Are you gearing up for a career in Bonderizer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Bonderizer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

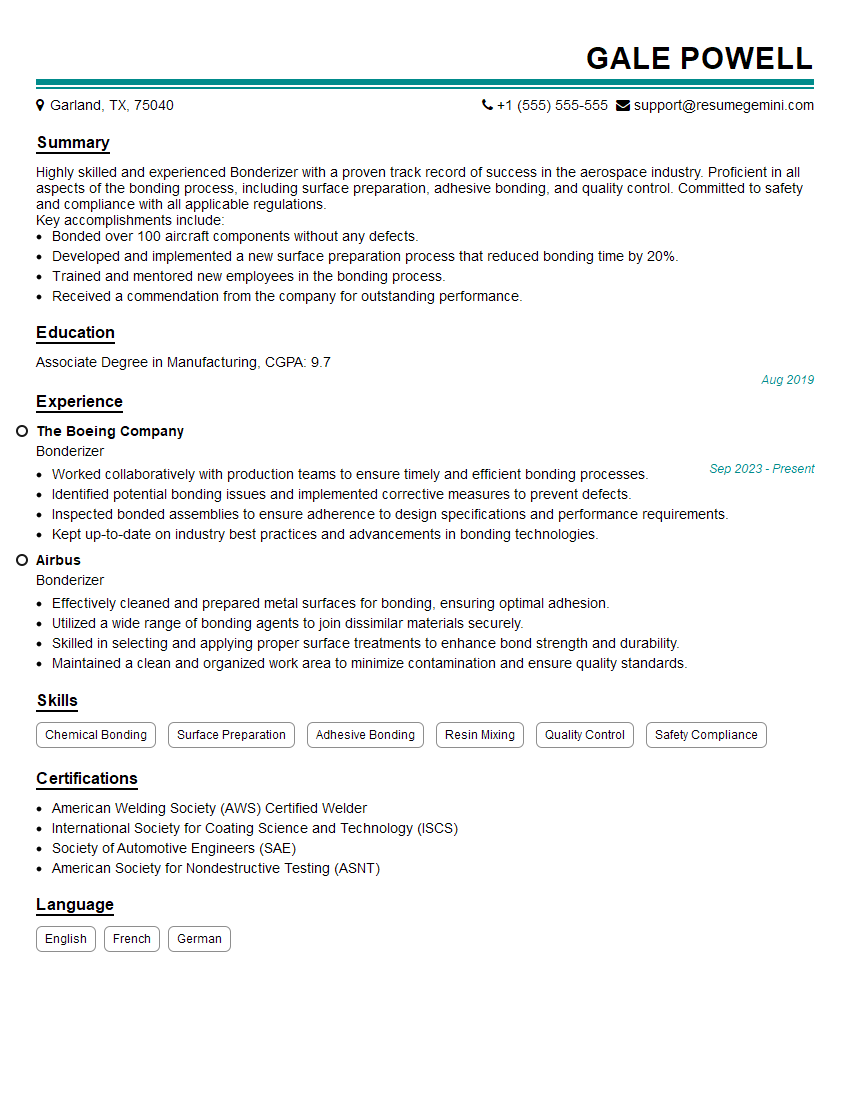

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bonderizer

1. What is the difference between pre-treatment and post-treatment in the bonding process?

- Pre-treatment is the process of preparing the surface of a metal before bonding. It removes contaminants and oxides, and creates a surface that is receptive to the adhesive.

- Post-treatment is the process of protecting the bonded joint from environmental factors such as moisture, heat, and UV radiation.

2. What are the different types of bonding agents used in the bonding process?

- Epoxy adhesives are two-part adhesives that are strong and durable. They are often used for bonding metals, plastics, and composites.

- Acrylic adhesives are one-part adhesives that are easy to apply and cure quickly. They are often used for bonding paper, cardboard, and other lightweight materials.

- Cyanoacrylate adhesives are one-part adhesives that cure very quickly. They are often used for bonding small parts or for quick repairs.

3. What are the factors that affect the strength of a bonded joint?

- Surface preparation: The surface of the materials being bonded must be clean and free of contaminants.

- Bonding agent: The type of bonding agent used will affect the strength of the joint.

- Bonding process: The bonding process must be followed carefully to ensure a strong joint.

- Environmental factors: The bonded joint must be protected from environmental factors such as moisture, heat, and UV radiation.

4. What are the common defects that can occur in bonded joints?

- Voids: Voids are empty spaces in the bonded joint that can weaken the joint.

- Cracks: Cracks are breaks in the bonded joint that can weaken the joint.

- Delamination: Delamination is the separation of the bonded joint between the two materials.

- Corrosion: Corrosion is the degradation of the bonded joint due to environmental factors.

5. How can you prevent defects from occurring in bonded joints?

- Proper surface preparation: The surface of the materials being bonded must be clean and free of contaminants.

- Proper bonding agent selection: The type of bonding agent used must be compatible with the materials being bonded.

- Proper bonding process: The bonding process must be followed carefully to ensure a strong joint.

- Protection from environmental factors: The bonded joint must be protected from environmental factors such as moisture, heat, and UV radiation.

6. What are the advantages of bonding over other joining methods?

- Strength: Bonded joints can be stronger than welded or riveted joints.

- Durability: Bonded joints are resistant to corrosion and other environmental factors.

- Versatility: Bonding can be used to join a wide variety of materials.

- Cost-effectiveness: Bonding is often a more cost-effective joining method than welding or riveting.

7. What are the disadvantages of bonding over other joining methods?

- Curing time: Bonding agents require time to cure, which can slow down the production process.

- Surface preparation: The surface of the materials being bonded must be clean and free of contaminants, which can add to the cost and time of the process.

- Bond strength: The strength of a bonded joint is not always as strong as a welded or riveted joint.

8. What are the different types of bonders used in the bonding process?

- Manual bonders: Manual bonders are used to apply bonding agents to the surface of the materials being bonded.

- Automated bonders: Automated bonders are used to apply bonding agents to the surface of the materials being bonded in a more efficient and consistent manner.

- Dispensing bonders: Dispensing bonders are used to apply a specific amount of bonding agent to the surface of the materials being bonded.

9. How do you calibrate a bonder?

- Pressure calibration: The pressure calibration ensures that the bonder is applying the correct amount of pressure to the materials being bonded.

- Temperature calibration: The temperature calibration ensures that the bonder is applying the correct amount of heat to the materials being bonded.

- Speed calibration: The speed calibration ensures that the bonder is applying the bonding agent at the correct speed.

10. What are the safety precautions that must be taken when using a bonder?

- Wear proper protective equipment: Wear gloves, safety glasses, and a respirator when using a bonder.

- Ventilate the work area: The work area should be well-ventilated to prevent the build-up of fumes.

- Handle bonding agents with care: Bonding agents can be toxic and should be handled with care.

- Dispose of waste materials properly: Waste materials from the bonding process should be disposed of properly according to local regulations.

11. What is the role of a bonderizer in the bonding process?

- The bonderizer is responsible for preparing the surface of the materials to be bonded, applying the bonding agent, and curing the bond.

- The bonderizer must be familiar with the different types of bonding agents and the bonding process.

- The bonderizer must also be able to calibrate and maintain the bonding equipment.

12. What are the qualifications required to become a bonderizer?

- A high school diploma or equivalent

- Experience in the bonding process

- Knowledge of the different types of bonding agents

- Ability to calibrate and maintain bonding equipment

13. What are the career opportunities for a bonderizer?

- Bonders: Bonders are responsible for operating bonding machines and applying bonding agents to the surface of materials.

- Bonding technicians: Bonding technicians are responsible for setting up and maintaining bonding equipment.

- Bonding engineers: Bonding engineers are responsible for developing and designing bonding processes.

14. What is the salary range for a bonderizer?

- The salary range for a bonderizer can vary depending on experience, location, and company size.

- According to Glassdoor, the average salary for a bonderizer in the United States is $38,000 per year.

15. What are the challenges of being a bonderizer?

- The challenges of being a bonderizer can include working with hazardous chemicals, working in a fast-paced environment, and meeting production deadlines.

- Bonders must also be able to work independently and as part of a team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bonderizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bonderizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Bonderizer is an essential member of the metal finishing industry, responsible for preparing metal surfaces for subsequent coating or painting. Their key job responsibilities include:

1. Surface Preparation

Begins with thorough cleaning and degreasing of metal surfaces to remove contaminants and ensure proper adhesion of bonders and coatings.

2. Bonder Application

Applies chemical bonding agents to metal surfaces to enhance adhesion between the metal and subsequent coatings, ensuring long-lasting protection.

3. Inspection and Quality Control

Rigorously inspects treated surfaces to ensure adherence to quality standards, identifying and correcting any defects or imperfections.

4. Maintenance and Equipment Operation

Maintains and operates bonderizing equipment, including chemical baths, sprayers, and drying ovens, ensuring optimal performance and efficiency.

5. Environmental Compliance

Adheres to environmental regulations and guidelines in the handling and disposal of chemicals used in the bonderizing process.

6. Troubleshooting and Problem Solving

Identifies and resolves issues with the bonderizing process, determining the root cause and implementing corrective actions to maintain production efficiency.

Interview Tips

To ace the interview for a Bonderizer position, it is essential to prepare thoroughly and showcase your skills and knowledge. Here are some tips to help you succeed:

1. Research the Company and Industry

Gain insights into the company’s business, products, and industry trends. This demonstrates your interest and willingness to contribute to their goals.

2. Practice Common Interview Questions

Anticipate questions related to your experience, technical skills, and problem-solving abilities. Prepare thoughtful answers that highlight your strengths and relevance to the role.

3. Highlight Your Technical Expertise

Emphasize your knowledge of bonderizing techniques, chemical properties, and equipment operation. Showcase your understanding of industry standards and best practices.

4. Demonstrate Problem-Solving Skills

Describe instances where you identified and resolved issues in a bonderizing process. This showcases your analytical and troubleshooting abilities.

5. Ask Thoughtful Questions

Prepare insightful questions that demonstrate your engagement and interest in the role and company. Ask about the company’s growth plans, industry challenges, or opportunities for professional development.

6. Be Enthusiastic and Professional

Convey your passion for the industry and eagerness to contribute to the team. Maintain a positive and professional demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bonderizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!