Are you gearing up for a career in Boilermaker Welder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Boilermaker Welder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

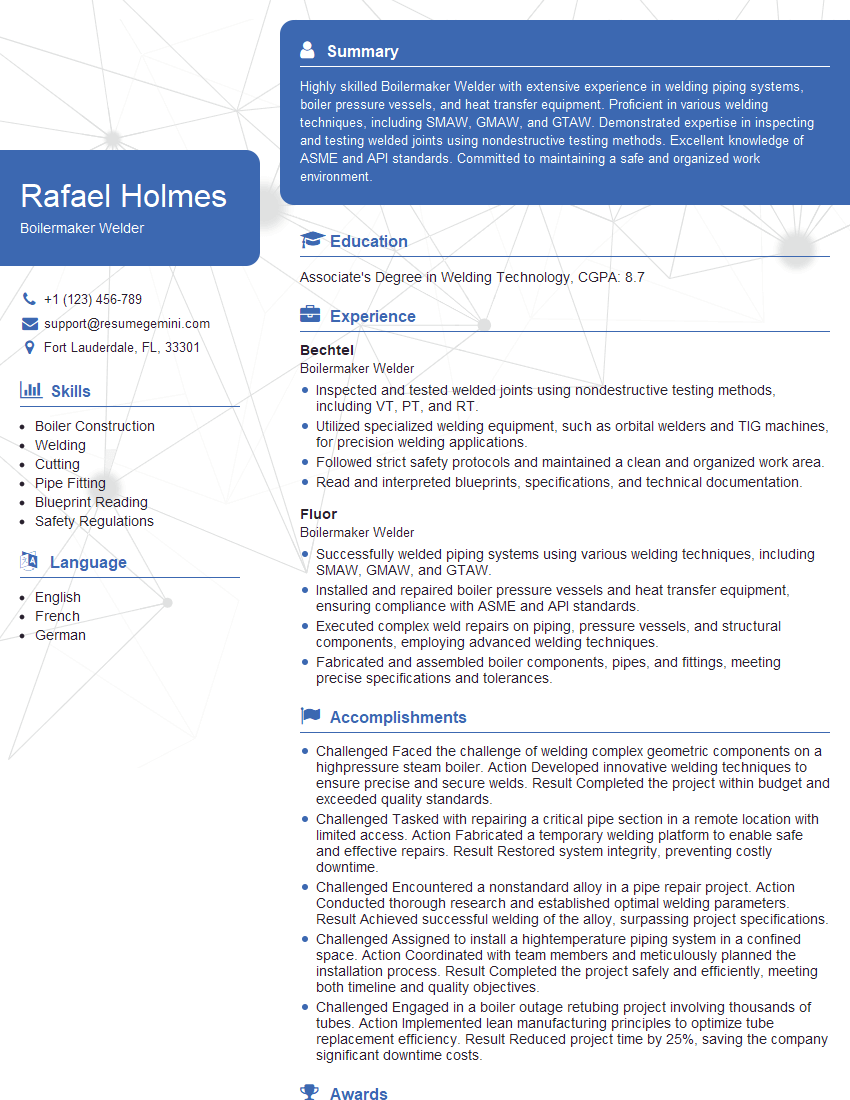

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boilermaker Welder

1. What are the different types of welding processes used in boilermaking?

There are several types of welding processes used in boilermaking, including:

- Shielded Metal Arc Welding (SMAW) or Stick Welding

- Gas Metal Arc Welding (GMAW) or MIG Welding

- Gas Tungsten Arc Welding (GTAW) or TIG Welding

- Submerged Arc Welding (SAW)

- Flux-Cored Arc Welding (FCAW)

2. What are the key factors to consider when selecting the appropriate welding process for a particular application in boilermaking?

Material Thickness:

- SMAW and FCAW are suitable for thicker materials.

- GMAW and GTAW are better for thinner materials.

Joint Design:

- SMAW and FCAW are suitable for various joint designs.

- GMAW and GTAW are better for precise and complex joints.

Weld Quality:

- GTAW provides the highest quality welds.

- GMAW and FCAW offer good weld quality for industrial applications.

- SMAW produces welds with lower strength and ductility compared to other methods.

Cost and Efficiency:

- SMAW and FCAW are typically more cost-effective but less efficient.

- GMAW and GTAW are more efficient but can be more expensive.

3. How do you ensure that your welds meet the required standards and specifications for boilermaking?

To ensure weld quality, I follow these steps:

- Properly preparing joint surfaces by cleaning and beveling.

- Selecting the correct welding process and parameters based on the material and joint design.

- Using high-quality welding consumables and equipment.

- Maintaining proper welding techniques and adhering to welding procedures.

- Conducting visual inspections and non-destructive testing to verify weld quality.

4. What are the common defects that can occur in boilermaking welds, and how do you prevent them?

- Porosity: Caused by gas entrapment during welding. Prevented by using clean materials, proper shielding gas, and avoiding moisture.

- Lack of Fusion: Insufficient melting of base metal. Prevented by proper joint preparation, correct welding parameters, and avoiding excessive travel speed.

- Undercut: Grooving of the base metal adjacent to the weld. Prevented by using appropriate welding techniques, avoiding excessive heat input, and maintaining proper joint geometry.

- Cracking: Rupture of the weld metal. Prevented by selecting proper welding procedures, controlling cooling rates, and avoiding excessive stresses.

5. What are the safety precautions that you take when working as a Boilermaker Welder?

Safety is paramount. I strictly adhere to these precautions:

- Wearing appropriate Personal Protective Equipment (PPE), including welding helmet, gloves, protective clothing, and safety glasses.

- Ensuring proper ventilation to remove welding fumes.

- Inspecting equipment before use and maintaining it regularly.

- Following established safety protocols for handling and storing welding gases.

- Being aware of potential hazards, such as electrical shock, hot surfaces, and confined spaces.

6. How do you stay up-to-date with the latest advancements in boilermaking welding techniques and technologies?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Seeking training and certification from recognized welding organizations.

- Consulting with welding engineers and manufacturers.

7. What is your experience with welding in confined spaces?

I have significant experience welding in confined spaces, such as boilers, tanks, and pressure vessels. I am familiar with the safety precautions and techniques required for working in these environments, including:

- Proper ventilation and monitoring of air quality.

- Using specialized welding equipment designed for confined spaces.

- Maintaining communication with a safety observer outside the confined space.

- Following established procedures for entering, working, and exiting confined spaces.

8. How do you handle working with high-pressure piping systems?

When working with high-pressure piping systems, I prioritize safety by adhering to the following measures:

- Thoroughly inspecting the system for any defects or damage before starting work.

- Following proper isolation and depressurization procedures to ensure the system is safe to work on.

- Using appropriate welding techniques and materials to maintain the integrity of the piping system.

- Conducting pressure testing and inspections to verify the quality of the welds.

9. What is your approach to ensuring the structural integrity of welded components in boilermaking?

- Proper Joint Design: Designing welds to withstand the anticipated loads and stresses.

- Weld Quality: Employing appropriate welding techniques and materials to achieve high-quality welds.

- Non-Destructive Testing: Using methods such as radiography or ultrasonic testing to verify weld integrity.

- Stress Relief: Applying heat treatment to reduce residual stresses in welded components.

- Regular Inspection and Maintenance: Monitoring welded components for any signs of damage or deterioration.

10. Describe a challenging boilermaking welding project you have worked on and how you successfully completed it.

I worked on the fabrication of a high-pressure steam boiler. The project involved welding thick-walled carbon steel plates and tubes under strict quality standards. I used advanced welding techniques, such as submerged arc welding and orbital GTAW, to achieve the required weld quality. I also conducted extensive non-destructive testing to ensure the structural integrity of the boiler components.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boilermaker Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boilermaker Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boilermaker Welder holds a multifaceted role, requiring proficiency in a diverse range of tasks. They are charged with shaping and fitting metal components, performing various kinds of welding operations, and ensuring the integrity of boilers and pressure vessels.

1. General Knowledge

A Boilermaker Welder must possess a comprehensive understanding of boiler and pressure vessel construction, principles of welding, blueprint reading, and safety regulations pertaining to welding operations.

- Interpret blueprints and engineering drawings to determine work specifications.

- Stay abreast of industry standards, codes, and regulations governing welding.

- Maintain a thorough understanding of welding techniques and metallurgy.

- Adhere to strict safety protocols to ensure the protection of themselves and others.

2. Fabrication and Installation

Boilermaker Welders are responsible for fabricating and installing boiler and pressure vessel components.

- Form and fit metal plates, pipes, and other components.

- Perform welding using various techniques such as shielded metal arc welding, gas metal arc welding, and gas tungsten arc welding.

- Ensure the structural integrity and alignment of fabricated components.

3. Inspection and Maintenance

Boilermaker Welders also conduct inspections and maintenance on boilers and pressure vessels to ensure their safe and efficient operation.

- Inspect boilers and pressure vessels for any signs of wear, corrosion, or damage.

- Perform repairs and modifications as necessary to maintain the integrity of the equipment.

- Maintain an accurate record of all inspections and repairs.

4. Safety and Quality Assurance

Ensuring the safety of themselves, colleagues, and the general public is paramount for Boilermaker Welders. Additionally, they are responsible for producing high-quality work that meets industry standards.

- Follow proper safety procedures to prevent accidents and injuries.

- Maintain a clean and organized work area.

- Thoroughly test and inspect all welds to ensure their strength and durability.

Interview Tips

Preparing for a Boilermaker Welder interview requires meticulous preparation and showcasing your skills and experience effectively. Here are some tips to help you ace the interview:

1. Research the Company and Position

Prior to the interview, conduct thorough research on the company and the specific Boilermaker Welder position you are applying for. This demonstrates your interest and enthusiasm for the role.

- Visit the company’s website to learn about their history, products, and services.

- Review the job description carefully to identify the essential responsibilities and qualifications.

- Research industry-specific publications and news to stay abreast of current trends and technologies.

2. Highlight Your Skills and Experience

During the interview, emphasize the skills and experience that are most relevant to the job requirements. Quantify your accomplishments whenever possible using specific metrics and examples.

- Describe your expertise in different welding techniques and your experience working on various types of boilers and pressure vessels.

- Showcase your knowledge of safety regulations and your commitment to maintaining a safe work environment.

- Provide examples of your ability to work independently and as part of a team.

3. Prepare for Common Interview Questions

Anticipating common interview questions and preparing thoughtful responses ahead of time can boost your confidence and performance during the interview.

- Explain your understanding of the role of a Boilermaker Welder and how your skills and experience align with the job requirements.

- Describe a challenging project or situation you encountered and how you overcame it.

- Discuss your safety practices and how you ensure the quality of your work.

4. Ask Informed Questions

Asking insightful questions not only demonstrates your interest in the position but also provides you with valuable information about the company and the role. Prepare a list of questions to ask the interviewer.

- Inquire about the company’s current projects and future growth plans.

- Ask about opportunities for professional development and training.

- Seek clarification on any aspects of the job description or company culture that you are curious about.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally for the interview and arrive on time. This shows respect for the interviewer and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Boilermaker Welder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Boilermaker Welder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.