Are you gearing up for a career in Bolt Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bolt Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

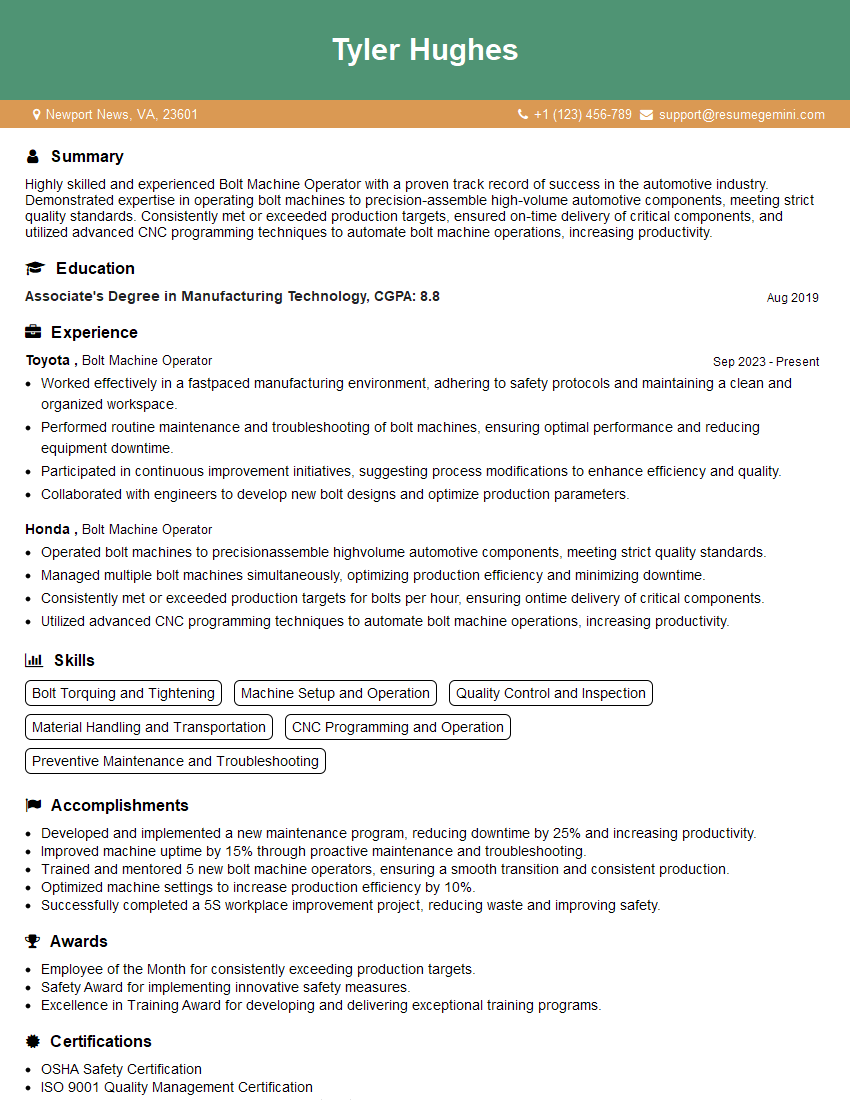

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bolt Machine Operator

1. How do you ensure that the bolts you produce meet the required specifications?

To ensure the bolts meet specifications, I follow a meticulous quality control process that involves several key steps:

- Dimensional Inspection: I use precision measuring tools, such as calipers and micrometers, to verify that the bolts’ dimensions, including length, diameter, and head size, conform to the specified tolerances.

- Surface Inspection: I inspect the bolts’ surface for any defects, such as scratches, cracks, or burrs, that may affect their performance or aesthetics.

- Strength Testing: I conduct tensile and shear strength tests to ensure that the bolts meet the required strength requirements for the intended application.

- Hardness Testing: I use a Rockwell hardness tester to determine the material’s hardness and ensure it meets the specified hardness range.

- Record Keeping: I maintain detailed records of all inspection and testing results, which can be used for traceability and quality assurance purposes.

2. Can you explain the process of heat treating bolts?

1: Types of Heat Treatment

- Annealing: This process involves heating the bolts to a high temperature and then slowly cooling them to soften the material and improve toughness.

- Hardening: The bolts are heated to a high temperature and then rapidly cooled to increase their hardness and strength.

- Tempering: This process involves heating the bolts to a lower temperature after hardening to reduce brittleness and improve toughness.

Subheading 2: Benefits of Heat Treatment

- Enhanced mechanical properties, such as strength, hardness, and toughness

- Improved surface characteristics, such as wear resistance and corrosion resistance

- Stress relief to minimize the risk of cracking and deformation during machining or assembly

3. What types of machines do you use to produce bolts?

- Bolt Making Machine: This automated machine forms bolts from wire or bar stock by cold heading or thread rolling.

- Bolt Trimming Machine: Used to trim excess material from the bolt heads and threads to achieve the desired dimensions.

- Thread Rolling Machine: Creates threads on the bolts by rolling them between hardened dies.

- Heat Treatment Furnace: Used for annealing, hardening, and tempering the bolts to modify their mechanical properties.

- Inspection and Testing Equipment: Various tools and machines, such as calipers, micrometers, tensile testers, and hardness testers, are used to verify the bolts’ dimensions, strength, and quality.

4. What are the common materials used in bolt manufacturing?

- Steel Alloys: Carbon steel, stainless steel, alloy steel, providing varying combinations of strength, corrosion resistance, and machinability.

- Non-Ferrous Metals: Aluminum, brass, and titanium, offering lightweight, corrosion-resistant, and non-magnetic properties.

- Speciality Materials: Inconel, Monel, and Hastelloy, used in extreme environments or for specific applications requiring high strength, corrosion resistance, or temperature resistance.

5. Can you describe the different types of bolt head styles?

- Hex Head: The most common type, characterized by a hexagonal-shaped head that provides good grip for tightening and loosening.

- Socket Head: Has a recessed hex drive that allows for tightening with a hex key or Allen wrench, providing a flush surface.

- Button Head: Features a rounded head with a low profile, often used in confined spaces or for aesthetic purposes.

- Pan Head: Similar to a button head but with a slightly larger and flatter head, offering a balance between strength and low profile.

- Carriage Bolt: Has a domed or oval head with a square neck, designed for use with wood and is often used in construction.

6. How do you troubleshoot common bolt machine problems?

- Poor Thread Quality: Check for worn dies, improper setup, or material defects.

- Oversized or Undersized Bolts: Adjust machine settings, check for worn tools, or ensure the correct raw material is being used.

- Cracked or Deformed Bolts: Inspect for excessive force, improper heat treatment, or material defects.

- Bolt Jams: Clear any obstructions, check for misalignment or worn components, and ensure proper lubrication.

- Machine Overheating: Check for proper ventilation, lubrication, and excessive load on the machine.

7. How do you maintain the accuracy and efficiency of bolt machines?

- Regular Maintenance: Follow manufacturer’s guidelines for lubrication, cleaning, and component replacement.

- Calibration and Inspection: Regularly calibrate measuring tools and inspect machine components for wear and damage.

- Tooling Management: Keep cutting dies and forming tools sharp and in good condition to ensure precision and efficiency.

- Process Optimization: Monitor production data, analyze bottlenecks, and make adjustments to improve efficiency and reduce scrap.

- Training and Certification: Ensure operators are trained and certified to operate the machines safely and effectively.

8. How do you ensure safety when operating bolt machines?

- Wear Proper PPE: Safety glasses, gloves, and earplugs to protect against hazards.

- Machine Guarding: Ensure all moving parts are properly guarded to prevent contact.

- Lockout/Tagout Procedures: Follow established procedures for isolating and de-energizing machines before performing maintenance.

- Tool Inspection: Check tools for damage or wear before use to prevent accidents.

- Emergency Stop Training: Train operators on the location and proper use of emergency stop buttons.

9. Can you explain the different types of coatings used on bolts?

- Zinc Plating: Provides corrosion protection and is commonly used for outdoor applications.

- Cadmium Plating: Offers excellent corrosion resistance and is often used in marine environments.

- Nickel Plating: Enhances corrosion resistance and provides a decorative finish.

- Black Oxide Coating: Improves corrosion resistance and reduces glare.

- Powder Coating: Provides a durable and protective finish with various color options.

10. What is your experience with working in a fast-paced manufacturing environment?

In my previous role at [Company Name], I worked in a demanding production environment where efficiency and accuracy were paramount. I was responsible for operating several bolt machines simultaneously, ensuring that production targets were met while maintaining high quality standards. I am accustomed to working under pressure, managing multiple tasks, and adapting quickly to changing production demands.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bolt Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bolt Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bolt Machine Operators are responsible for the safe and efficient operation of bolt manufacturing machines. Their primary duties include:

1. Machine Operation

Monitoring and controlling bolt manufacturing machines to ensure optimal production rates and product quality.

- Setting up and adjusting machines for different bolt sizes and materials.

- Inspecting raw materials (e.g., wire coils) and finished products (e.g., headed bolts) to ensure they meet specifications.

2. Maintenance and Troubleshooting

Performing routine maintenance checks and troubleshooting to prevent equipment breakdowns and ensure smooth operations.

- Cleaning and lubricating machines regularly.

- Identifying and resolving mechanical issues by analyzing error codes and taking corrective actions.

3. Quality Control

Ensuring that manufactured bolts meet quality standards through regular inspections and testing.

- Conducting dimensional, strength, and metallurgical tests to verify bolt properties.

- Maintaining accurate records of inspections and test results.

4. Safety and Compliance

Adhering to all safety regulations and procedures to minimize risks and maintain a safe work environment.

- Wearing appropriate personal protective equipment (e.g., gloves, goggles).

- Following established lock-out/tag-out procedures to prevent accidents.

Interview Tips

To ace the interview for a Bolt Machine Operator position, follow these preparation tips:

1. Research the Company and Industry

Demonstrate your interest in the company and its products by learning about their history, operations, and industry trends.

- Visit the company website, read industry publications, etc.

- Identify the specific products manufactured in the department where you’re applying.

2. Emphasize Relevant Skills and Experience

Highlight your technical skills in bolt manufacturing, including machine operation, maintenance, and quality control.

- Quantify your achievements whenever possible (e.g., “Increased production efficiency by 15%”).

- Explain how your previous experience aligns with the job responsibilities.

3. Prepare for Technical Questions

Expect questions related to bolt manufacturing processes, machine operation, and troubleshooting techniques.

- Review basic bolt metallurgy and quality standards.

- Practice troubleshooting common machine issues.

4. Show Your Safety Consciousness

Emphasize your commitment to safety and compliance in the workplace.

- Describe your experience with safety protocols and risk assessment.

- Explain how you prioritize safety in your daily work routine.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Bolt Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.