Are you gearing up for a career in Borematic Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Borematic Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

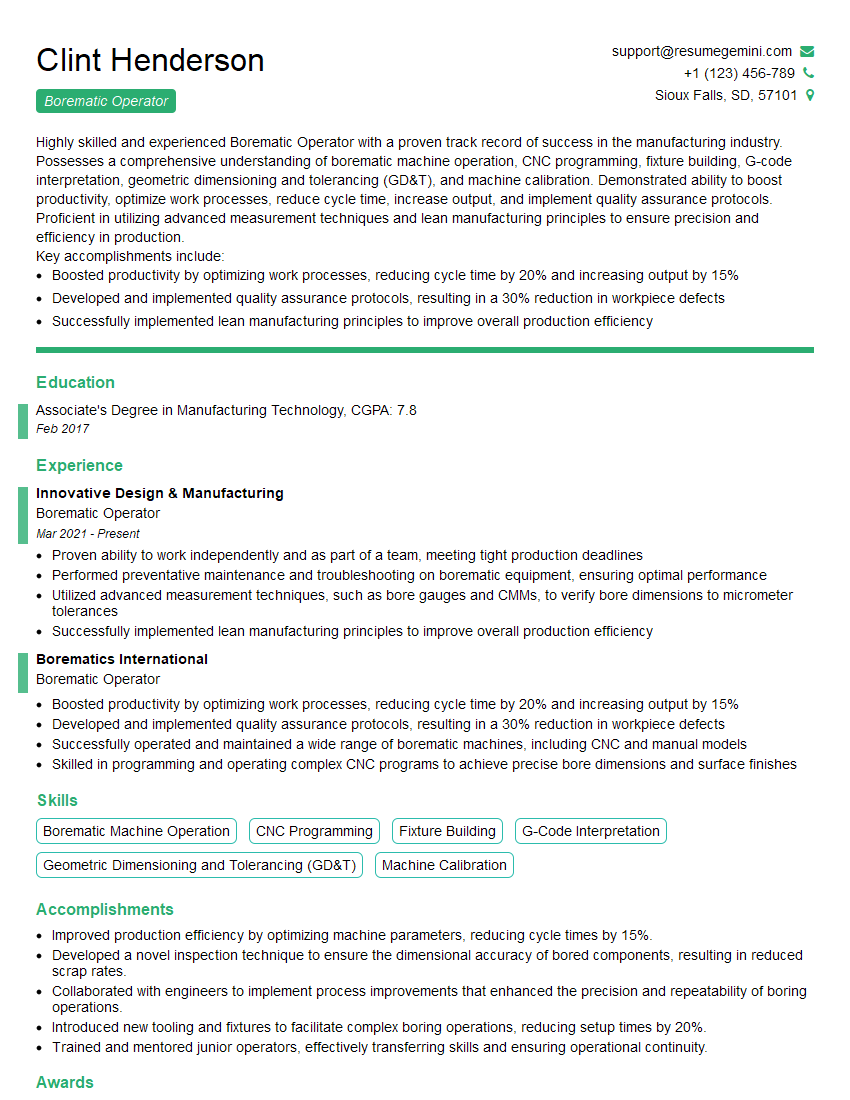

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Borematic Operator

1. Can you tell me about your experience as a Borematic Operator?

In my previous role as a Borematic Operator, I was responsible for operating and maintaining a borematic machine used for precision boring operations. My key responsibilities included:

- Setting up and operating the borematic machine according to specifications.

- Monitoring the machine’s performance and making necessary adjustments to ensure accurate and efficient operation.

- Performing routine maintenance and troubleshooting to keep the machine in optimal working condition.

2. What are some of the quality standards you have to adhere to when operating a borematic machine?

- Dimensional accuracy and tolerances as per engineering drawings.

- Surface finish requirements, including roughness and waviness.

- Geometric tolerances, such as concentricity, parallelism, and perpendicularity.

- Material specifications and heat treatment requirements.

3. How do you ensure the accuracy and repeatability of your borematic operations?

To ensure the accuracy and repeatability of my borematic operations, I follow these key practices:

- Thoroughly inspect the workpiece and tooling before starting the operation.

- Use precision measuring instruments to verify dimensions and alignments.

- Follow established setup procedures and reference points.

- Monitor the machine’s performance and make adjustments as needed.

- Regularly calibrate the machine and its tooling.

4. How do you troubleshoot common problems that may arise when operating a borematic machine?

When troubleshooting common problems with a borematic machine, I follow these steps:

- Identify the problem and its symptoms.

- Check for any loose connections or worn components.

- Examine the workpiece and tooling for damage or defects.

- Review the machine’s settings and make necessary adjustments.

- Consult with a supervisor or maintenance technician if the issue persists.

5. How do you maintain a clean and organized work area around your borematic machine?

To maintain a clean and organized work area around my borematic machine, I follow these practices:

- Regularly clean the machine and its surroundings to remove debris.

- Keep tools and materials organized in designated areas.

- Dispose of waste and used materials promptly.

- Follow established safety procedures and wear appropriate personal protective equipment.

- Report any potential hazards or spills to a supervisor immediately.

6. What are some of the safety precautions you take when operating a borematic machine?

- Always wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and all guards are in place.

- Keep hands and loose clothing away from moving parts.

- Be aware of the machine’s operating limits and never exceed them.

- Follow established safety procedures and report any unsafe conditions or practices.

7. Can you tell me about a time when you had to work independently to solve a complex problem with a borematic machine?

In a previous project, I encountered a problem where the borematic machine was producing parts with inconsistent dimensions. After thoroughly inspecting the machine and tooling, I identified a worn-out spindle bearing as the cause. I replaced the bearing and recalibrated the machine, which resolved the issue and ensured accurate part production.

8. What are your expectations for this role as a Borematic Operator?

- To apply my skills and experience to operate and maintain borematic machines efficiently.

- To contribute to the team’s productivity and quality goals.

- To learn and grow professionally in the field of precision machining.

- To maintain a safe and organized work environment.

- To follow company policies and procedures and contribute to a positive work atmosphere.

9. How do you stay up-to-date on the latest advancements in borematic technology?

To stay up-to-date on the latest advancements in borematic technology, I engage in the following activities:

- Attend industry conferences and exhibitions.

- Read technical journals and online resources.

- Network with other borematic operators and engineers.

- Participate in training and development programs.

- Follow industry experts and thought leaders on social media.

10. What are your strengths and weaknesses as a Borematic Operator?

My strengths as a Borematic Operator include:

- Excellent technical skills and knowledge of borematic machines.

- Strong attention to detail and commitment to quality.

- Ability to troubleshoot and resolve complex problems independently.

- Experience in working effectively in a team environment.

- Willingness to learn and adapt to new challenges.

As for areas for improvement, I am actively working on:

- Expanding my knowledge of advanced borematic techniques.

- Improving my communication skills for effective collaboration.

- Seeking opportunities for professional development and certification.

11. What is your experience with different types of borematic machines?

I have experience working with a variety of borematic machines, including:

- Horizontal and vertical borematic machines

- Single- and multi-spindle borematic machines

- CNC-controlled and manually operated borematic machines

- Machines from various manufacturers

12. What is your preferred type of borematic machine to work with? Why?

I prefer to work with CNC-controlled borematic machines. They offer several advantages over manually operated machines, such as:

- Increased accuracy and repeatability

- Reduced setup times

- Improved efficiency and productivity

- Ability to handle complex geometries and contours

13. What is your experience with programming and operating CNC borematic machines?

I have experience programming and operating CNC borematic machines using various software platforms. I am proficient in creating and editing G-code programs, setting up work coordinates, and optimizing cutting parameters.

14. What are your quality control procedures for borematic operations?

My quality control procedures for borematic operations include:

- Visual inspection of workpieces before and after machining

- Dimensional measurement using precision measuring instruments

- Surface finish measurement using roughness testers

- Geometric tolerance verification using coordinate measuring machines

15. What is your safety record as a Borematic Operator?

I have an excellent safety record as a Borematic Operator. I am fully aware of the potential hazards associated with borematic operations and take all necessary precautions to ensure my safety and the safety of others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Borematic Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Borematic Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Borematic Operators are responsible for operating and maintaining borematic machines, which are used to bore cylindrical holes in metal or other materials. Their key job responsibilities include:

1. Machine Operation and Maintenance

• Setting up and operating borematic machines

• Performing routine maintenance and repairs on borematic machines

• Calibrating and adjusting borematic machines to ensure accuracy

2. Quality Control

• Measuring and inspecting finished bores to ensure accuracy and quality

• Troubleshooting and resolving problems with bore quality

• Maintaining records of bore measurements and quality checks

3. Production

• Meeting or exceeding production targets

• Loading and unloading parts from borematic machines

• Monitoring borematic machines during operation

4. Safety and Housekeeping

• Complying with all safety regulations

• Maintaining a clean and organized work area

• Reporting any safety concerns or hazards

Interview Tips

To prepare for an interview for a Borematic Operator position, candidates should:

1. Research the Company and Position

• Visit the company’s website to learn about their products, services, and culture

• Read the job description carefully to understand the specific requirements and responsibilities of the position

2. Highlight Relevant Skills and Experience

• Emphasize any experience operating or maintaining borematic machines

• Describe your skills in quality control, production, and safety

• Provide examples of your ability to troubleshoot and resolve problems

3. Practice Common Interview Questions

• Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Use the STAR method (Situation, Task, Action, Result) to answer behavioral questions

4. Dress Professionally and Arrive On Time

• Make a good first impression by dressing professionally and arriving on time for your interview

• Be polite and respectful to everyone you meet, including the receptionist and other employees

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Borematic Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Borematic Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.