Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Boilermaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

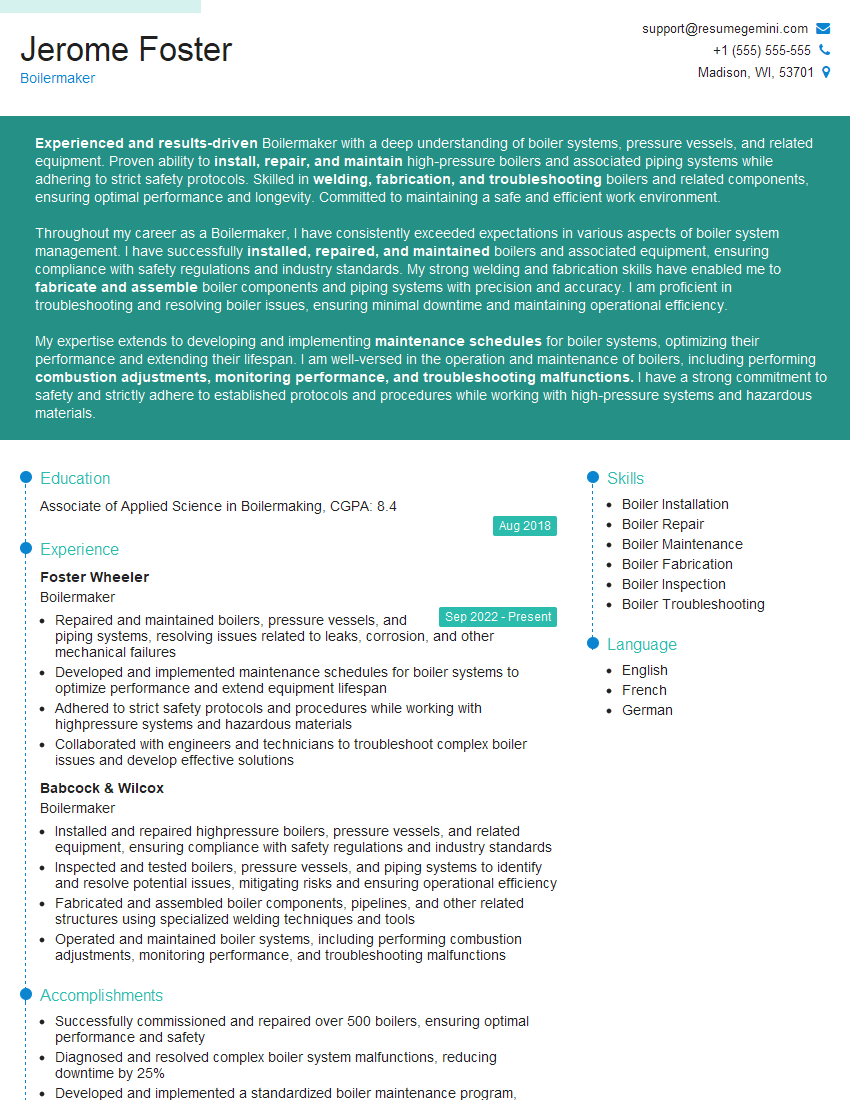

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boilermaker

1. Briefly describe the safety precautions you take while working as a Boilermaker?

As a Boilermaker, safety is paramount. I adhere to all established safety protocols and regulations, including:

- Wearing appropriate personal protective equipment (PPE), such as flame-resistant clothing, gloves, hard hat, and safety glasses.

- Inspecting equipment and tools before use to ensure they are in good working condition.

- Following proper lockout/tagout procedures to prevent accidental energy release.

- Maintaining a clean and organized work area free of tripping hazards and clutter.

- Working with colleagues to maintain a safe working environment and reporting any potential hazards promptly.

2. Explain the different types of boilers and their respective applications?

- Fire-tube boilers: These boilers have a firebox surrounded by water-filled tubes. The hot gases from the firebox pass through the tubes, heating the water and creating steam.

- Water-tube boilers: In these boilers, water flows through tubes surrounded by hot gases. The heated water turns into steam, which is then collected in a drum.

- Package boilers: These are self-contained units that include the boiler, burner, and controls. They are typically used in smaller applications.

- Industrial boilers: These are large boilers used in power plants and other industrial settings. They produce high-pressure steam for various processes.

3. Describe the various welding techniques used in boilermaking and their advantages and disadvantages?

In boilermaking, we commonly use the following welding techniques:

- Arc welding (SMAW, GMAW, FCAW): These methods use an electric arc to melt the metal and create a weld. They offer high-quality welds and are suitable for different materials.

- Gas welding (OAW): This technique uses a fuel gas (usually acetylene) and oxygen to create a flame that melts the metal. It provides precise control and is often used for thin materials.

- Tig welding (GTAW): This process uses a tungsten electrode and an inert gas to create a weld. It offers high-quality, clean welds and is suitable for various metals.

Advantages and Disadvantages of each method will be included in the actual answer provided by the candidate

4. What are the key considerations for selecting the appropriate materials for boiler construction?

When selecting materials for boiler construction, I consider several factors, including:

- Temperature and pressure requirements: The materials must withstand the high temperatures and pressures encountered in the boiler.

- Corrosion resistance: The materials must be resistant to corrosion caused by water, steam, and other chemicals.

- Weldability: The materials must be easily weldable to ensure the integrity of the boiler.

- Availability and cost: The materials must be readily available and cost-effective for the application.

5. How do you ensure the quality of welds in boilermaking?

To ensure the quality of welds in boilermaking, I follow these steps:

- Proper preparation: I prepare the metal surfaces by cleaning and beveling them to create a suitable joint.

- Welding process selection: I choose the appropriate welding technique based on the materials, thickness, and application.

- Weld execution: I use proper welding techniques, including controlling the speed, heat input, and welding angle.

- Non-destructive testing (NDT): I conduct NDT methods such as visual inspection, magnetic particle testing, or ultrasonic testing to ensure the integrity of the welds.

6. How do you interpret and follow engineering drawings and specifications for boilermaking projects?

To interpret and follow engineering drawings and specifications, I:

- Study the drawings carefully: I examine the dimensions, symbols, and notes to understand the design intent.

- Review specifications: I read the specifications to determine the requirements for materials, welding procedures, and other aspects.

- Plan the fabrication: I develop a fabrication plan based on the drawings and specifications.

- Coordinate with other trades: I communicate with other trades to ensure that my work aligns with the overall project.

7. Describe the maintenance procedures you typically perform on boilers?

To maintain boilers, I perform various tasks, including:

- Regular inspections: I inspect the boiler components, such as tubes, tubesheets, and pressure vessels, for any signs of wear or damage.

- Cleaning: I remove deposits from the boiler surfaces using chemical or mechanical methods.

- Replacement of components: I replace worn-out or damaged parts, such as tubes, gaskets, and valves.

- Adjustments: I adjust settings, such as fuel flow and air supply, to optimize boiler performance.

- Record keeping: I maintain records of maintenance activities and observations.

8. How do you troubleshoot common boiler problems?

When troubleshooting common boiler problems, I:

- Identify symptoms: I observe the boiler’s behavior and any abnormal sounds or indications.

- Check safety features: I verify that safety devices, such as pressure relief valves and flame sensors, are functioning properly.

- Inspect components: I examine potential problem areas, such as fuel lines, ignition systems, or water levels.

- Consult documentation: I refer to technical manuals and troubleshooting guides for additional insights.

- Resolve the issue: I implement appropriate solutions to fix the problem, such as cleaning components, replacing parts, or adjusting settings.

9. What measures do you take to ensure safety while working on boilers?

- Follow safety protocols: I adhere to all established safety regulations and procedures.

- Wear appropriate PPE: I wear protective gear, including gloves, safety glasses, and flame-resistant clothing.

- Lock out/tag out: I lock out and tag out energy sources before working on boilers.

- Test and inspect: I test and inspect safety devices regularly to ensure their functionality.

- Maintain a clean work area: I keep the work area free of clutter and potential hazards.

10. How do you stay updated on the latest advancements in boilermaking technologies and practices?

- Attend industry events and conferences: I participate in seminars and workshops to learn about new technologies and best practices.

- Read industry publications: I subscribe to trade magazines and journals to stay informed about the latest developments.

- Engage in online learning: I take online courses and webinars to enhance my knowledge and skills.

- Network with professionals: I connect with other boilermakers and experts to exchange ideas and learn from their experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boilermaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boilermaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boilermakers are skilled tradespeople who specialize in the construction, installation, repair, and maintenance of boilers and other high-pressure vessels. They ensure that these systems operate safely and efficiently, playing a vital role in various industries such as power generation, manufacturing, and petrochemicals.

1. Construction and Installation

Boilermakers construct and install new boilers and pressure vessels according to blueprints and specifications. They assemble and weld components, ensuring proper fit and alignment.

- Interpret blueprints and specifications to determine construction requirements

- Assemble and weld boiler components using specialized tools and techniques

- Install boilers and pressure vessels in compliance with safety regulations

2. Repair and Maintenance

Boilermakers perform regular maintenance and repairs on existing boilers and pressure vessels. They identify and fix leaks, cracks, and other issues to ensure optimal performance.

- Inspect boilers and pressure vessels for damage or wear

- Diagnose and repair leaks, cracks, and other defects

- Perform routine maintenance tasks to prevent breakdowns

3. Safety and Regulations

Boilermakers are responsible for ensuring the safe operation of boilers and pressure vessels. They adhere to strict safety regulations and industry standards.

- Follow safety protocols and wear appropriate personal protective equipment (PPE)

- Inspect boilers and pressure vessels for potential hazards

- Report any safety concerns to supervisors or authorities

4. Troubleshooting and Problem-Solving

Boilermakers must be able to troubleshoot and resolve technical issues that arise during construction, installation, or maintenance. They use their knowledge and experience to identify and rectify problems.

- Use diagnostic tools to identify the source of problems

- Develop and implement solutions to resolve technical issues

- Troubleshoot and repair electrical and mechanical systems

Interview Tips

To ace your Boilermaker interview, preparation is key. Here are some tips to help you stand out:

1. Research the Company and Position

Gather information about the company’s industry, size, and culture. Learn about the specific role you are applying for and its responsibilities.

- Visit the company’s website and social media pages

- Read industry news and articles

- Network with professionals in the field

2. Highlight Your Skills and Experience

In your resume and interview, focus on showcasing your technical skills, such as welding, fabrication, and boiler repair. Quantify your experience by providing specific examples of projects you have worked on.

- Prepare a portfolio of your work, if possible

- Be prepared to discuss your experience with blueprint reading and interpretation

- Emphasize your safety consciousness and adherence to industry regulations

3. Prepare for Technical Questions

Expect technical questions about boiler design, construction, and maintenance. Review your knowledge of boiler systems, including components, materials, and troubleshooting techniques.

- Study boiler codes and safety standards

- Practice answering questions on welding techniques

- Be familiar with different types of boilers and their applications

4. Demonstrate Your Problem-Solving Abilities

Boilermakers often encounter unexpected challenges on the job. In the interview, provide examples of how you have used problem-solving skills to resolve technical issues.

- Describe situations where you identified and fixed problems in boiler systems

- Explain your thought process and decision-making

- Show that you are proactive and take initiative to prevent problems

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boilermaker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!