Feeling lost in a sea of interview questions? Landed that dream interview for Bone Char Kiln Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bone Char Kiln Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

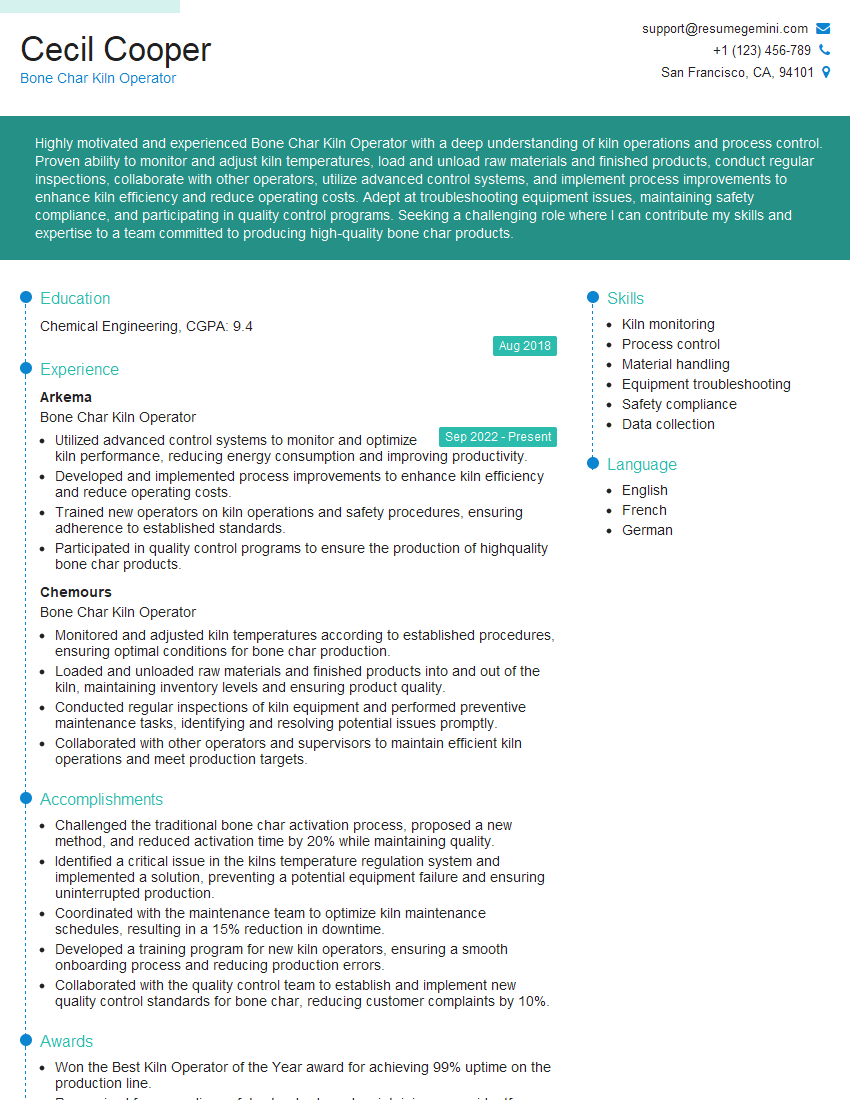

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bone Char Kiln Operator

1. Describe the process of operating a bone char kiln?

The process of operating a bone char kiln includes the following steps:

- Loading the kiln with bone char.

- Heating the kiln to the desired temperature.

- Maintaining the temperature for the desired amount of time.

- Cooling the kiln.

- Unloading the kiln.

2. What are the different types of bone char kilns?

There are two main types of bone char kilns: rotary kilns and vertical kilns.

Rotary kilns

- Rotary kilns are long, cylindrical kilns that rotate on their axis.

- The bone char is fed into the kiln at one end and is heated as it travels through the kiln.

- The hot gases from the kiln are used to preheat the incoming bone char.

Vertical kilns

- Vertical kilns are tall, cylindrical kilns that are loaded with bone char from the top.

- The bone char is heated by hot gases that are passed through the kiln from the bottom.

- The hot gases from the kiln are used to preheat the incoming bone char.

3. What are the critical control points in the operation of a bone char kiln?

The critical control points in the operation of a bone char kiln are:

- The temperature of the kiln.

- The residence time of the bone char in the kiln.

- The cooling rate of the bone char.

4. What are the safety precautions that must be taken when operating a bone char kiln?

The safety precautions that must be taken when operating a bone char kiln include:

- Wearing appropriate personal protective equipment (PPE).

- Following the proper operating procedures.

- Being aware of the potential hazards associated with the operation of a bone char kiln.

5. What are the environmental regulations that apply to the operation of a bone char kiln?

The environmental regulations that apply to the operation of a bone char kiln include:

- The Clean Air Act.

- The Clean Water Act.

- The Resource Conservation and Recovery Act.

6. What is the role of bone char in the sugar refining process?

Bone char is used in the sugar refining process to remove impurities from sugar liquor.

- The bone char adsorbs the impurities onto its surface.

- The sugar liquor is then filtered through the bone char to remove the impurities.

- The bone char can be regenerated by heating it to a high temperature.

7. What are the different grades of bone char?

There are three main grades of bone char:

- Raw bone char.

- Activated bone char.

- Spent bone char.

8. How is bone char disposed of?

Bone char can be disposed of in a landfill or by incineration.

- Landfilling is the most common method of disposal.

- Incineration is a more expensive method of disposal, but it can be used to generate energy.

9. What are the advantages of using bone char in the sugar refining process?

The advantages of using bone char in the sugar refining process include:

- Bone char is a very effective adsorbent.

- Bone char can be regenerated and reused multiple times.

- Bone char is a relatively inexpensive material.

10. What are the disadvantages of using bone char in the sugar refining process?

The disadvantages of using bone char in the sugar refining process include:

- Bone char is a by-product of the meat industry, which some people find objectionable.

- Bone char can contain harmful contaminants, such as lead and arsenic.

- Bone char can be difficult to dispose of.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bone Char Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bone Char Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Supervise and Manage the Kiln Operation

The Bone Char Kiln Operator is responsible for the supervision and management of all aspects of the kiln operation, including:

- Monitoring and adjusting the temperature, pressure, and other operating parameters of the kiln to ensure optimal performance.

- Maintaining the kiln equipment and ensuring its proper operation.

- Ensuring the safety of the kiln operation and compliance with all applicable regulations.

2. Monitor and Control the Production Process

The Bone Char Kiln Operator is responsible for monitoring and controlling the production process, including:

- Loading and unloading the kiln with raw materials and finished products.

- Monitoring the quality of the bone char produced and making adjustments to the process as needed.

- Maintaining records of the production process and product quality.

3. Perform Maintenance and Repairs

The Bone Char Kiln Operator is responsible for performing maintenance and repairs on the kiln and associated equipment, including:

- Identifying and diagnosing problems with the kiln and associated equipment.

- Performing routine maintenance and repairs to keep the kiln and equipment in good working order.

- Coordinating with maintenance personnel for major repairs or overhauls.

4. Comply with Safety and Environmental Regulations

The Bone Char Kiln Operator is responsible for complying with all applicable safety and environmental regulations, including:

- Wearing appropriate personal protective equipment (PPE).

- Following safe work practices and procedures.

- Maintaining a clean and orderly work area.

Interview Tips

Preparing for an interview is essential to making a great impression and increasing your chances of success. Here are some tips to help you prepare for your Bone Char Kiln Operator interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Bone Char Kiln Operator.

- Visit the company’s website and social media pages.

- Read industry news and articles to learn about the latest trends and developments.

- Prepare questions to ask the interviewer about the company and the position.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Brainstorm a list of potential interview questions.

- Write out your answers to each question.

- Practice delivering your answers out loud to a friend or family member.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for an office setting. You should also arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose an outfit that is clean, pressed, and appropriate for an office setting.

- Arrive for your interview on time.

4. Be Confident and Enthusiastic

Confidence is key in an interview. When you are confident, you will come across as more capable and qualified for the position. Enthusiasm is also important, as it shows that you are passionate about the job and the company.

- Maintain eye contact with the interviewer.

- Speak clearly and confidently.

- Demonstrate your enthusiasm for the position and the company.

5. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the position and the company. It is also a chance to show the interviewer that you are interested and engaged.

- Prepare a few questions to ask the interviewer.

- Ask questions that are relevant to the position and the company.

- Listen carefully to the interviewer’s answers.

6. Follow Up

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are still a candidate. You can follow up by sending a thank-you note or email to the interviewer.

- Send a thank-you note or email to the interviewer within 24 hours of the interview.

- Reiterate your interest in the position and the company.

- Thank the interviewer for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bone Char Kiln Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!