Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Bonding Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Bonding Molder so you can tailor your answers to impress potential employers.

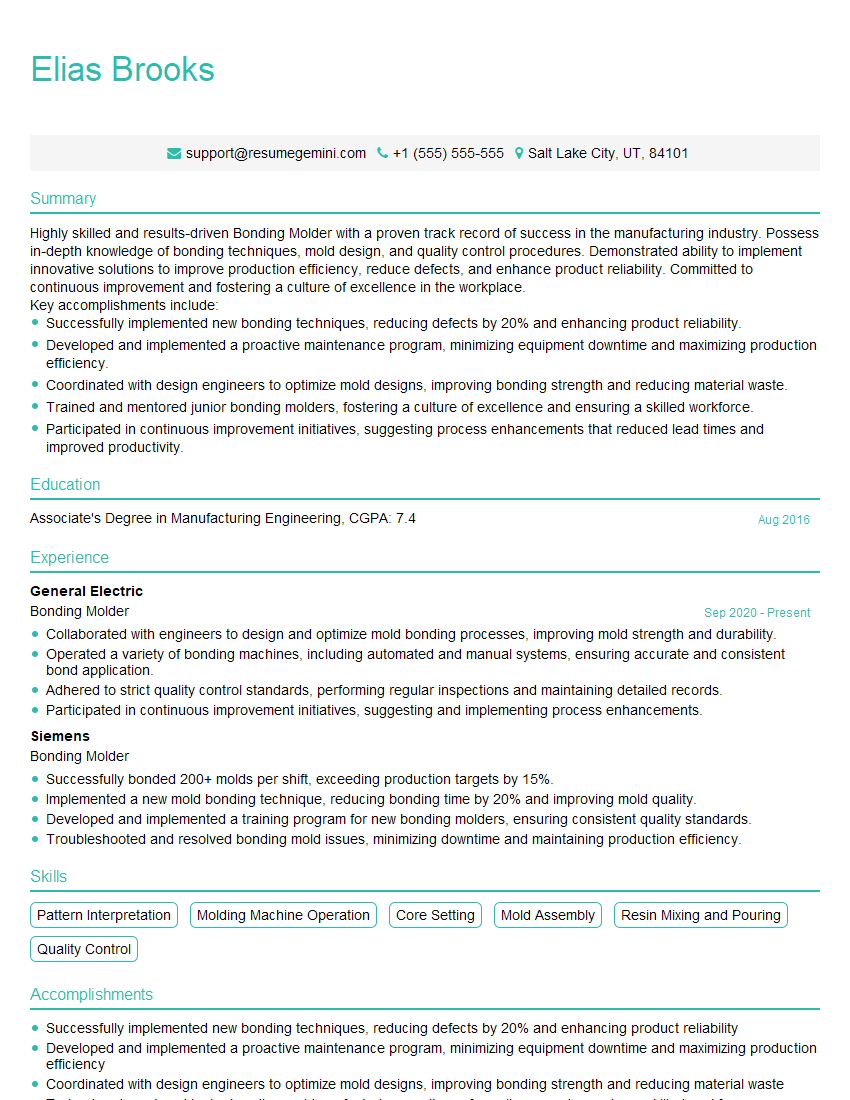

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bonding Molder

1. Explain the different types of bonding materials used in the bonding process?

In the bonding process, various types of bonding materials are utilized, each with unique characteristics. These materials include:

- Epoxies: Known for their exceptional strength, durability, and resistance to chemicals and solvents.

- Silicones: Curing into flexible, heat-resistant bonds, silicones are ideal for applications involving vibration or movement.

- Acrylics: Rapid-curing and versatile, acrylics form strong bonds with a variety of materials, including plastics and metals.

- Polyurethanes: Offering a combination of strength, flexibility, and adhesion, polyurethanes are suitable for a wide range of bonding applications.

- Anaerobics: Curing in the absence of air, anaerobics are commonly used to seal threads, gaskets, and other components.

2. Describe the key steps involved in the bonding process?

Surface Preparation:

- Ensuring clean and contaminant-free surfaces is crucial for optimal bond strength. Degreasing, abrasion, and chemical etching techniques may be employed.

Bonding Material Selection:

- Choosing the appropriate bonding material depends on factors such as material compatibility, bond strength requirements, and environmental conditions.

Bonding Application:

- Applying the bonding material correctly is essential. Factors to consider include proper mixing ratios, precise dispensing, and controlled application methods.

Curing:

- The curing process transforms the bonding material into a solid, durable bond. Curing conditions, such as temperature, time, and pressure, must be carefully controlled.

Quality Control:

- Inspecting the bonded joints for defects and ensuring they meet specifications is crucial for ensuring product reliability.

3. What are the common defects that can occur in the bonding process and how do you prevent them?

Common defects in the bonding process include:

- Poor adhesion: Resulting from inadequate surface preparation or incompatible bonding materials.

- Voids and bubbles: Caused by entrapped air or improper application techniques.

- Cracking: Occurring due to excessive stress, improper curing, or material incompatibility.

Prevention measures include:

- Thorough surface preparation.

- Selecting suitable bonding materials.

- Precise application and controlled curing.

- Implementing quality control procedures to detect and correct defects.

4. How do you ensure the quality and reliability of bonded joints?

Ensuring the quality and reliability of bonded joints involves:

- Material qualification: Testing bonding materials to verify their properties and compatibility.

- Process control: Establishing and adhering to standardized bonding procedures.

- Equipment calibration: Ensuring bonding equipment, such as dispensers and curing ovens, is calibrated and maintained.

- Operator training: Providing training to ensure proper bonding techniques are followed.

- Quality inspection: Performing inspections to identify and correct defects.

5. What are the safety precautions that must be taken when handling bonding materials?

Handling bonding materials requires adherence to safety precautions, including:

- Proper ventilation: Ensuring adequate ventilation to prevent exposure to harmful fumes.

- Personal protective equipment: Wearing gloves, eye protection, and respirators as necessary.

- Safe storage and handling: Storing bonding materials in designated areas and handling them according to manufacturer’s instructions.

- Waste disposal: Disposing of used bonding materials and equipment in an environmentally responsible manner.

6. Describe the different testing methods used to evaluate the performance of bonded joints?

Evaluating the performance of bonded joints involves various testing methods, such as:

- Tensile testing: Measuring the strength of a bond under tension.

- Shear testing: Determining the bond’s resistance to shear forces.

- Peel testing: Assessing the bond’s ability to resist peeling forces.

- Fatigue testing: Evaluating the bond’s durability under repeated loading.

- Environmental testing: Exposing bonded joints to different environmental conditions to assess their stability.

7. What is the role of surface preparation in the bonding process?

Surface preparation plays a crucial role in the bonding process by:

- Removing contaminants: Cleaning surfaces removes dirt, oil, and other contaminants that can interfere with bond formation.

- Increasing surface area: Roughening surfaces increases the surface area available for bonding, enhancing adhesion.

- Activating surfaces: Chemical treatments or plasma cleaning can activate surfaces, improving their ability to bond.

8. Explain the factors that influence the curing process of bonding materials.

Factors influencing the curing process of bonding materials include:

- Temperature: Curing rates increase with higher temperatures.

- Time: Longer curing times allow for stronger bond formation.

- Humidity: Moisture can affect the curing process of some bonding materials.

- Bonding thickness: Thicker bonds require longer curing times.

- Curing method: Different curing methods, such as heat curing or UV curing, have varying effects on curing rates.

9. Describe the considerations for selecting a bonding material for a specific application?

Selecting a bonding material involves considering factors such as:

- Material compatibility: The bonding material must be compatible with the materials being bonded.

- Bond strength requirements: The bonding material must provide sufficient strength for the intended application.

- Environmental conditions: The bonding material must withstand the environmental conditions the bond will be exposed to.

- Curing time and temperature: The curing time and temperature must be compatible with the production process.

- Cost and availability: The cost and availability of the bonding material are important considerations.

10. Explain the importance of quality control in the bonding process.

Quality control in the bonding process is essential for ensuring:

- Consistent bond quality: Quality control ensures that bonded joints meet specified standards.

- Product reliability: High-quality bonds enhance product reliability and performance.

- Reduced defects: Quality control helps identify and correct defects, minimizing product failures.

- Customer satisfaction: Delivering quality bonded products leads to customer satisfaction and repeat business.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bonding Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bonding Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities:

Bonding Molders are highly skilled professionals responsible for creating intricate molds used in various industries, including automotive, aerospace, and manufacturing.

1. Mold Making:

The primary responsibility of a Bonding Molder is to create molds using bonding materials, typically epoxies or urethanes.

- Interpret blueprints and design specifications to determine mold requirements.

- Mix and apply bonding materials to form mold patterns according to specifications.

- Ensure proper curing and finishing of molds to meet quality standards.

2. Quality Control:

Bonding Molders are responsible for maintaining the quality of their molds.

- Perform dimensional inspections and measurements to ensure accuracy.

- Identify and correct any defects or imperfections in the mold.

- Maintain records of mold inspections and repairs.

3. Production Management:

Bonding Molders may be responsible for managing mold production schedules.

- Monitor mold production progress and identify potential bottlenecks.

- Coordinate with other departments, such as design and manufacturing, to ensure timely mold delivery.

- Maintain a clean and organized work area.

4. Communication and Collaboration:

Bonding Molders often work closely with other professionals.

- Communicate with design engineers to clarify specifications and discuss mold design.

- Collaborate with production staff to provide guidance on mold usage and maintenance.

- Participate in training and development programs to stay updated on industry best practices.

Interview Preparation Tips:

To ace the interview for a Bonding Molder position, candidates should be well-prepared and demonstrate their skills and experience.

1. Research the Company and Industry:

Research the company’s history, products, and industry trends.

- This will help you understand their business and show the interviewer that you are genuinely interested in the position.

- For example, if you are interviewing for a Bonding Molder position in the automotive industry, research recent advancements in automotive mold-making technology.

2. Practice Your Technical Skills:

Bonding Molding is a highly technical field. Practice your skills in mold design, materials selection, and quality control.

- For instance, you could create mock-up molds or perform dimensional inspections on existing molds.

- This will help you build your confidence and demonstrate your proficiency to the interviewer.

3. Showcase Your Experience:

Emphasize your previous experience in Bonding Molding.

- Highlight your accomplishments, such as creating complex molds for high-volume production or developing innovative mold-making techniques.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

4. Prepare Questions for the Interviewer:

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Ask about the company’s mold-making capabilities, the specific mold requirements for the position, or the opportunities for professional development.

- This shows the interviewer that you are eager to learn and contribute to the team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bonding Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!