Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Boilermaker Pipe Fitter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Boilermaker Pipe Fitter so you can tailor your answers to impress potential employers.

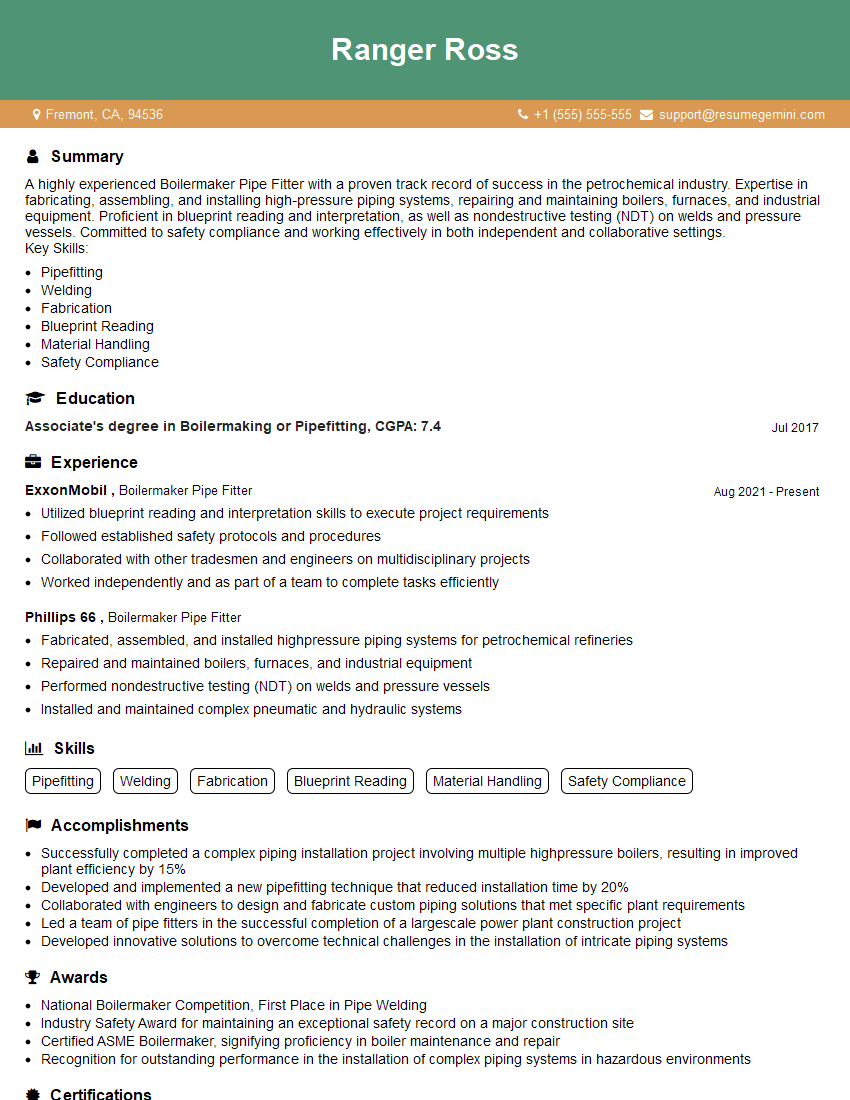

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boilermaker Pipe Fitter

1. What are the steps involved in bending a pipe?

The steps involved in bending a pipe are:

- Calculate the bend radius and the length of the pipe required for the bend.

- Cut the pipe to the required length.

- Mark the bend point on the pipe with a pipe bender.

- Heat the pipe at the bend point using a torch or heat gun.

- Bend the pipe using a pipe bender.

- Cool the pipe to room temperature.

2. What are the different types of pipe fittings?

The different types of pipe fittings are:

- Elbows: Elbows are used to change the direction of a pipe run.

- Tees: Tees are used to connect three pipes together.

- Crosses: Crosses are used to connect four pipes together.

- Reducers: Reducers are used to connect two pipes of different diameters.

- Caps: Caps are used to close the end of a pipe.

- Plugs: Plugs are used to temporarily close a hole in a pipe.

- Unions: Unions are used to connect two pipes together that can be easily disconnected.

3. What are the different types of welding processes used in pipefitting?

The different types of welding processes used in pipefitting are:

- Gas tungsten arc welding (GTAW): GTAW is a type of welding that uses a non-consumable tungsten electrode to create an arc between the electrode and the metal being welded. GTAW is often used for welding thin metals and for welding in difficult-to-reach areas.

- Gas metal arc welding (GMAW): GMAW is a type of welding that uses a consumable wire electrode that is melted by the arc and deposited into the weld joint. GMAW is often used for welding thick metals and for welding in high-production environments.

- Flux-cored arc welding (FCAW): FCAW is a type of welding that uses a consumable wire electrode that is filled with a flux. The flux is melted by the arc and produces a gas that protects the weld from contamination. FCAW is often used for welding in outdoor environments and for welding in areas where there is a lot of wind.

- Shielded metal arc welding (SMAW): SMAW is a type of welding that uses a consumable electrode that is coated with a flux. The flux is melted by the arc and produces a gas that protects the weld from contamination. SMAW is often used for welding in outdoor environments and for welding in areas where there is a lot of wind.

4. What are the safety precautions that must be taken when working with pipefitting tools and equipment?

The safety precautions that must be taken when working with pipefitting tools and equipment are:

- Wear appropriate personal protective equipment (PPE), such as a hard hat, safety glasses, earplugs, and gloves.

- Keep the work area clean and free of tripping hazards.

- Inspect tools and equipment before each use to ensure they are in good working condition.

- Use tools and equipment only for their intended purpose.

- Never operate tools or equipment while under the influence of drugs or alcohol.

- Be aware of your surroundings and be cautious of other workers.

5. What are the different types of materials that are used in pipefitting?

The different types of materials that are used in pipefitting are:

- Steel

- Copper

- PVC

- CPVC

- PE

- ABS

- PEX

6. What are the different types of pipe supports that are used in pipefitting?

The different types of pipe supports that are used in pipefitting are:

- Clevis hangers

- Spring hangers

- Rod hangers

- Beam clamps

- Strut clamps

- Roller supports

- Guide shoes

7. What are the different types of pipe insulations that are used in pipefitting?

The different types of pipe insulations that are used in pipefitting are:

- Fiberglass

- Polystyrene

- Polyethylene

- Rubber

- Cellular glass

8. What are the different types of pipe joints that are used in pipefitting?

The different types of pipe joints that are used in pipefitting are:

- Socket weld joints

- Butt weld joints

- Threaded joints

- Flanged joints

- Brazed joints

- Soldered joints

9. What are the different types of pipes that are used in pipefitting?

The different types of pipes that are used in pipefitting are:

- Welded pipes

- Seamless pipes

- Copper pipes

- PVC pipes

- CPVC pipes

- PE pipes

- ABS pipes

- PEX pipes

10. What are the different types of codes and standards that must be followed when working with pipefitting tools and equipment?

The different types of codes and standards that must be followed when working with pipefitting tools and equipment are:

- The American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code

- The American Petroleum Institute (API) Code for Unfired Pressure Vessels

- The National Fire Protection Association (NFPA) Standard for Fire and Smoke Control in Buildings

- The International Code Council (ICC) International Building Code

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boilermaker Pipe Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boilermaker Pipe Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Boilermaker Pipe Fitter is an expert in assembling, installing, and maintaining piping systems in various industrial settings. Their primary responsibilities encompass:

1. Pipe Fabrication and Assembly

Fabricating and assembling piping systems, including cutting, bending, welding, and fitting pipes according to specified blueprints and codes.

- Interpreting technical drawings and specifications to determine pipe sizes, materials, and fabrication requirements

- Cutting pipes using tools such as pipe cutters and power saws

- Bending pipes using bending machines or hand tools to create the required shapes and angles

- Welding pipes together using specialized welding techniques to ensure secure and leak-proof connections

- Fitting pipes and connecting them to valves, pumps, and other equipment using flanges, gaskets, and bolts

2. Pipe Installation

Installing piping systems in accordance with industry standards, ensuring proper alignment, support, and safety.

- Planning and coordinating the installation of piping systems in various facilities

- Positioning and aligning pipes using levels, plumb bobs, and measuring tools

- Securing pipes to walls, ceilings, and floors using brackets, clamps, and supports

- Connecting pipes to equipment and other piping components using flanges, unions, and couplings

- Testing piping systems for leaks and proper operation

3. Pipe Maintenance and Repair

Maintaining and repairing piping systems to ensure optimal performance, prevent leaks, and address any issues.

- Inspecting piping systems regularly for leaks, corrosion, and other signs of damage

- Troubleshooting and identifying the cause of problems in piping systems

- Repairing or replacing damaged pipes, valves, and fittings

- Performing routine maintenance tasks such as cleaning, lubricating, and adjusting valves

- Maintaining records of all maintenance and repair work performed

4. Adherence to Safety and Quality Standards

Complying with all applicable safety regulations and quality standards to ensure a safe working environment and high-quality workmanship.

- Wearing appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and gloves

- Following established safety protocols and procedures for working with hazardous materials

- Inspecting and testing piping systems to ensure they meet industry standards and specifications

- Maintaining a clean and organized work area to prevent accidents and ensure efficiency

- Adhering to all applicable codes and regulations for boilermaking and pipefitting

Interview Tips

To prepare effectively for your Boilermaker Pipe Fitter interview, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s background, industry, and current projects. This knowledge will help you demonstrate your interest and understanding of their business.

- Visit the company’s website and social media pages

- Read industry publications and news articles

- Attend industry events or webinars

2. Practice Your Technical Skills

Refresh your knowledge of pipefitting techniques, welding processes, and industry standards. Practice answering questions related to your technical abilities.

- Review blueprints and specifications

- Practice welding on different pipe materials

- Familiarize yourself with safety protocols and quality control procedures

3. Highlight Your Experience and Qualifications

Emphasize your relevant experience and qualifications, including your apprenticeship training, certifications, and previous projects. Quantify your accomplishments whenever possible.

- Describe your experience in pipe fabrication, installation, and maintenance

- Highlight your knowledge of different pipefitting materials and welding techniques

- Mention any relevant certifications or licenses you hold

4. Prepare for Behavioral Questions

Expect behavioral questions that assess your teamwork, problem-solving, and communication skills. Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Describe a time you faced a challenging technical problem and how you resolved it

- Discuss a time you worked effectively as part of a team to complete a project

- Explain how you handle pressure and meet deadlines

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Dress professionally and arrive on time. Be respectful and attentive to the interviewer’s questions and comments.

- Express your interest in the position and the company

- Ask thoughtful questions to demonstrate your engagement

- Thank the interviewer for their time and consideration

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Boilermaker Pipe Fitter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.