Are you gearing up for an interview for a Bondactor Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Bondactor Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

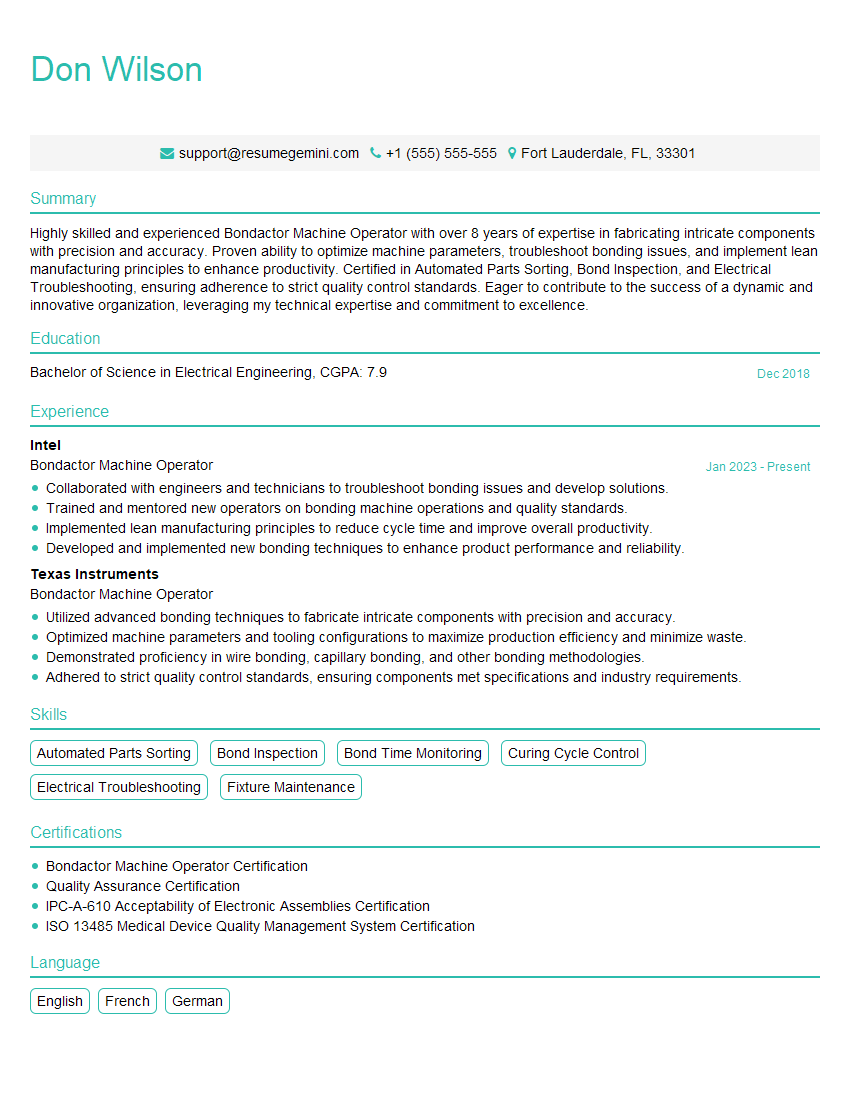

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bondactor Machine Operator

1. Can you describe the process of bonding dissimilar materials using a Bondactor machine?

Sure, the process of bonding dissimilar materials using a Bondactor machine involves several steps:

- Surface preparation: The surfaces to be bonded are cleaned and prepared to ensure a strong bond.

- Adhesive application: An adhesive is applied to one or both of the surfaces to be bonded.

- Positioning: The surfaces are carefully positioned and aligned before bonding.

- Bonding: The Bondactor machine applies pressure and heat to the surfaces, creating a permanent bond.

- Cooling: The bonded materials are allowed to cool and cure.

- Inspection: The bond is inspected to ensure it meets the required specifications.

2. What are the different types of adhesives used in Bondactor machines?

Thermoplastic Adhesives

- Melt and flow under heat, forming a bond upon cooling.

- Examples include hot melt adhesives, pressure-sensitive adhesives.

Thermosetting Adhesives

- Cure and harden under heat or exposure to a catalyst.

- Examples include epoxy adhesives, acrylic adhesives.

Hybrid Adhesives

- Combine properties of thermoplastic and thermosetting adhesives.

- Offer both flexibility and strength.

3. How do you determine the optimal bonding parameters (pressure, temperature, and time) for a specific application?

Determining the optimal bonding parameters is crucial for achieving a strong and durable bond. I typically follow these steps:

- Review manufacturer’s recommendations: Start with the recommended parameters provided by the adhesive manufacturer.

- Conduct small-scale tests: Perform tests with varying parameters to determine the optimal settings for the specific materials and application.

- Consider material properties: Take into account the thermal properties, strength, and surface characteristics of the materials being bonded.

- Monitor bond quality: Use destructive or non-destructive testing methods to evaluate the bond strength and quality.

4. What are some common defects that can occur during the bonding process, and how do you troubleshoot them?

- Weak bond: Caused by insufficient pressure, temperature, or cure time. Adjust parameters and check adhesive compatibility.

- Voids or bubbles: Entrapped air or moisture. Optimize vacuum degassing and improve surface preparation.

- Cracking: Thermal stress or excessive pressure. Adjust bonding parameters and consider using flexible adhesives.

- Delamination: Poor surface preparation or adhesive failure. Ensure proper cleaning and use adhesives suitable for the materials.

5. How do you maintain and calibrate a Bondactor machine?

Regular maintenance and calibration are essential for optimal machine performance and bond quality:

- Daily checks: Inspect for leaks, cleanliness, and proper functioning of components.

- Regular cleaning: Remove adhesive residues, dust, and debris.

- Calibration: Use certified gauges and follow manufacturer’s guidelines to ensure accurate pressure and temperature readings.

- Preventive maintenance: Schedule routine maintenance to replace worn parts and prevent breakdowns.

6. Can you explain how to use a Bondactor machine to bond metal to plastic?

- Surface preparation: Clean and prepare both the metal and plastic surfaces.

- Adhesive selection: Choose an adhesive compatible with both materials and the desired bond strength.

- Bonding parameters: Determine the optimal pressure, temperature, and time based on the adhesive and materials.

- Machine setup: Configure the Bondactor machine according to the bonding parameters.

- Bonding process: Position the metal and plastic components in the machine and initiate the bonding cycle.

- Inspection: Visually inspect the bond for proper alignment and adhesion.

7. What are the safety precautions you observe when operating a Bondactor machine?

Safety is paramount when operating a Bondactor machine:

- Wear appropriate PPE: Safety glasses, gloves, and protective clothing.

- Ensure proper grounding: Prevent electrical hazards.

- Avoid contact with hot surfaces: Wear heat-resistant gloves and avoid touching the machine’s heating elements.

- Be aware of moving parts: Keep hands and other objects away from moving components.

- Follow manufacturer’s instructions: Adhere to recommended operating procedures and safety guidelines.

8. How do you handle deviations from the standard bonding process?

Deviations from the standard process require careful attention:

- Identify the deviation: Determine the cause of the deviation and assess its potential impact.

- Adjust parameters: If necessary, adjust the bonding parameters to accommodate the deviation.

- Document the deviation: Record the deviation and any corrective actions taken.

- Monitor bond quality: Conduct additional testing or inspection to ensure the bond meets specifications.

- Consult with supervisor or technical support: Seek assistance if the deviation is significant or cannot be resolved.

9. What is your experience with using statistical process control (SPC) in Bondactor operations?

SPC is a valuable tool for maintaining consistent bond quality:

- Data collection: Collect bonding data, such as bond strength, cycle time, and temperature.

- Process analysis: Use statistical methods to analyze data and identify trends or deviations.

- Corrective actions: Implement corrective actions based on the analysis to improve process stability.

- Continuous improvement: Regularly review SPC data and make adjustments to optimize the bonding process.

10. How do you stay updated with the latest advancements in Bondactor technology?

- Attend industry conferences and webinars: Stay informed about new technologies and best practices.

- Read technical journals and articles: Expand knowledge and gain insights into advancements.

- Consult with equipment manufacturers: Seek information on the latest machine features and capabilities.

- Network with other professionals: Share knowledge and learn from others in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bondactor Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bondactor Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bondactor Machine Operators play a pivotal role in the manufacturing process, operating specialized machines to bond various materials such as fabrics, paper, and plastics, to create a wide range of products.

1. Machine Setup and Operation

Setting up and operating bondactor machines is a key responsibility, ensuring optimal performance and adherence to safety guidelines.

- Configure and calibrate machines to meet job specifications, adjusting settings such as temperature, pressure, and feed rate.

- Load materials into the machine and ensure proper alignment for bonding.

- Operate the machine according to established procedures to achieve desired bond strength and quality.

2. Quality Control and Inspection

Maintaining quality standards is crucial, and Bondactor Machine Operators are responsible for inspecting products to ensure they meet specifications.

- Conduct regular quality checks on bonded products to verify bond strength and appearance.

- Identify defects and take corrective actions to prevent errors in subsequent production.

- Document inspection findings to maintain accurate quality records.

3. Material Handling

Effectively handling materials is essential for efficient operation.

- Unload bonded products from the machine and transfer them to designated areas for further processing.

- Handle and store materials safely, adhering to established procedures and workplace safety protocols.

- Monitor inventory levels and request materials when necessary to ensure uninterrupted production.

4. Troubleshooting and Maintenance

Troubleshooting and maintaining equipment is important for minimizing downtime and maximizing productivity.

- Identify and address minor machine malfunctions, performing routine maintenance and adjustments.

- Report significant issues or repairs to supervisors or maintenance personnel for prompt resolution.

- Participate in regular preventive maintenance schedules to ensure equipment longevity and reliability.

Interview Tips

Preparing for an interview for a Bondactor Machine Operator position requires careful preparation and attention to key details.

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for to demonstrate your interest and understanding.

- Visit the company’s website and social media pages to learn about their culture, values, and recent developments.

- Review the job description closely to identify the essential responsibilities and qualifications.

- Consider the company’s industry and market position to gain insights into their business goals and challenges.

2. Practice Your Answers

Preparing thoughtful and concise answers to common interview questions will enhance your confidence and convey your preparedness.

- Craft responses that highlight your relevant skills, experience, and accomplishments.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers, providing specific examples that demonstrate your capabilities.

- Anticipate potential technical questions related to bondactor machine operation and troubleshooting, and prepare responses that showcase your knowledge.

3. Highlight Transferable Skills

Even if you do not have direct experience as a Bondactor Machine Operator, emphasize transferable skills that are valuable in the role.

- Demonstrate your proficiency in operating machinery, handling materials, and maintaining equipment.

- Highlight your attention to detail, quality assurance mindset, and problem-solving abilities.

- Emphasize your commitment to safety and your willingness to work in a fast-paced manufacturing environment.

4. Prepare Questions for the Interviewer

Asking thoughtful questions during the interview shows your engagement and interest in the position.

- Inquire about the company’s growth plans and future goals.

- Ask about opportunities for professional development and training.

- Request details about the team you would be working with and the company culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bondactor Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.