Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Boom Pump Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

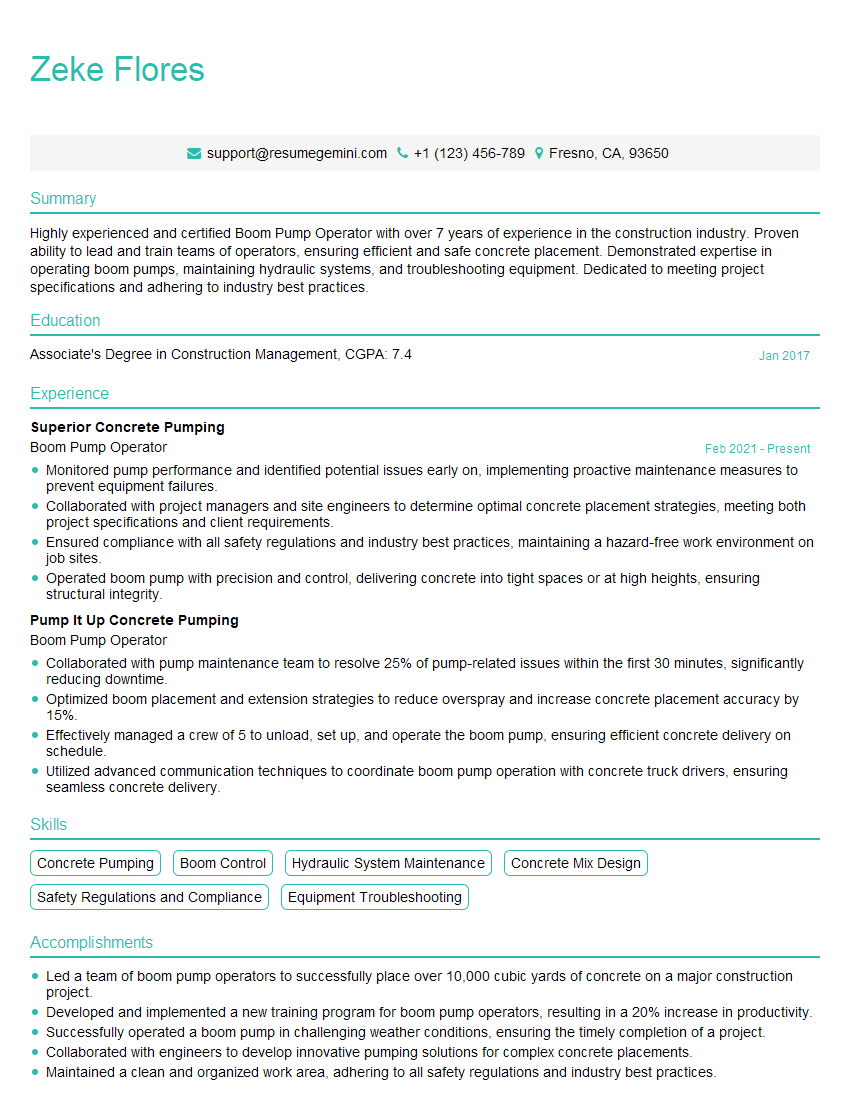

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boom Pump Operator

1. What are the key responsibilities of a Boom Pump Operator?

- Operate and maintain a boom pump, ensuring it is in good working condition.

- Control the flow of concrete from the pump to the placement area.

- Monitor the concrete mix and make adjustments as needed.

- Communicate with other crew members and supervisors to ensure smooth operation.

- Inspect and maintain equipment regularly to prevent breakdowns.

2. Describe the different types of concrete boom pumps.

Stationary Boom Pumps

- Remain in one fixed location and pump concrete to surrounding areas.

- Can have a vertical or horizontal boom.

Truck-Mounted Boom Pumps

- Mounted on a truck chassis for increased mobility.

- Can reach higher elevations than stationary pumps.

Line Pumps

- Used to pump concrete over long distances.

- Consist of a series of pumps connected by pipelines.

3. How do you determine the correct boom pump for a specific job?

- Consider the volume of concrete to be pumped.

- Assess the distance and height the concrete needs to be pumped.

- Determine the accessibility of the job site.

- Consult with the project engineer or supervisor for specific requirements.

4. What safety precautions should be taken when operating a boom pump?

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Inspect the equipment before each use and ensure it is in good working order.

- Establish a safe work zone around the pump.

- Never operate the pump under power lines or near other hazards.

- Be aware of your surroundings and communicate clearly with other crew members.

5. What are the common maintenance tasks for a boom pump?

- Greasing and oiling moving parts.

- Inspecting and replacing worn or damaged hoses and pipes.

- Checking and adjusting hydraulic pressure.

- Cleaning the pump and hopper regularly.

- Following manufacturer’s recommended maintenance schedule.

6. How do you troubleshoot a boom pump that is not working properly?

- Identify the potential cause of the issue (e.g., power failure, hydraulic leak, concrete blockage).

- Refer to the manufacturer’s manual or consult with an experienced mechanic.

- Check for any loose connections, leaks, or damaged components.

- Attempt to clear blockages or make minor repairs as necessary.

- If the issue persists, call for professional assistance.

7. What factors affect the performance of a boom pump?

- Concrete mix design (slump, aggregate size, additives).

- Ambient temperature and humidity.

- Pump pressure and flow rate.

- Boom length and configuration.

- Operator skill and experience.

8. How do you minimize concrete waste when using a boom pump?

- Accurately estimate the amount of concrete needed.

- Use a hopper extension to reduce spills.

- Clean the boom and hopper thoroughly after use.

- Return any unused concrete to the supplier.

9. What is the importance of proper communication when operating a boom pump?

- Ensures smooth coordination between crew members.

- Reduces the risk of accidents and errors.

- Facilitates problem-solving and efficient troubleshooting.

- Improves overall productivity and safety on the job site.

10. Describe a situation where you successfully resolved a problem while operating a boom pump.

- Describe the problem encountered, including symptoms and potential causes.

- Explain the steps taken to diagnose the issue.

- Discuss the solution implemented and its effectiveness.

- Highlight your problem-solving skills and ability to work under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boom Pump Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boom Pump Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boom Pump Operators are responsible for operating and maintaining boom pumps, which are used to place concrete in construction projects. They must be able to work independently and as part of a team, and they must be able to follow instructions and work safely.

1. Operating the Boom Pump

Boom Pump Operators must be able to operate the boom pump safely and efficiently. This includes being able to control the boom, the pump, and the concrete flow. They must also be able to troubleshoot any problems that may arise.

- Control the boom pump’s movements.

- Pump concrete at the correct rate and pressure.

2. Maintaining the Boom Pump

Boom Pump Operators must be able to maintain the boom pump in good working order. This includes performing daily inspections, greasing the machine, and making minor repairs. They must also be able to identify any potential problems and report them to their supervisor.

- Perform daily inspections of the boom pump.

- Grease the machine and make minor repairs.

3. Safety

Boom Pump Operators must be able to work safely. This includes following all safety regulations, wearing appropriate safety gear, and being aware of their surroundings. They must also be able to identify and avoid potential hazards.

- Follow all safety regulations.

- Wear appropriate safety gear.

- Identify and avoid potential hazards.

4. Teamwork

Boom Pump Operators often work as part of a team. They must be able to communicate effectively with other team members and work together to get the job done. They must also be able to take direction from their supervisor.

- Communicate effectively with other team members.

- Work together to get the job done.

- Take direction from their supervisor.

Interview Tips

Preparing for an interview for a Boom Pump Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Before your interview, take some time to research the company you’re applying to. This will help you understand their business, their culture, and their needs. You can find information about the company on their website, in their social media profiles, and in news articles.

- Visit the company’s website.

- Check out their social media profiles.

- Read news articles about the company.

2. Practice Your Answers

Once you’ve done your research, it’s time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions for Boom Pump Operators include:

- Tell me about your experience operating boom pumps.

- What are your strengths and weaknesses as a Boom Pump Operator?

- How do you handle working in a team environment?

- What are your safety procedures when operating a boom pump?

- What are your career goals?

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you’re applying for. You should also arrive on time for your interview and be prepared to answer questions about your experience and qualifications.

- Wear clean, pressed clothes.

- Dress appropriately for the job you’re applying for.

- Arrive on time for your interview.

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident, honest, and enthusiastic, and you’ll be sure to make a good impression.

- Be confident.

- Be honest.

- Be enthusiastic.

Next Step:

Now that you’re armed with the knowledge of Boom Pump Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Boom Pump Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini