Are you gearing up for a career in Boilermaker Apprentice? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Boilermaker Apprentice and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

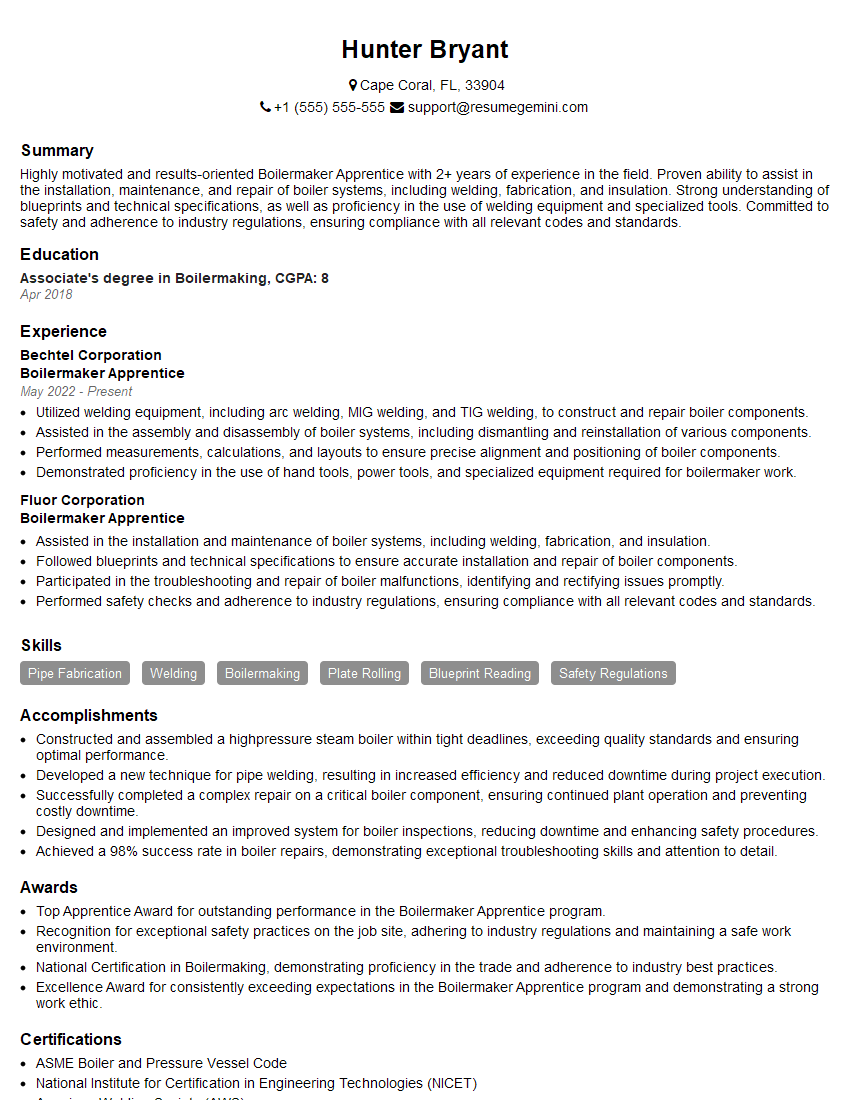

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boilermaker Apprentice

1. Explain the process of laying out and fabricating a boiler pressure part?

As a Boilermaker Apprentice, I would follow these steps to lay out and fabricate a boiler pressure part:

- Read and interpret the engineering drawings to determine the specifications of the part.

- Select the appropriate materials and tools for the job.

- Lay out the part on the material using measuring tools and marking devices.

- Cut the material to the desired shape using cutting tools such as shears, saws, or plasma cutters.

- Form the material into the desired shape using bending, rolling, or pressing techniques.

- Weld the components together using appropriate welding techniques.

- Inspect the finished part to ensure it meets the required specifications.

2. Describe the different types of welding processes used in boilermaking and their applications?

Arc Welding

- Shielded Metal Arc Welding (SMAW): Uses coated electrodes to create an electric arc between the electrode and the base metal. Suitable for a wide range of metals and thicknesses.

- Gas Metal Arc Welding (GMAW): Uses a continuously fed wire electrode and shielding gas to create an electric arc. Ideal for thin materials and high-speed welding.

- Gas Tungsten Arc Welding (GTAW): Uses a tungsten electrode and shielding gas to create an electric arc. Provides high-quality welds but requires skilled operators.

Other Welding Processes

- Oxy-fuel Welding: Uses a mixture of oxygen and fuel gas to create a flame for welding. Suitable for thicker materials.

- Plasma Arc Cutting: Uses a plasma torch to cut and weld metals. Provides precise and clean cuts.

3. How do you ensure the quality of your welds?

I ensure the quality of my welds by following these practices:

- Properly preparing the joint surfaces by cleaning and removing any contaminants.

- Selecting the correct welding process and parameters for the materials being welded.

- Using appropriate welding techniques to minimize defects such as porosity, slag inclusions, and undercut.

- Inspecting the welds visually and using non-destructive testing methods such as dye penetrant testing or ultrasonic testing to identify any potential flaws.

- Continuously improving my welding skills through training and practice.

4. Describe the importance of safety in boilermaking and the precautions you take to minimize risks?

Safety is paramount in boilermaking. I take the following precautions to minimize risks:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a welding helmet.

- Ensuring the work area is well-ventilated and free from tripping hazards.

- Using proper lifting techniques to avoid injuries.

- Following established safety protocols and procedures.

- Being aware of potential hazards such as electrical shock, burns, and falling objects.

- Regularly inspecting tools and equipment to ensure they are in good working condition.

5. How do you stay up-to-date with advancements in boilermaking technologies and techniques?

I stay up-to-date with advancements in boilermaking technologies and techniques through the following methods:

- Attending industry conferences and workshops.

- Reading trade publications and technical journals.

- Participating in online forums and discussion groups.

- Consulting with experienced boilermakers and engineers.

- Undertaking formal training programs.

- Being open to learning new technologies and adapting to changing industry standards.

6. How do you handle working under pressure and tight deadlines?

When working under pressure and tight deadlines, I employ the following strategies:

- Prioritizing tasks and focusing on the most critical ones first.

- Breaking down large projects into smaller, manageable tasks.

- Communicating effectively with colleagues and supervisors to ensure everyone is on the same page.

- Staying organized and keeping track of my progress.

- Taking breaks when needed to maintain focus and avoid mistakes.

- Seeking support and guidance from experienced team members when necessary.

7. Describe a challenging project you worked on and how you overcame the obstacles you faced?

Project Description

I worked on a project to fabricate and install a large boiler pressure vessel for a power plant. The vessel was complex in design and required precise welding and assembly.

Obstacles

- Tight deadlines and a demanding schedule.

- Limited access to some areas of the vessel during welding.

- Challenging welding techniques required for certain joints.

How I Overcame the Obstacles

- Collaborated with the team to develop a detailed plan and timeline.

- Used specialized welding equipment and techniques to access difficult areas.

- Sought guidance from senior boilermakers and engineers to optimize welding procedures.

- Communicated regularly with the client to keep them informed of our progress and any potential delays.

Outcome

Despite the challenges, we successfully fabricated and installed the boiler pressure vessel on time and to the required specifications.

8. Why are you interested in working as a Boilermaker Apprentice for our company?

I am eager to join your company as a Boilermaker Apprentice because:

- Your company is a recognized leader in the industry, known for its commitment to quality and safety.

- The apprenticeship program offers a structured path for me to develop the skills and knowledge required to become a proficient boilermaker.

- I am impressed by your company’s focus on employee development and training.

- I believe that my skills and experience would be a valuable asset to your team.

- I am eager to contribute to the success of your company and grow my career in the boilermaking industry.

9. What are your salary expectations for this role?

My salary expectations are commensurate with the industry standards for Boilermaker Apprentices with my level of experience and qualifications. I am confident that I can quickly become a valuable member of your team and make significant contributions to your company.

10. Do you have any questions for us about the role or the company?

I would like to know more about the specific projects that the company is currently working on and the opportunities for professional development within the apprenticeship program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boilermaker Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boilermaker Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boilermaker Apprentices perform a variety of tasks in the fabrication, assembling, repairs, and maintenance of boilers and other types of pressure vessels. Other typical responsibilities include:

1. Working with various materials

Boilermaker Apprentices work with a variety of materials, including steel, stainless steel, aluminum, and copper. They cut, shape, and weld these materials using a variety of tools and techniques.

- Using hand tools, power tools, and welding equipment

- Fabricate boiler components such as drums, shells, and tubes

2. Reading and interpreting blueprints

Boilermaker Apprentices must be able to read and interpret blueprints in order to fabricate and assemble boilers and other pressure vessels.

- Follow blueprints and specifications to ensure accuracy and quality

- Inspect completed work to ensure it meets required standards

3. Safety and environmental regulations

Boilermaker Apprentices must be aware of and follow all safety and environmental regulations. They must wear appropriate personal protective equipment and follow safe work practices.

- Adhere to safety protocols and regulations

- Maintain a clean and organized work environment

4. Teamwork and customer service

Boilermaker Apprentices often work as part of a team, so they must be able to work well with others. They must also be able to provide good customer service.

- Collaborate with other Boilermakers and support staff

- Interact with clients and provide updates on project progress

Interview Tips

Preparing for your Boilermaker Apprentice interview can increase your chances of landing the job. Here are a few tips to help you make a good impression:

1. Research the company and the position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you answer questions intelligently and show that you’re genuinely interested in the opportunity.

- Visit the company website

- Read articles about the company

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions

- Highlight your skills and experience that are most relevant to the position

- Be prepared to talk about your strengths and weaknesses

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early, to show that you’re respectful of the interviewer’s time.

- Wear a suit or business casual attire

- Be clean and well-groomed

- Make eye contact and smile

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic and positive about the opportunity. Show the interviewer that you’re excited about the possibility of working for the company and that you’re confident in your abilities.

- Be genuine and authentic

- Share your passion for the industry

- Be prepared to talk about your goals and aspirations

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boilermaker Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.