Feeling lost in a sea of interview questions? Landed that dream interview for Bore Mill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bore Mill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

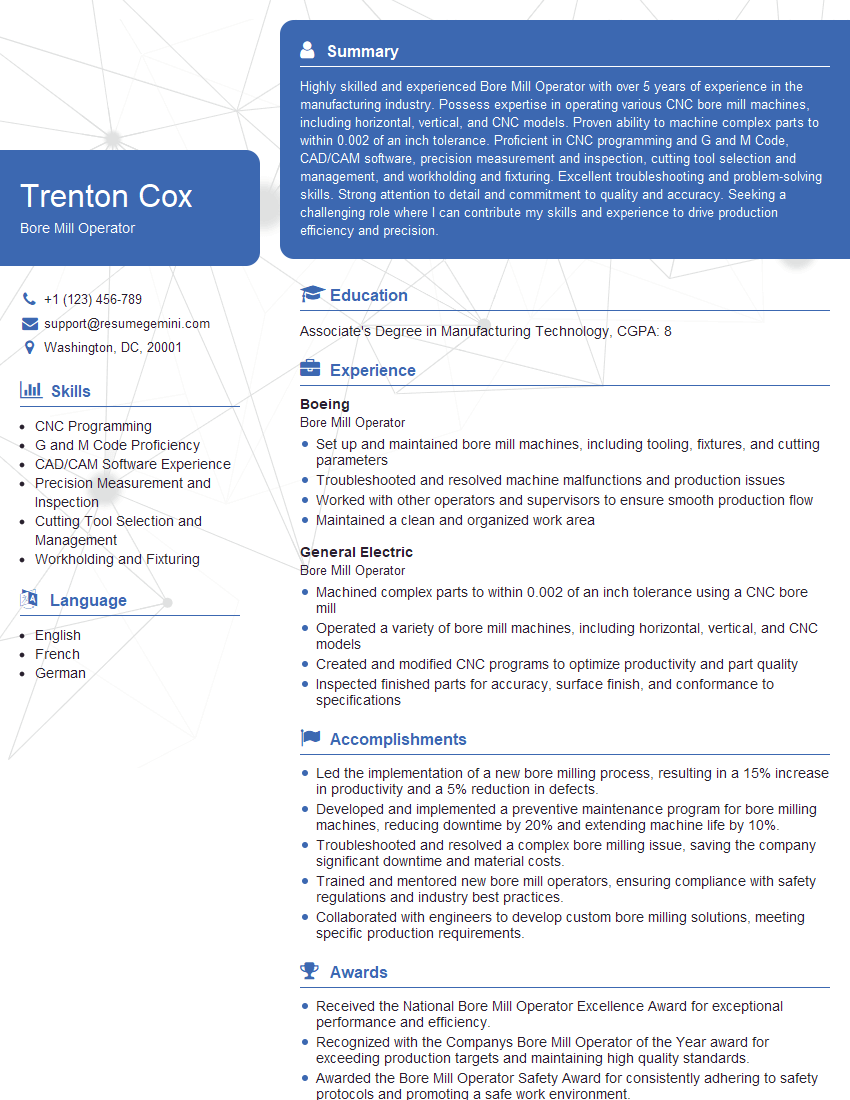

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bore Mill Operator

1. What are the different types of boring machines?

There are various types of boring machines, including:

- Horizontal boring machine

- Vertical boring machine

- Jig boring machine

- CNC boring machine

2. What are the key considerations when selecting a boring machine?

Factors to consider:

- Size and complexity of the workpiece

- Required accuracy and precision

- Production volume and time constraints

- Available budget

3. Describe the process of setting up a boring machine for a new job.

Setting up a boring machine for a new job involves:

- Mounting the workpiece securely

- Selecting and installing the appropriate cutting tool

- Setting the correct spindle speed and feed rate

- Programming the machine (if using a CNC machine)

4. What are the common problems that can occur during boring operations and how do you troubleshoot them?

- Problem: Excessive vibration

- Troubleshooting: Check for unbalanced workpiece, worn tool, or incorrect spindle speed

- Problem: Poor surface finish

- Troubleshooting: Use a sharper tool, reduce feed rate, or increase spindle speed

5. How do you ensure the accuracy and precision of bored holes?

- Use high-quality cutting tools

- Set the correct spindle speed and feed rate

- Check and adjust tool offsets regularly

- Use precision measuring tools to verify hole dimensions

6. What are the safety precautions that must be followed when operating a boring machine?

- Wear appropriate safety gear

- Keep the work area clean and organized

- Follow proper machine operating procedures

- Inspect the machine regularly for any potential hazards

7. What are the different types of cutting tools used in boring operations?

- Single-point boring tools

- Multi-point boring tools

- Boring bars

- Boring heads

8. How do you determine the optimal spindle speed and feed rate for a boring operation?

Optimal spindle speed and feed rate depend on:

- Material being bored

- Tool geometry

- Hole size and depth

- Desired surface finish

9. How do you perform surface boring operations?

- Mount the workpiece on the machine table

- Select a boring tool with the appropriate diameter

- Set the spindle speed and feed rate

- Move the tool to the desired starting position

- Lower the tool into the workpiece and begin boring

10. What are the advantages of using CNC boring machines?

- Improved accuracy and precision

- Increased productivity

- Reduced setup time

- Automated operation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bore Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bore Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Bore Mill Operator

Bore mill operators are responsible for operating boring mills to create precise holes in metal parts. Their primary job duties include:

1. Machine Operation and Maintenance

- Setting up and operating boring mills to machine holes in metal parts

- Monitoring machine operations to ensure precision and efficiency

- Performing routine maintenance and repairs on boring mills

2. Part Preparation and Inspection

- Selecting and installing cutting tools and fixtures

- Loading and unloading workpieces

- Inspecting finished parts to ensure quality

3. Measurement and Calculation

- Using measuring tools and instruments to determine dimensions

- Performing calculations to determine cutting parameters

- Reading blueprints and technical drawings

4. Safety and Quality Control

- Following safety procedures and guidelines

- Maintaining a clean and organized work area

- Adhering to quality standards and specifications

Interview Tips for Bore Mill Operator

To prepare for an interview for a Bore Mill Operator position, candidates should consider the following tips:

1. Research the Company and Role

- Learn about the company’s history, products, and services

- Research the specific role and its responsibilities

- Identify the key skills and experience required for the position

2. Practice Answering Common Interview Questions

- Prepare answers to common interview questions such as:

- “Tell me about yourself”

- “Why are you interested in this role?”

- “What are your strengths and weaknesses?”

3. Highlight Relevant Skills and Experience

- Tailor your resume and cover letter to emphasize skills relevant to the role

- Provide specific examples of your experience that demonstrate your abilities

- Quantify your accomplishments to showcase your impact

4. Be Prepared to Talk About Safety

- Safety is a crucial aspect of being a Bore Mill Operator

- Discuss your knowledge of safety protocols and your commitment to maintaining a safe work environment

- Share examples of how you have implemented safety measures in previous roles

5. Show Enthusiasm and Motivation

- Convey your passion for machining and your desire to excel in this role

- Express your willingness to learn new skills and take on additional responsibilities

- Demonstrate your commitment to precision, quality, and continuous improvement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bore Mill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!