Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Bolt Labeler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bolt Labeler

1. Describe the process of labeling bolts.

The process of labeling bolts involves several steps:

- Preparation: The bolts are cleaned and prepared to receive the label. This may involve removing any dirt or debris and ensuring the surface is smooth.

- Label Selection: The appropriate label is selected based on the bolt’s size, material, and application. The label may contain information such as the bolt’s grade, size, and manufacturer.

- Label Application: The label is applied to the bolt using a specialized labeling machine. The machine precisely positions the label and applies pressure to ensure it adheres securely.

- Verification: After the label is applied, it is inspected to ensure it is correctly placed, legible, and free of any defects.

2. What types of labeling machines are used for bolts?

Manual Labeling Machines

- Require manual application of labels.

- Suitable for small-scale labeling operations.

Semi-Automatic Labeling Machines

- Combine manual label feeding with automated label application.

- Increase efficiency and accuracy compared to manual machines.

Automatic Labeling Machines

- Fully automated labeling process.

- High speed and precision.

- Integrated with production lines for continuous labeling.

3. What are the key considerations when selecting a labeling machine for bolts?

When selecting a labeling machine for bolts, several key considerations include:

- Bolt Size and Shape: The machine should be compatible with the size and shape of the bolts being labeled.

- Label Type: The machine should be able to handle the type of label being used, such as paper, plastic, or metal.

- Throughput: The machine should meet the required labeling speed and capacity.

- Accuracy and Precision: The machine should ensure accurate and precise label placement.

- Durability and Maintenance: The machine should be durable and easy to maintain.

4. What quality control measures are implemented to ensure accurate and consistent bolt labeling?

Quality control measures for accurate and consistent bolt labeling include:

- Label Verification: Checking the labels for accuracy, legibility, and completeness before application.

- Machine Calibration: Regular calibration of labeling machines to ensure precise label placement.

- Visual Inspection: Random sampling of labeled bolts to visually inspect for any defects or errors.

- Traceability: Maintaining records of labeling processes, including label specifications, machine settings, and inspection results.

5. What are the potential challenges associated with bolt labeling and how can they be mitigated?

Potential challenges with bolt labeling and their mitigation strategies include:

- Irregular Bolt Surfaces: Bolts may have uneven or curved surfaces, making label adhesion difficult. Mitigation: Using specialized labels designed for irregular surfaces or applying a primer to improve adhesion.

- Label Damage: Labels may be damaged during handling or transportation. Mitigation: Using durable labels and implementing proper handling procedures to prevent damage.

- Label Fading: Labels may fade or discolor over time due to exposure to sunlight or harsh environments. Mitigation: Using UV-resistant labels or applying a clear protective coating.

6. Describe the importance of adhesive selection for bolt labeling.

Adhesive selection is crucial for bolt labeling as it ensures the label remains securely attached to the bolt even under demanding conditions. Factors to consider include:

- Bolt Material: Different adhesives are suitable for different bolt materials, such as steel, aluminum, or stainless steel.

- Label Material: The adhesive should be compatible with the label material used, such as paper, plastic, or metal.

- Environment: The adhesive should withstand the environmental conditions the labeled bolts will be exposed to, such as temperature, humidity, and chemicals.

7. What are the different techniques used to ensure proper alignment of labels on bolts?

To ensure proper alignment of labels on bolts, various techniques are employed:

- Precision Labeling Machines: These machines use advanced sensors and control systems to accurately position labels on bolts.

- Registration Marks: Reference marks printed on the bolts or labels guide the labeling machine for precise placement.

- Optical Inspection: Cameras or vision systems verify the label alignment before and/or after application.

8. How do you ensure the legibility and durability of labels on bolts?

Legibility

- Choosing high-contrast color combinations.

- Using clear and concise fonts.

- Optimizing label size and placement for visibility.

Durability

- Selecting durable label materials resistant to abrasion, moisture, and chemicals.

- Applying protective coatings or laminates to enhance label longevity.

- Following proper labeling procedures and using compatible adhesives.

9. Describe the maintenance and troubleshooting procedures for bolt labeling machines.

Maintenance

- Regular cleaning and lubrication.

- Periodic calibration and adjustment.

- Replacement of worn parts and components.

Troubleshooting

- Identifying common problems, such as label misalignment, label damage, or machine malfunctions.

- Implementing corrective actions based on the identified issue.

- Consulting with the machine manufacturer or technical experts when necessary.

10. How do you stay updated with the latest advancements and best practices in bolt labeling technology?

I stay updated with the latest advancements and best practices in bolt labeling technology through the following methods:

- Industry Publications and Journals: Reading trade publications and industry journals to keep abreast of technological developments.

- Conferences and Exhibitions: Attending industry conferences and exhibitions to learn about new products and innovations.

- Training and Workshops: Participating in training programs and workshops offered by manufacturers and industry experts.

- Online Resources: Exploring online forums, websites, and social media platforms to connect with other professionals and stay informed.

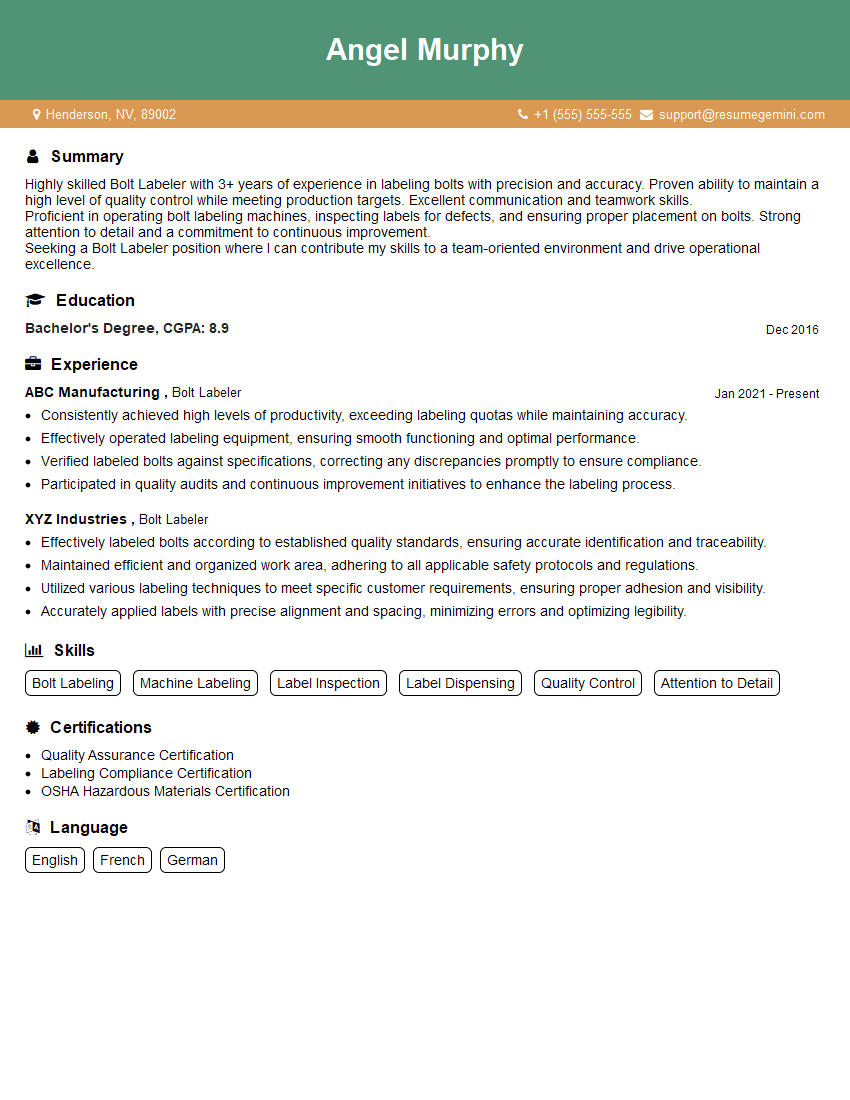

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bolt Labeler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bolt Labeler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Bolt Labeler is accountable for applying labels to bolts in accordance with established procedures and specifications. This role plays a vital role in ensuring the accurate labeling of bolts, contributing to efficient production and inventory management processes.

1. Labeling Operations

Applies labels to bolts according to specified requirements, ensuring accuracy and legibility

- Verifies labels for correctness before application

- Uses appropriate labeling machines or tools

2. Quality Control

Inspects bolts for proper labeling, identifying and correcting errors

- Adheres to established quality standards

- Maintains accurate records of labeling operations

3. Inventory Management

Monitors inventory levels of labels and bolts

- Reports discrepancies or shortages promptly

- Assists in maintaining proper storage conditions

4. Machine Maintenance

Performs basic maintenance on labeling machines

- Cleans and lubricates equipment

- Reports any malfunctions or repairs needed

Interview Tips

Interview preparation is crucial for a successful job interview. Here are some tips and hacks to help candidates ace the interview for the Bolt Labeler position:

1. Research the Company and the Role

Thoroughly research the company’s background, industry, and values. Also, delve into understanding the specific requirements and responsibilities of the Bolt Labeler position

- Practice answering common interview questions related to your experience, skills, and qualifications.

- Prepare thoughtful questions to ask the interviewer, demonstrating your interest and engagement.

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to emphasize your relevant experience and skills that align with the job responsibilities.

- Quantify your accomplishments and provide specific examples of your contributions

- Demonstrate your attention to detail, accuracy, and ability to work independently.

3. Show Enthusiasm and Motivation

Convey your enthusiasm and motivation for the Bolt Labeler position during the interview.

- Express your interest in the company and how your skills can contribute to their success.

- Be prepared to discuss your career goals and how this role aligns with them.

4. Prepare for Behavioral Questions

Behavioral interview questions are commonly asked to assess your problem-solving skills and how you handle specific situations.

- Use the STAR method to answer these questions: Situation, Task, Action, Result.

- Describe specific examples where you demonstrated strong attention to detail, accuracy, and efficiency.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Bolt Labeler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Bolt Labeler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.