Comply with safety codes and regulations.

- Use personal protective equipment and follow safe work practices.

- Maintain a clean and hazard-free work area.

Interview Tips

Preparing thoroughly for a Boiler Maker interview can significantly increase your chances of success. Here are some essential tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, industry, and specific requirements for the Boiler Maker position. This demonstrates your genuine interest and preparedness.

- Visit the company website and review their mission statement, services, and recent news.

- Research the industry trends and key players to understand the company’s position.

- Thoroughly read the job description and identify the essential skills and qualifications.

2. Highlight Your Skills and Experience

Emphasize your welding, fabrication, and metalworking skills. Provide specific examples of projects you have worked on that demonstrate your abilities in boiler fabrication, installation, and repair.

- Quantify your accomplishments using specific numbers and metrics.

- Prepare examples of projects where you solved problems or overcame challenges.

- Practice describing your experience using the “STAR” method (Situation, Task, Action, Result).

3. Be Prepared to Discuss Safety

Boilermakers work in a hazardous environment, so it is crucial to demonstrate your commitment to safety. Explain your understanding of safety protocols and your experience in following them.

- Emphasize your adherence to industry standards and regulations.

- Discuss your experience in using personal protective equipment (PPE) and safe work practices.

- Highlight your ability to identify and mitigate potential hazards.

4. Ask Insightful Questions

At the end of the interview, asking insightful questions shows your enthusiasm and curiosity about the position and the company. Prepare questions that demonstrate your interest in the company’s operations, industry trends, and growth opportunities.

- Ask about the company’s future projects or expansion plans.

- Inquire about opportunities for professional development and training.

- Seek insights into the company’s safety culture and procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Boiler Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Boiler Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.