Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Borematic Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

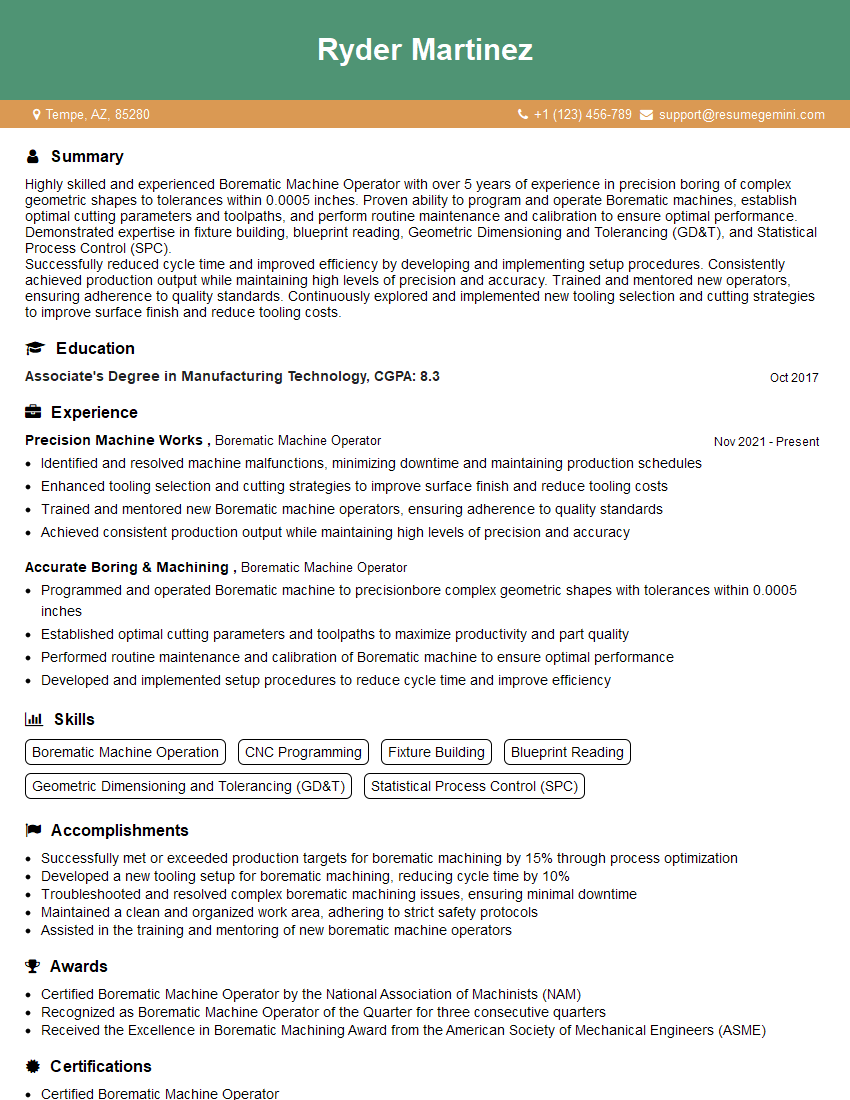

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Borematic Machine Operator

1. What are the different types of borematic machines and their applications?

Borematic machines come in various types, each designed for specific applications. Here are some common types:

- Horizontal Borematic Machine: Used for precision boring large workpieces, often used in heavy industries like shipbuilding and oil and gas.

- Vertical Borematic Machine: Suitable for boring holes in vertical orientations, often used in automotive and aerospace industries.

- Jig Boring Machine: High-precision machines used for accurate hole production, often used in toolmaking and component manufacturing.

- Portable Borematic Machine: Compact and portable, these machines are used for on-site or field applications, such as pipeline and valve maintenance.

2. Explain the process of setting up a borematic machine for a specific job.

Boring Bar Selection

- Select the appropriate boring bar based on the hole size, workpiece material, and required tolerance.

Tooling and Workpiece Setup

- Mount the boring bar in the machine spindle and set the cutting tool to the correct depth.

- Secure the workpiece on the machine table or fixture to ensure stability and accuracy.

Machine Parameters

- Set the machine parameters, including spindle speed, feed rate, and coolant flow, based on the workpiece material and desired surface finish.

3. How do you ensure that the borematic machine maintains high accuracy during operation?

Maintaining accuracy is crucial in borematic operations. Here are some key practices:

- Calibration and Inspection: Regularly calibrate the machine to ensure spindle runout, alignment, and measurement accuracy.

- Tooling Maintenance: Use sharp and properly maintained cutting tools to achieve precise cuts and prevent errors.

- Temperature Control: Monitor and control the temperature of the machine and workpiece to minimize thermal expansion and maintain stability.

- Vibration Damping: Employ vibration damping techniques to minimize external vibrations and ensure smooth machine operation.

4. What are the common problems encountered in borematic operations and how do you troubleshoot them?

Borematic operations may encounter various problems. Troubleshooting involves identifying the root cause and taking appropriate corrective actions:

- Poor Surface Finish: Check for blunt tools, insufficient coolant, or vibrations in the machine or workpiece.

- Dimensional Inaccuracy: Inspect the setup, tooling alignment, and machine parameters. Calibrate the machine if necessary.

- Excessive Tool Wear: Analyze the workpiece material, cutting speed, and feed rate. Adjust parameters or consider using specialized tools.

- Chattering: Check for imbalances in the machine or workpiece, improper tool setup, or excessive chip accumulation.

5. How do you optimize borematic operations for efficiency and productivity?

Optimizing borematic operations involves maximizing output while maintaining quality. Here are some strategies:

- Tool Selection and Setup: Choose the most appropriate tools and ensure proper setup to minimize tool changes and downtime.

- Process Optimization: Optimize cutting parameters, cycle times, and tool paths to achieve the desired results efficiently.

- Automation: Implement automation techniques, such as CNC programming, to reduce manual labor and increase consistency.

- Preventive Maintenance: Perform regular maintenance and inspections to prevent breakdowns and ensure optimal machine performance.

6. Describe the different types of cutting tools used in borematic operations and their applications.

Borematic operations utilize various cutting tools, each designed for specific applications:

- Single-Point Boring Tools: Used for creating precise holes with high accuracy and surface finish.

- Multi-Point Boring Tools: Enable faster material removal and are suitable for roughing operations.

- Boring Heads: Allow for precise hole enlargement and can accommodate multiple cutting inserts.

- Trepanning Tools: Used for creating deep holes with minimal material waste.

7. How do you measure and inspect the accuracy of bored holes?

Accuracy inspection in borematic operations is crucial to ensure component quality:

- Dimensional Measurement: Use precision measuring instruments, such as calipers, micrometers, or coordinate measuring machines (CMMs), to verify hole size, depth, and positional accuracy.

- Surface Finish Inspection: Employ surface roughness testers or optical comparators to assess the surface quality and identify any imperfections.

- Geometric Inspection: Utilize specialized tools, such as taper gauges or roundness testers, to check for deviations from specified geometric tolerances.

8. What are the safety precautions that must be observed when operating a borematic machine?

Safety is paramount in borematic operations. Here are some essential precautions:

- Proper Training: Ensure thorough training on machine operation and safety procedures.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, earplugs, and gloves, to protect against hazards.

- Machine Guarding: Verify that all machine guards and safety devices are in place and functional.

- Work Area Maintenance: Keep the work area clean and organized to minimize tripping or slipping hazards.

9. How do you interpret engineering drawings and specifications for borematic operations?

Understanding engineering drawings and specifications is essential for accurate and efficient borematic operations:

- Drawing Interpretation: Analyze the drawing to comprehend the workpiece design, dimensions, tolerances, and surface finish requirements.

- Specification Review: Study the specifications to determine material properties, cutting parameters, and any special instructions.

- Tool Selection: Based on the drawing and specifications, select the appropriate tools and setup parameters to achieve the desired results.

10. What is your approach to continuous improvement and staying updated on advancements in borematic technology?

Continuous improvement and staying abreast of technological advancements are crucial in the manufacturing industry:

- Training and Education: Attend industry workshops, conferences, and training programs to enhance knowledge and skills.

- Industry Publications: Read technical journals and articles to stay informed about new techniques, materials, and technologies.

- Collaboration and Networking: Engage with colleagues, industry experts, and equipment manufacturers to exchange ideas and learn from their experiences.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Borematic Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Borematic Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Borematic Machine Operators are responsible for the operation and maintenance of borematic machines, which are used to create precise holes in metal parts. Key responsibilities include:

1. Machine Operation

Setting up and operating borematic machines according to specifications.

- Loading and unloading parts.

- Monitoring machine performance and adjusting as needed.

2. Quality Control

Ensuring the quality of parts produced by the borematic machine.

- Inspecting parts for accuracy and dimensions.

- Identifying and correcting defects.

3. Machine Maintenance

Performing routine maintenance on borematic machines to ensure optimal performance.

- Cleaning and lubricating machines.

- Replacing worn or damaged parts.

4. Safety

Following all safety procedures and regulations.

- Wearing appropriate protective gear.

- Operating machines in a safe manner.

Interview Tips

Preparing for an interview for a Borematic Machine Operator position can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to stay up-to-date on the latest trends and technologies.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare for questions about your experience, skills, and qualifications.

- Develop examples of how you have successfully completed tasks related to the job.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for a business setting.

- Choose clothing that is comfortable and allows you to move freely.

- Avoid wearing clothing that is too revealing or distracting.

4. Be Punctual

Punctuality is important for any job interview, but it is especially important for a Borematic Machine Operator position. This shows the interviewer that you are reliable and respectful of their time.

- Plan your route to the interview in advance to avoid getting lost or delayed.

- Give yourself plenty of time to get to the interview location.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Borematic Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.