Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bonderizer Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bonderizer Operator so you can tailor your answers to impress potential employers.

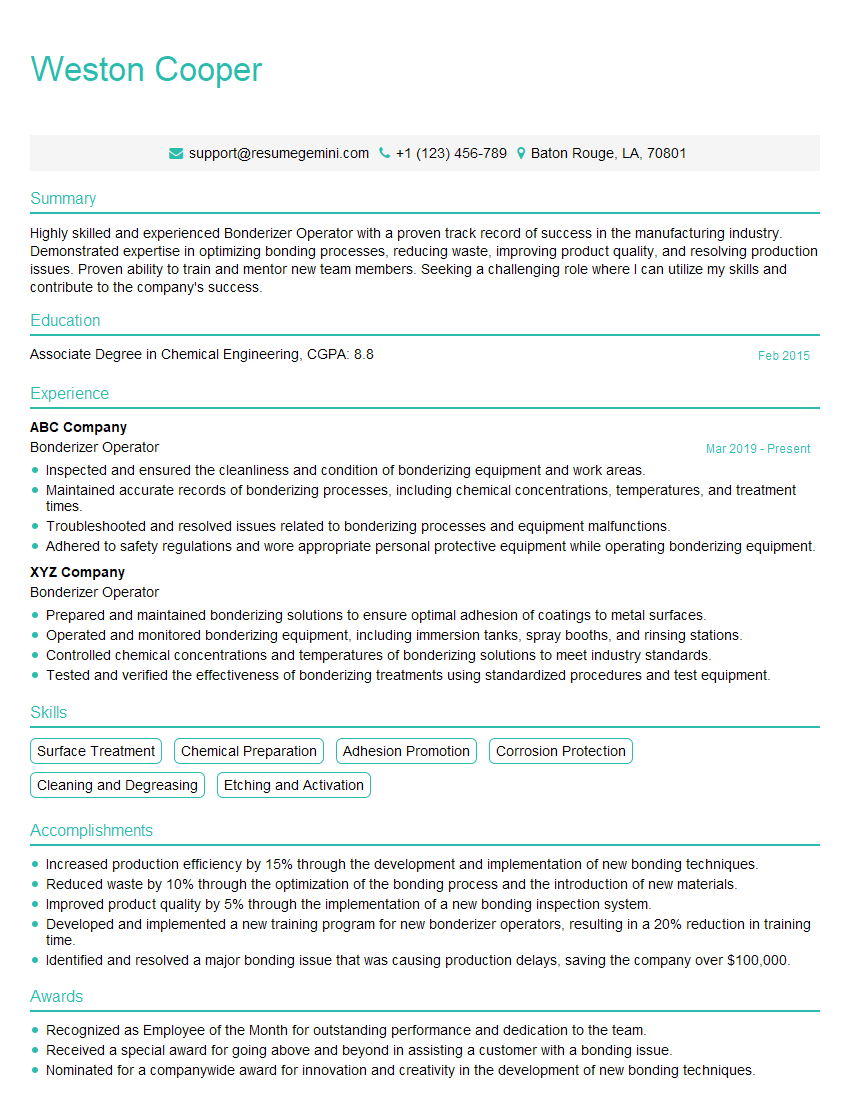

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bonderizer Operator

1. What is the purpose of bonderizing?

- Improve the adhesion of paint or other coatings to metal surfaces.

- Enhance corrosion resistance and durability.

- Provide a uniform surface for further processing.

2. Describe the process steps involved in bonderizing?

Pre-treatment

- Degreasing: Removing oils and dirt from the surface.

- Etching: Creating a rough surface for better coating adhesion.

Bonderizing Treatment

- Applying a chemical solution to the surface.

- Forming a phosphate conversion coating.

Post-treatment

- Rinsing: Removing excess chemicals.

- Drying: Removing moisture from the surface.

3. List the key quality control parameters in bonderizing?

- Coating weight or thickness

- Adhesion to the substrate

- Corrosion resistance

- Uniformity and appearance

- pH and chemical concentration of solutions

4. How do you maintain the quality of bonderized surfaces?

- Regularly monitoring and adjusting process parameters.

- Maintaining proper chemical concentrations and pH levels.

- Inspecting surfaces for defects and non-conformances.

- Implementing corrective actions when necessary.

- Adhering to established quality standards and procedures.

5. What are the different types of bonderizing solutions?

- Zinc phosphate

- Manganese phosphate

- Iron phosphate

- Calcium phosphate

- Chemical conversion coatings (chromates, oxides)

6. How do you troubleshoot common bonderizing problems?

- Poor adhesion: Check surface preparation, solution concentration, or process timing.

- Corrosion issues: Verify coating thickness, surface cleanliness, or post-treatment procedures.

- Non-uniform coating: Inspect solution agitation, spray nozzles, or workpiece position.

- Spots or stains: Identify and eliminate sources of contamination or surface defects.

- Improper rinse: Ensure adequate water flow and avoid chemical carryover.

7. Discuss the safety precautions essential while working with bonderizing chemicals?

- Wear appropriate personal protective equipment (PPE): Gloves, safety glasses, and overalls.

- Handle chemicals according to MSDS guidelines.

- Ensure proper ventilation and exhaust systems.

- Follow lock-out/tag-out procedures during maintenance.

- Dispose of waste chemicals and rinse water safely.

8. Describe your experience in operating and maintaining bonderizing equipment?

- Preparation and set up of equipment, including solution mixing and adjustments.

- Monitoring and control of process parameters, such as temperature, pH, and concentration.

- Loading and unloading workpieces, ensuring proper positioning and contact.

- Troubleshooting and resolving equipment malfunctions, minimizing downtime.

- Maintaining equipment cleanliness, performing regular inspections, and preventive maintenance.

9. Explain how you ensure the proper disposal of bonderizing waste?

- Separate spent solutions, rinse water, and solid waste for appropriate disposal methods.

- Neutralize acidic or alkaline waste before disposal.

- Comply with local regulations and environmental guidelines.

- Maintain accurate records of waste generation and disposal.

- Work with certified waste management companies.

10. How do you stay up-to-date with industry best practices and advancements in bonderizing technology?

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Consult with experts and suppliers.

- Participate in continuous training and development programs.

- Explore new technologies and innovations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bonderizer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bonderizer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bonderizer Operators are responsible for the operation and maintenance of a bonderizing line, which applies a chemical coating to metal surfaces to improve their adhesion, corrosion resistance, and paint adhesion. Key job responsibilities include:

1. Preparing and cleaning metal surfaces

• Cleaning metal surfaces to remove dirt, oil, and other contaminants

• Etching metal surfaces to create a rougher surface for better adhesion

2. Operating bonderizing line

• Loading metal parts onto the bonderizer line

• Controlling the temperature, pressure, and chemical composition of the bonderizing solution

• Monitoring the line for any problems

3. Inspecting finished parts

• Visually inspecting finished parts for any defects

• Testing the adhesion of the bonderized coating

4. Maintaining bonderizing line

• Cleaning and maintaining the bonderizing line

• Calibrating and repairing equipment

• Troubleshooting and resolving problems

5. Adhering to safety and environmental regulations

• Following all safety procedures

• Wearing appropriate personal protective equipment

• Properly disposing of hazardous waste

Interview Tips

To prepare for an interview for a Bonderizer Operator position, candidates should:

1. Research the company and position

• Visit the company website and learn about its products, services, and culture.

• Read the job description carefully and note the key requirements.

2. Practice answering common interview questions

• Prepare answers to common interview questions, such as:

- Tell me about your experience operating a bonderizing line.

- How do you ensure the quality of the finished parts

- What are the safety procedures for working with hazardous chemicals

3. Be prepared to discuss your skills and experience

• Highlight your skills and experience that are relevant to the position.

• Quantify your accomplishments whenever possible.

4. Dress appropriately

• Dress professionally for the interview.

• First impressions matter, so make sure you look your best.

5. Be confident and enthusiastic

• Be confident in your abilities and enthusiastic about the position.

• Employers are looking for candidates who are passionate about their work.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bonderizer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!