Are you gearing up for a career in Boiler Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Boiler Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

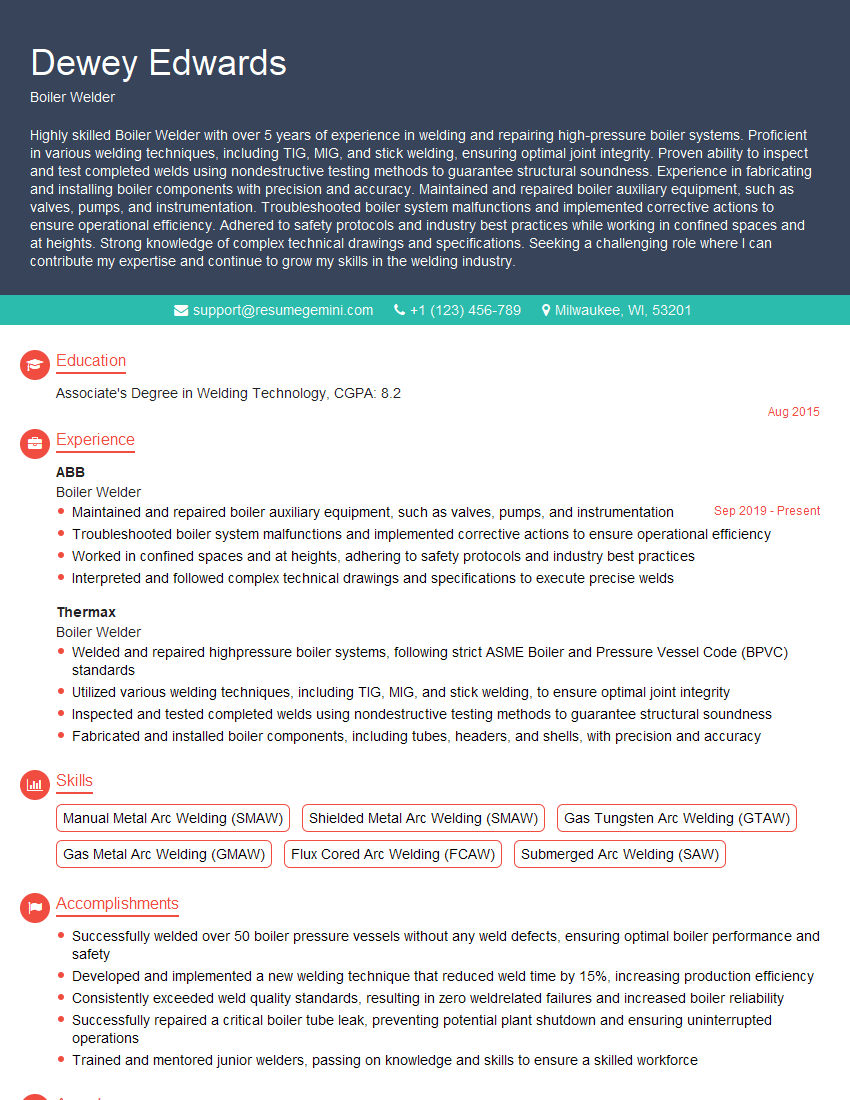

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boiler Welder

1. Describe the main steps involved in welding a boiler?

- Prepare the work area and gather the necessary tools and materials.

- Clean and inspect the boiler to ensure it is free of any defects or damage.

- Cut and fit the boiler components together, ensuring that they are properly aligned and secured.

- Tack weld the components together to hold them in place.

- Weld the components together using the appropriate welding technique and materials.

- Inspect the weld to ensure it is of high quality and meets the required standards.

- Grind and polish the weld to remove any excess material or imperfections.

- Test the boiler to ensure it is leak-free and functioning properly.

2. What are the different welding positions you are proficient in?

- Flat position: This is the most common welding position and involves welding on a flat surface.

- Horizontal position: This position involves welding on a horizontal surface, such as a pipe or tube.

- Vertical position: This position involves welding on a vertical surface, such as a wall or tank.

- Overhead position: This position involves welding on a surface that is above the welder’s head, such as a ceiling.

3. What safety precautions should be taken when welding a boiler?

- Wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing.

- Ensure the work area is well-ventilated to avoid exposure to harmful fumes.

- Use proper welding techniques and equipment to minimize the risk of accidents.

- Follow all safety procedures and guidelines established by the company or industry standards.

- Be aware of the potential hazards of welding, such as fire, explosions, and electrical shock.

4. What are the common problems you have encountered while welding boilers and how did you resolve them?

- Problem: Weld cracking

- Solution: Use a different welding technique or materials, or preheat the metal before welding.

- Problem: Weld porosity

- Solution: Clean the metal before welding and use a shielding gas to prevent oxygen from entering the weld.

- Problem: Weld distortion

- Solution: Use appropriate welding techniques and sequencing to minimize distortion, or use a jig or fixture to hold the metal in place.

5. What types of welding equipment are you familiar with?

- Arc welding equipment, including stick welders, TIG welders, and MIG welders.

- Oxy-fuel welding equipment, including torches and regulators.

- Plasma cutting equipment.

- Laser welding equipment.

6. How do you stay up-to-date with the latest welding technologies and techniques?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Participate in online forums and discussions.

- Seek out opportunities to work with experienced welders and learn from their expertise.

7. What are the different types of welding joints used in boiler construction?

- Butt joint: This is a joint where two pieces of metal are joined together end-to-end.

- Edge joint: This is a joint where two pieces of metal are joined together along their edges.

- T-joint: This is a joint where one piece of metal is joined to the edge of another piece of metal.

- Corner joint: This is a joint where two pieces of metal are joined together at a right angle.

8. What is the importance of preheating and post-heating when welding boilers?

- Preheating: This helps to reduce the risk of weld cracking by reducing the thermal stresses in the metal.

- Post-heating: This helps to relieve any residual stresses in the weld and improve its overall strength and toughness.

9. What is the difference between a weld symbol and a welding procedure specification (WPS)?

- Weld symbol: This is a graphical representation of a weld joint, which indicates the type of weld, the dimensions of the weld, and the location of the weld.

- Welding procedure specification (WPS): This is a document that provides detailed instructions on how to perform a specific welding operation, including the welding process, the welding parameters, and the materials to be used.

10. How do you ensure the quality of your welds?

- Follow all welding procedures and specifications.

- Use high-quality welding materials.

- Inspect welds visually and using non-destructive testing methods.

- Continuously improve my welding skills and knowledge.

- Seek feedback from experienced welders and supervisors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boiler Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boiler Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boiler Welders are responsible for welding and fabricating boilers and other pressure vessels. They must have a strong understanding of welding techniques and safety regulations. Key job responsibilities include:

1. Welding and Fabrication

Boiler Welders use various welding techniques to join metal components, including:

- Arc welding

- Gas welding

- Resistance welding

2. Material Handling

Boiler Welders must be able to handle heavy materials, including metal plates, pipes, and rods. They must also be able to work in confined spaces.

3. Inspection and Testing

Boiler Welders must inspect their work to ensure that it meets quality standards. They must also test welds to ensure that they are strong and leak-proof.

4. Maintenance and Repair

Boiler Welders may also be responsible for maintaining and repairing boilers and other pressure vessels. This may involve welding, patching, or replacing damaged components.

Interview Tips

Preparing for an interview can be a daunting task, but following these tips can help you ace the interview

1. Research the Company and Position

Take the time to learn about the company and the position you are applying for. This will help you answer questions intelligently and show that you are genuinely interested in the opportunity.

2. Practice Your Answers

Think about the common interview questions you are likely to be asked and practice your answers. This will help you feel more confident and prepared during the interview.

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or business casual attire.

4. Be Punctual

Arrive for your interview on time. Punctuality shows that you are respectful of the interviewer’s time.

5. Be Yourself

The most important thing is to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boiler Welder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.