Are you gearing up for a career in Bolt Sorter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bolt Sorter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

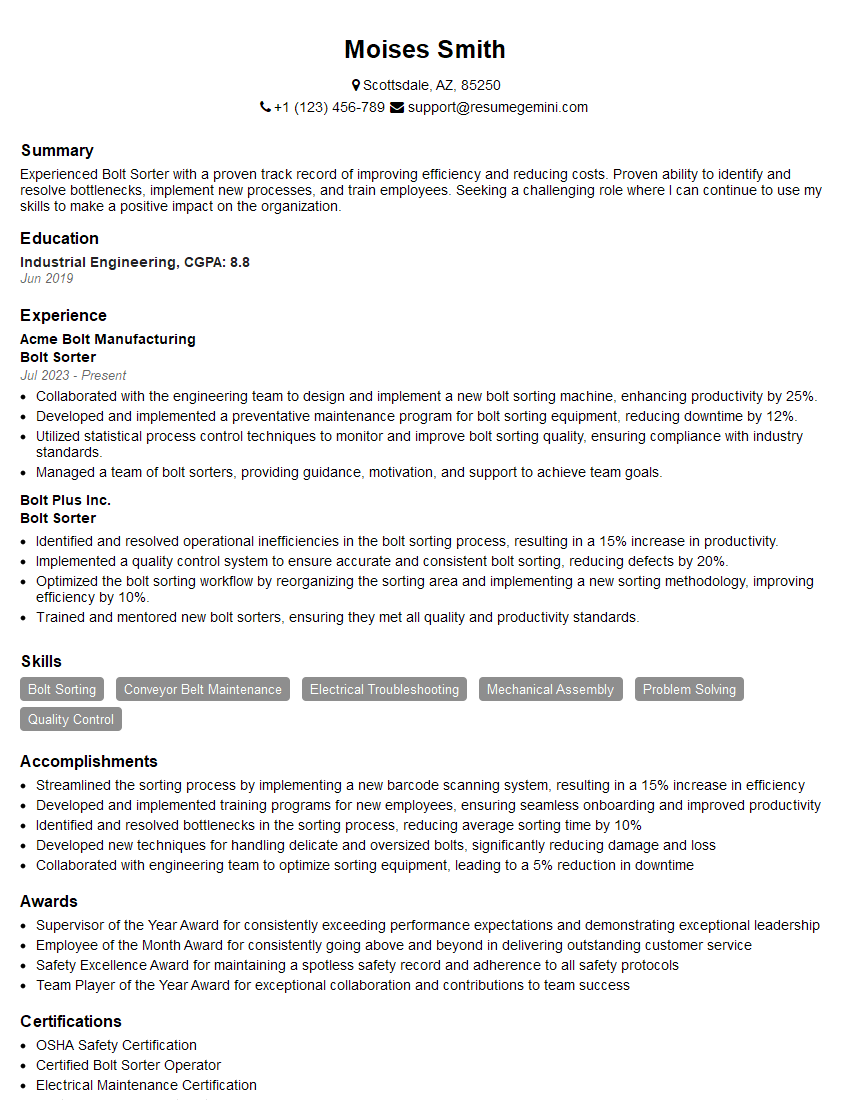

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bolt Sorter

1. Describe the process of sorting bolts using a Bolt Sorter?

The process of sorting bolts using a Bolt Sorter typically involves the following steps:

- Loading the bolts: The bolts are loaded into the Bolt Sorter’s hopper or feeding mechanism.

- Feeding the bolts: The bolts are fed into the sorting mechanism, which may involve a conveyor belt, vibratory feeder, or other means of moving the bolts.

- Sorting the bolts: The sorting mechanism uses various methods to sort the bolts based on pre-defined criteria, such as length, diameter, or thread type.

- Collecting the sorted bolts: The sorted bolts are collected into separate bins or containers based on their sorted categories.

- Monitoring and control: The Bolt Sorter is typically equipped with sensors and controls to monitor the sorting process and ensure accurate and efficient sorting.

2. What are the different types of Bolt Sorters available?

Mechanical Bolt Sorters

- Use mechanical components such as gears, cams, and levers to sort bolts.

- Typically designed for high-volume sorting applications.

Optical Bolt Sorters

- Use optical sensors to measure bolt dimensions and features.

- Can sort bolts based on precise criteria, such as thread pitch and head shape.

Combination Bolt Sorters

- Combine both mechanical and optical sorting techniques.

- Offer high accuracy and versatility in bolt sorting.

3. What are the key factors to consider when selecting a Bolt Sorter?

When selecting a Bolt Sorter, it is important to consider the following factors:

- Sorting requirements: The type of bolts, sorting criteria, and desired accuracy.

- Capacity and throughput: The required sorting speed and volume.

- Integration with existing systems: Compatibility with other equipment and automation systems.

- Reliability and maintenance: The durability and ease of maintenance of the Bolt Sorter.

- Cost and budget: The capital investment and ongoing operating costs.

4. What are the benefits of using a Bolt Sorter?

Using a Bolt Sorter offers several benefits, including:

- Increased productivity: Automation of the sorting process saves time and labor costs.

- Improved accuracy: Automated sorting reduces the risk of human error and ensures consistent quality.

- Reduced waste: Accurate sorting prevents mis-sorted bolts from entering the manufacturing process, reducing scrap and rework.

- Enhanced safety: Automated sorting eliminates the need for manual handling of bolts, improving workplace safety.

- Data collection: Some Bolt Sorters provide data on sorting performance, which can be used for process optimization.

5. What are the common troubleshooting steps for Bolt Sorters?

When troubleshooting Bolt Sorters, common steps include:

- Checking power and connections: Ensuring that the Bolt Sorter is properly connected and receiving power.

- Inspecting sensors: Verifying that sensors are clean, aligned, and functioning correctly.

- Calibrating the system: Ensuring that the Bolt Sorter is calibrated according to the required sorting criteria.

- Cleaning and maintenance: Removing any debris or blockages that may affect sorting.

- Consulting the manufacturer’s manual: Referencing the manufacturer’s documentation for specific troubleshooting instructions.

6. How do you ensure the accuracy and reliability of Bolt Sorters?

To ensure accuracy and reliability of Bolt Sorters, the following practices are important:

- Regular calibration: Periodically calibrating the Bolt Sorter to maintain precision in sorting.

- Preventive maintenance: Performing regular inspections, cleaning, and lubrication to prevent breakdowns.

- Quality control: Implementing quality control measures to verify the accuracy of the sorting process.

- Operator training: Ensuring that operators are properly trained on the operation and maintenance of the Bolt Sorter.

- Using reliable components: Selecting high-quality components and sensors for the Bolt Sorter.

7. Describe the safety precautions that should be taken when operating a Bolt Sorter?

When operating a Bolt Sorter, the following safety precautions should be observed:

- Wearing appropriate PPE: Operators should wear protective gear such as gloves, safety glasses, and earplugs.

- Guarding moving parts: Ensuring that all moving parts of the Bolt Sorter are properly guarded to prevent contact.

- Avoiding loose clothing: Loose clothing can get caught in the machinery, so operators should wear fitted clothing.

- Following lockout/tagout procedures: When performing maintenance or repairs, proper lockout/tagout procedures should be followed to prevent accidental startup.

- Regular safety inspections: Conducting regular safety inspections to identify and address any potential hazards.

8. What are the latest advancements in Bolt Sorter technology?

Recent advancements in Bolt Sorter technology include:

- High-speed sorting: Bolt Sorters with faster sorting speeds to meet increasing production demands.

- Improved sensor technology: Advanced sensors for more precise sorting based on various parameters.

- Integration with automation systems: Bolt Sorters that can seamlessly integrate with other automated systems for increased efficiency.

- Remote monitoring and control: Ability to monitor and control Bolt Sorters remotely for improved productivity and maintenance.

- Artificial intelligence (AI): AI-powered Bolt Sorters for optimized sorting performance and predictive maintenance.

9. How do you handle situations where the Bolt Sorter malfunctions or encounters unexpected errors?

In case of malfunctions or errors, the following steps should be taken:

- Identifying the issue: Observe the Bolt Sorter’s behavior and error messages to identify the source of the problem.

- Consulting the user manual: Refer to the manufacturer’s user manual for troubleshooting instructions.

- Performing basic troubleshooting: Check power connections, sensors, and other easily accessible components.

- Contacting technical support: If the issue cannot be resolved through basic troubleshooting, contact the manufacturer’s technical support for assistance.

- Documenting the incident: Keep records of all malfunctions and troubleshooting steps taken for future reference.

10. How do you stay updated with the latest advancements and best practices in Bolt Sorter technology?

To stay updated with advancements and best practices, the following strategies are employed:

- **Attending industry conferences and exhibitions:

- **Reading technical publications and journals:

- **Participating in online forums and discussions:

- **Consulting with manufacturers and experts:

- **Conducting research and development:

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bolt Sorter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bolt Sorter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bolt Sorters play a crucial role in the manufacturing and distribution sectors, ensuring the efficient and accurate movement of products. Their responsibilities encompass a range of tasks that contribute to the smooth operation of production and distribution lines.

1. Bolt Sorting

The primary responsibility of a Bolt Sorter is to sort bolts based on specific criteria, such as size, thread count, and material. They use various sorting machines and techniques to segregate bolts efficiently, ensuring that the right bolts are used for specific applications.

- Operate sorting machines to separate bolts based on size, thread count, and material.

- Manually inspect bolts for defects and ensure they meet quality standards.

2. Inventory Management

Bolt Sorters are responsible for maintaining inventory levels of bolts, ensuring that there is adequate stock to meet production or distribution needs. They monitor inventory levels, place orders for new bolts, and track the movement of bolts throughout the warehouse or manufacturing facility.

- Monitor inventory levels and place orders for new bolts as needed.

- Track the movement of bolts to ensure timely delivery to production or distribution lines.

3. Equipment Maintenance

Bolt Sorters are also responsible for maintaining the equipment they use, including sorting machines and other tools. They perform regular inspections, clean and lubricate equipment, and troubleshoot and repair minor issues to ensure that sorting operations run smoothly.

- Perform regular inspections of sorting machines and other equipment.

- Clean and lubricate equipment to prevent breakdowns.

- Troubleshoot and repair minor issues to keep equipment operational.

4. Safety Compliance

Bolt Sorters must adhere to safety regulations and protocols to ensure their safety and the safety of others in the workplace. They follow established procedures, wear appropriate safety gear, and report any unsafe conditions or practices to their supervisors.

- Follow established safety regulations and protocols.

- Wear appropriate safety gear, such as gloves and safety glasses.

- Report any unsafe conditions or practices to supervisors.

Interview Tips

Preparing for an interview for a Bolt Sorter position requires a combination of technical knowledge, understanding of the industry, and strong communication skills. Here are some tips to help candidates ace their interview.

1. Research the Company and Industry

Research the company you are interviewing with and the industry in which they operate. This will give you a good understanding of the company’s products or services, their market position, and the challenges and opportunities in the industry.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Talk to people who work in the industry.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the job of Bolt Sorter. This includes your ability to sort bolts efficiently and accurately, your knowledge of inventory management, and your experience with equipment maintenance. You should also emphasize your safety awareness and commitment to following safety protocols.

- Describe your experience in sorting bolts, including the types of bolts and sorting techniques you have used.

- Discuss your knowledge of inventory management, including how you have tracked and maintained inventory levels.

- Explain your experience with equipment maintenance, including the types of equipment you have maintained and the repairs you have performed.

3. Be Prepared to Answer Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” Be prepared to answer these questions in a clear and concise manner, and be sure to tailor your answers to the specific job you are interviewing for.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

4. Ask Questions

At the end of the interview, be sure to ask questions of your own. This shows that you are interested in the position and the company, and it gives you an opportunity to learn more about the company and the job.

- What is the most challenging aspect of the job?

- What are the company’s goals for the future?

- What opportunities are there for advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bolt Sorter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!